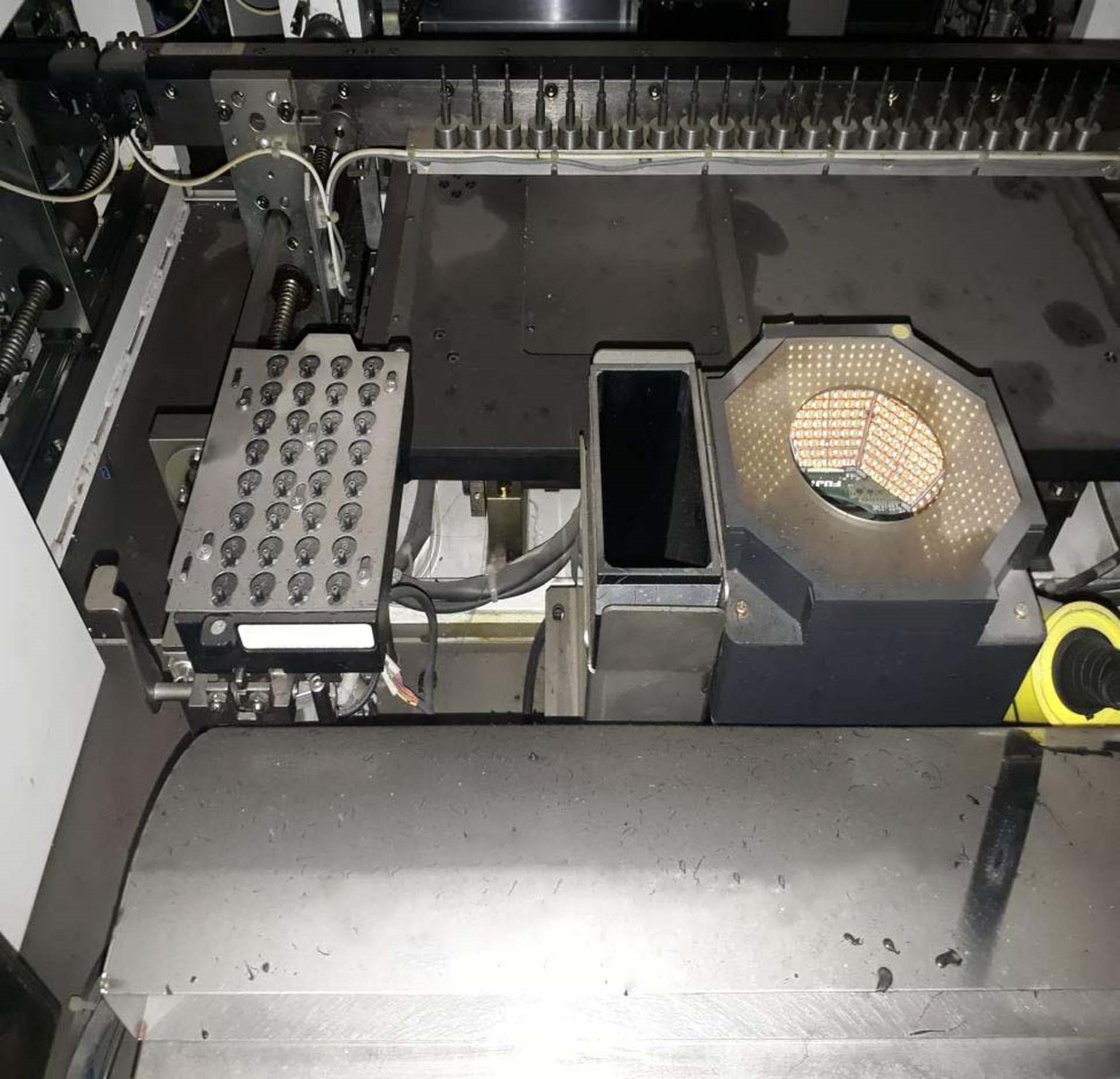

Used FUJI AIM #9224670 for sale

URL successfully copied!

Tap to zoom

ID: 9224670

Vintage: 2007

Pick and place machine

Feeders:

(16) 08w

(2) 24 mm

(5) 12 mm

(2) 16 mm

Heads:

(2) H12S

H04

H01

2007 vintage.

FUJI AIM is a comprehensive PC board assembly and manufacturing equipment developed by FUJI Electronic. It is designed to provide a comprehensive and versatile solution for PC board design, manufacturing, and assembly. The system works by integrating various software and hardware components that allow for efficient planning, production, and quality assurance of PC boards. Firstly, the software portion of AIM unit includes In-Circuit Design (ICD) and Code Design (CD) tools. These tools enable users to create sophisticated and highly reliable circuit boards by scheduling sequences of instructions and integrating parts efficiently. Additionally, by using these tools, users can create a variety of component interface and control sequences within the circuit board. Next, the hardware portion of the machine includes equipment such as Solder Reflow Ovens, Jet Printer, Routing Machine, Pattern Reader, In-line AOI, and Pick and Place Machine. This equipment is used to ensure that the components are correctly soldered, efficiently routed, and accurately laid out on the board. The soldering of components onto the board is done using the Reflow Oven which uses a controlled bake time and temperature to ensure a reliable circuit board. The Jet Printer is used to print the patterns that are used for routing on the board. The Routing Machine then routes the tracks on the board with a high level of precision while the Pattern Reader is used to check the correctness of the routing patterns. The In-Line AOI and Pick and Place Machine are used to detect any inaccuracies in the placement of components on the board. Finally, FUJI AIM also includes multiple modules making quality assurance and testing of the board assembly very easy. For example, there is the Nozzle Diag Check Module which is used to test the functionality of the nozzle's on the Pick and Place Machine and the Part Recognition module which checks all the parts on the board to ensure the accuracy of the placement. In summary, AIM is a comprehensive PC board assembly and manufacturing tool developed by FUJI Electronic. It integrates various software and hardware components that allow for efficient planning, production, and quality assurance of PC boards. By using this asset, users can create sophisticated and highly reliable circuit boards with minimal time and effort.

There are no reviews yet