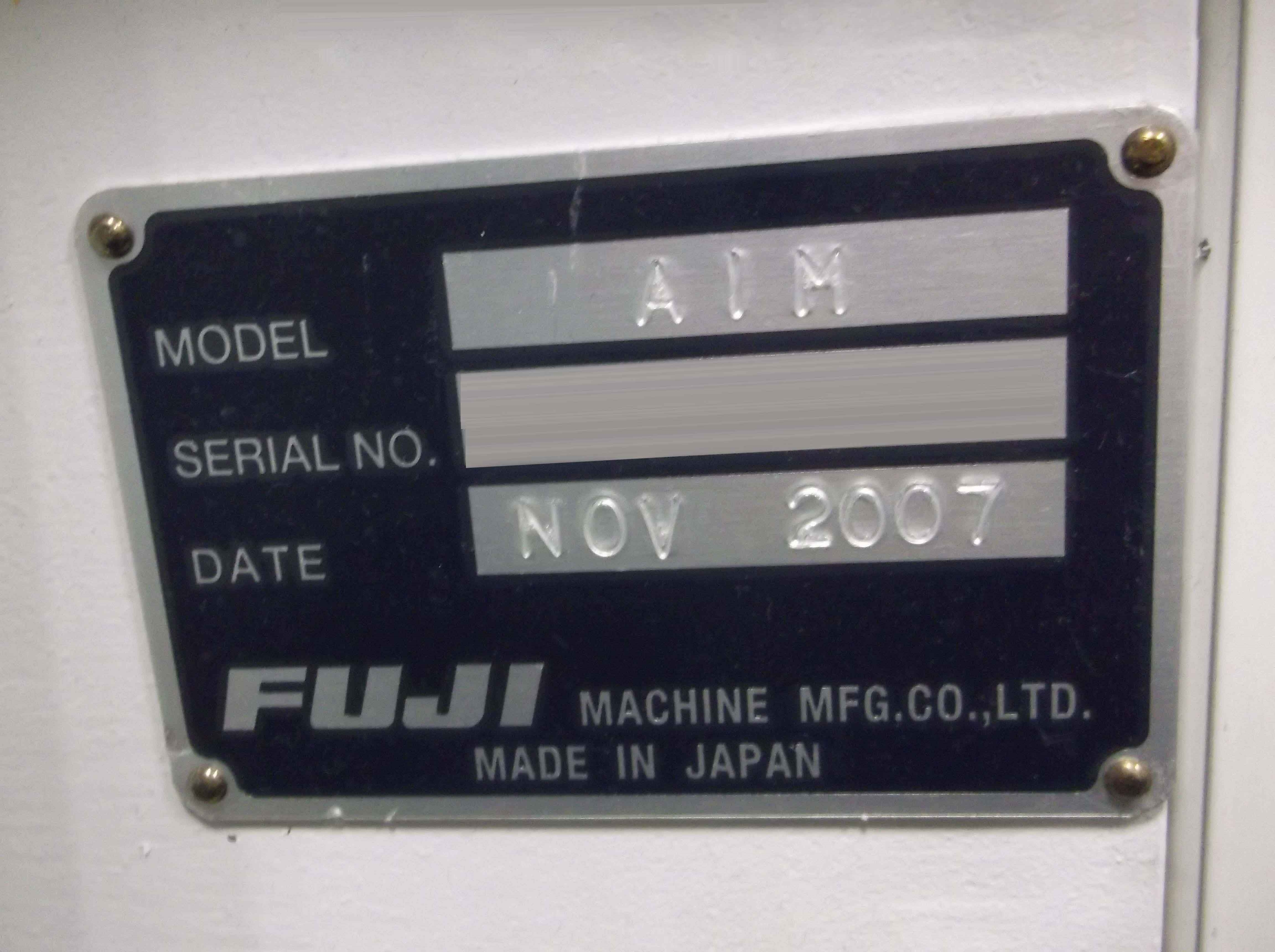

Used FUJI AIM #9268623 for sale

URL successfully copied!

Tap to zoom

ID: 9268623

Vintage: 2007

Pick and place machine

Hours: 37,611.8

Single lane conveyor

Feeder slots: 180 mm x 8 mm

Maximum PCB size: 508 mm x 356 mm

Placement heads:

(2) H08

(2) H04

Tray and stick feeders

Adhesive dispensing head

2007 vintage.

FUJI AIM is a pc board assembly and manufacturing equipment used by companies in various industries to produce quality boards with incredible accuracy. The system consists of a number of components including AIM software, equipment dedicated to board assembly and manufacturing, as well as precision verification tools. FUJI AIM software utilizes CAD data and 3D configuration software to quickly and accurately set up the production line and automate the production process. The unit is built for modern electronic production lines - by providing integration solutions and flexible production plans. This includes data management, automated error detection and correction, and process control capability. Additionally, it has the capability to accept any off-the-shelf I/O boards, and can be customized for use with any proprietary hardware components. AIM machine is also designed with an open architecture that enables the user to leverage existing industrial instrumentation for automation. The tool is configurable, allowing users to quickly customize equipment settings to meet their specific production need. The asset is also designed to provide a safe and accurate SMT production environment with features that allow users to monitor production performance at all times. The model also provides a unique way to process components with a single tape-and-reel loader that can handle a wide range of component sizes and types. This allows boards to be manufactured with fewer component changeovers, decreasing the possibility of errors during manufacturing. The equipment also has advanced systems for precise verification of component placement and reflow. This ensures boards are populated with the correct components and that components are placed accurately and reliably. This ensures that boards are produced with unmatched precision and accuracy. Overall, FUJI AIM system is designed for fast and accurate production and offers features that enable users to meet their production goals efficiently. It provides the safety and precision of an automated production line and is designed to reduce errors in manufacturing. By consistently producing quality boards, users can increase their profitability and reduce their operation costs.

There are no reviews yet