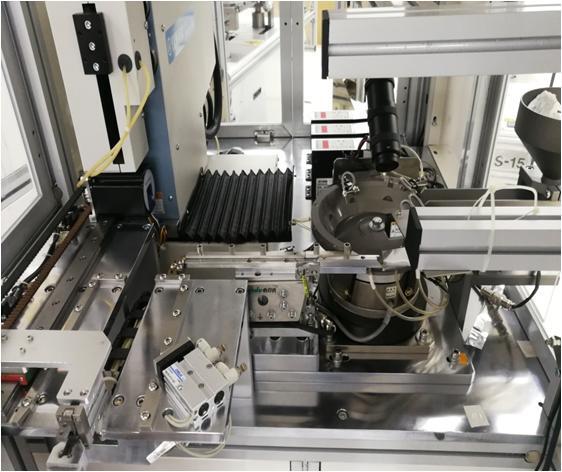

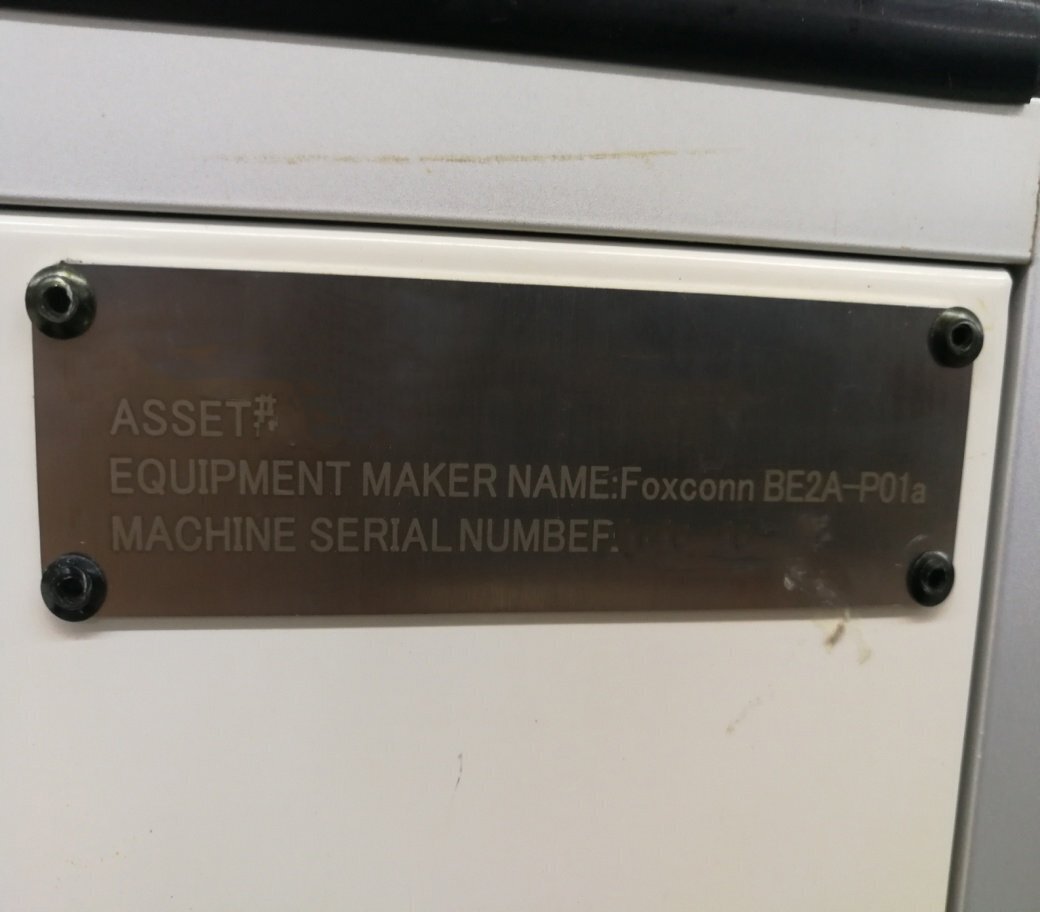

Used FOXCONN BE2A-P01a #9300796 for sale

URL successfully copied!

Tap to zoom

FOXCONN BE2A-P01a is a pc board assembly and manufacturing equipment developed by FOXCONN for the purpose of producing and assembling printed circuit boards (PCBs) of superior quality and in high volumes. It features a unique 5-axis robotic assembly platform, the first of its kind in the industry, that offers a multitude of advantages including production flexibility, higher mounting accuracy, shorter loading and unloading time, PCBA quality assurance, and cost-efficiency. In order to ensure reliable production throughput with minimal setup time, BE2A-P01a is equipped with an automated component placing system, intelligent vision inspection unit, and advanced surface mount process hardware. The machine is capable of handling a wide range of components, such as chip resistors, capacitors, connectors, and IC packages. The placement arm includes a high-tech vision tool with the ability to recognize various components and to detect misplacements. Additionally, the onboard automated programming asset allows for quick and accurate programming of each PCB. Further, FOXCONN BE2A-P01a features quick response printheads with laser distance sensors which are capable of producing up to three times the output of traditional methods. Its flexible high-speed camera enables fast recognition of various components, which ensures stable and fast operation. Meanwhile, the onboard Optical character recognition and adjacent component recognition software ensures reliability and accuracy. Additionally, BE2A-P01a is equipped with advanced production tools for efficient manufacturing. It is capable of supporting up to five types of tape feeders in the material library, which allows for unparalleled production flexibility. The onboard auto-color camera monitoring model ensures high-efficiency detection and reliable placement of components, while the patented high-power laser-scan microscope equipment offers superior accuracy and reliability. Finally, FOXCONN BE2A-P01a also features a friendly operation system, coupled with a user-friendly graphical interface for efficient production. The intuitive graphical interface allows for easy setup, parameter setting, and job scheduling. The onboard real-time monitoring unit further allows for complete traceability and provides accurate feedback on production status. Overall, BE2A-P01a from FOXCONN is the most advanced pc board assembly and manufacturing machine currently on the market. From its 5-axis robotic assembly platform to its advanced production tools, FOXCONN BE2A-P01a is a reliable and cost-effective solution for high-volume printed circuit board fabrication.

There are no reviews yet