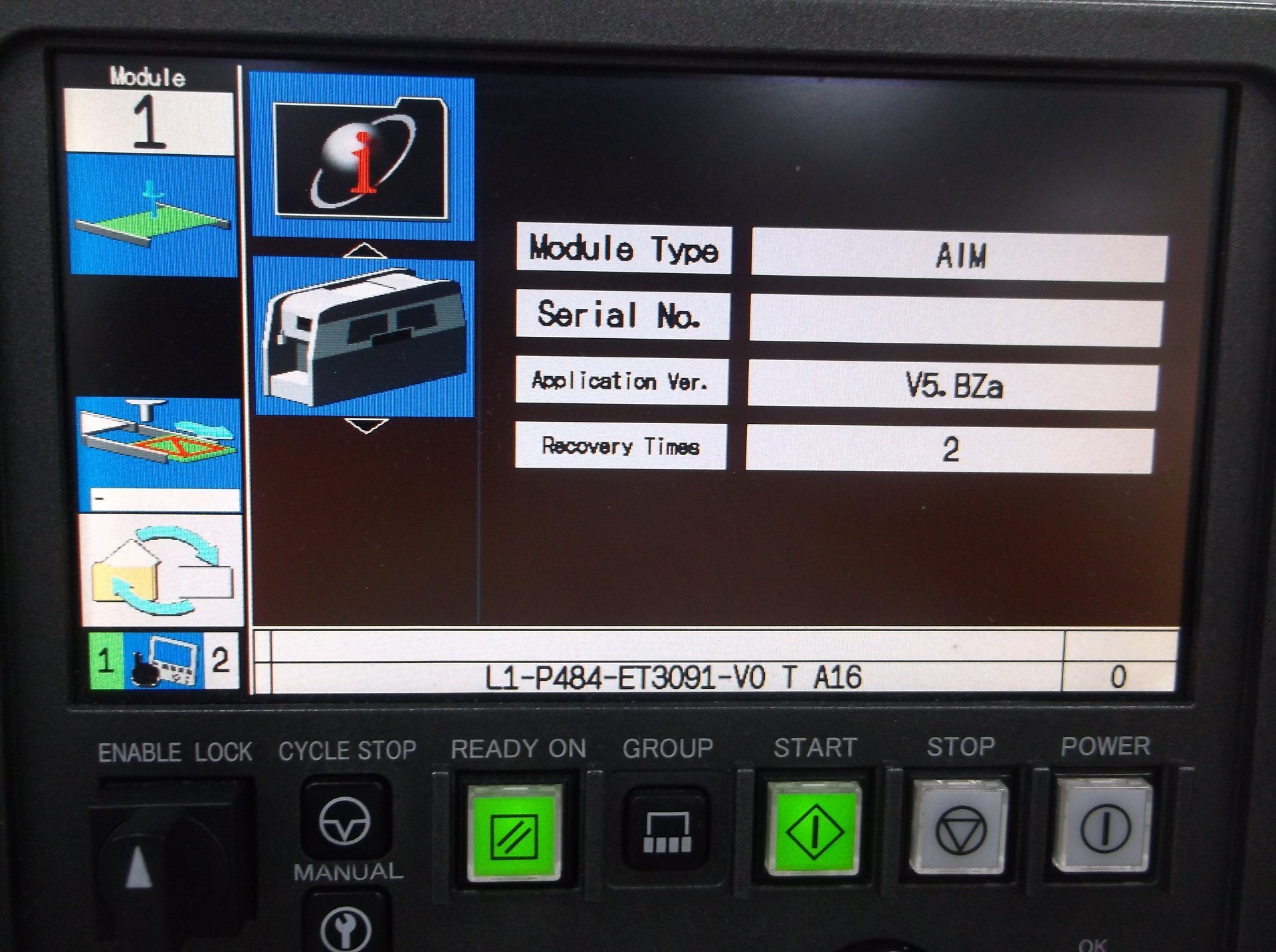

Used FUJI AIM #9268622 for sale

URL successfully copied!

Tap to zoom

ID: 9268622

Vintage: 2006

Pick and place machine

Hours: 43,175.8

Single lane conveyor

Feeder slots: 180 mm x 8 mm

Maximum PCB size: 508 mm x 356 mm

Placement heads: (4) H12

Tray and stick feeders

Adhesive dispensing head

2006 vintage.

FUJI AIM is a complete PC board assembly and manufacturing equipment that uses a high-speed head and its synchronous feeder system to enable accurate, precise board assembly. Utilizing an array of features, AIM helps assemblers optimize board throughput in various production outputs. The unit features a 20-slot tape feeder which can accommodate multiple tape sizes, giving flexibility for mounting onto components. Its high-speed head is capable of quickly and accurately mounting components as small as 0201. It also boasts up to 2 peak mm per second, meaning fewer parts are required to achieve larger production goals. FUJI AIM is also able to apply flux and active adhesion perfectly. The entire machine is based on PC control which ensures stable operation and easy data management/modification. The tool is equipped with a highly accurate and reliable vision asset for defect inspection, which helps improve efficiency and accuracy in board production. The vision model is further equipped with a zoom function and a ruler function that can measure board coordinates to a maximum of +/- 15 microns. In addition to its advanced hardware, AIM is also benefit from its user-friendly software program. The software is designed for user friendly operation and editing of program data, including parameters for monitoring and controlling all its features/options. FUJI AIM also provides the user with convenient data storage capabilities and a manufacturer label printing function. Data logging allows for easier and faster transfer of data through various production stages. In addition, the equipment's manufacturer label printing feature supports a wide variety of popular barcodes and allows for easy and accurate traceability. Overall, AIM is an industry leading system designed to enhance the accuracy, speed, and quality of board assembly and manufacturing operations. With its precise vision unit, efficient data logging capabilities, and its versatile software program, assemblers can optimize board throughput in various production outputs and maximize efficiency.

There are no reviews yet