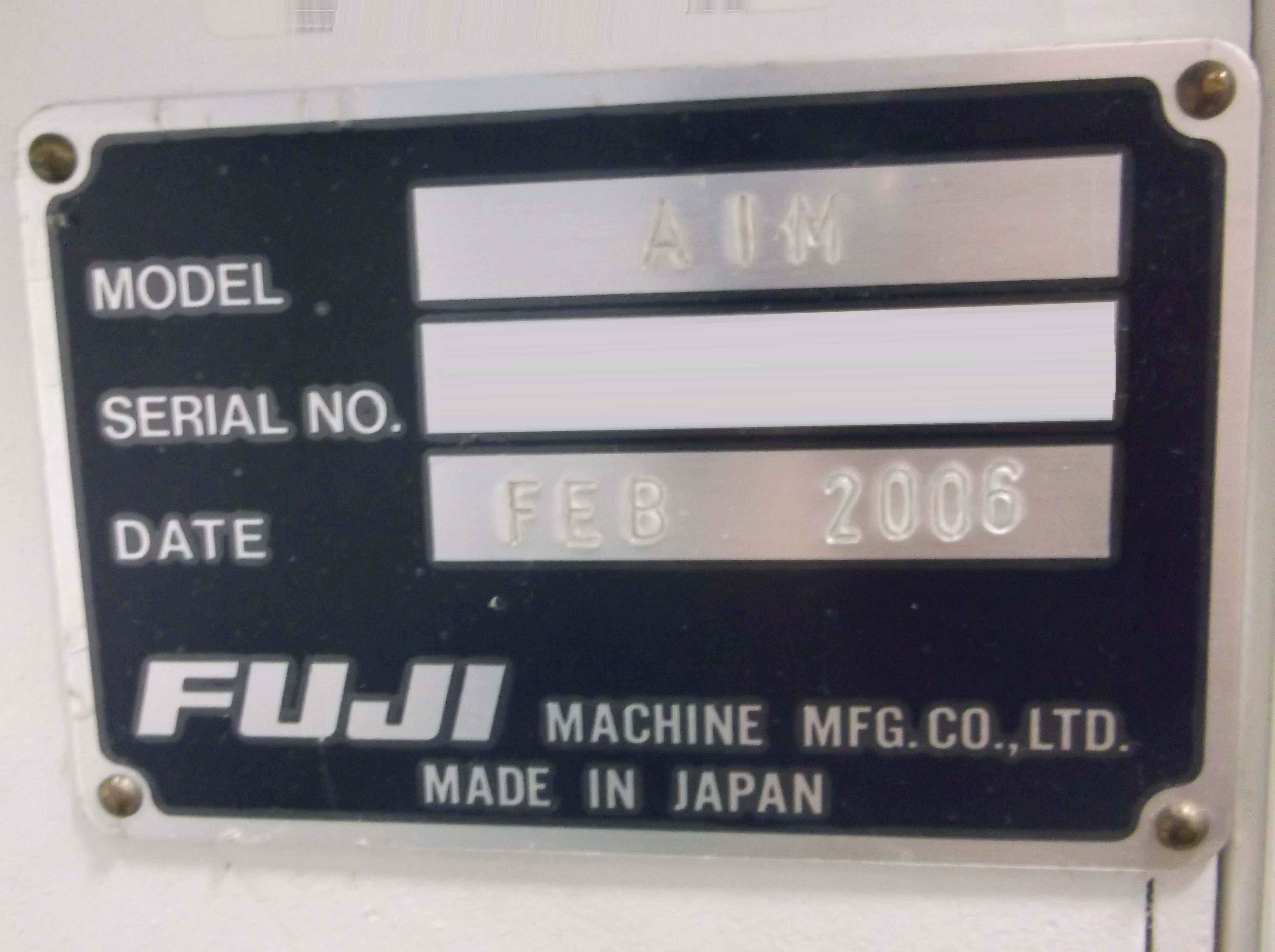

Used FUJI AIM #9268626 for sale

URL successfully copied!

Tap to zoom

ID: 9268626

Vintage: 2006

Pick and place machine

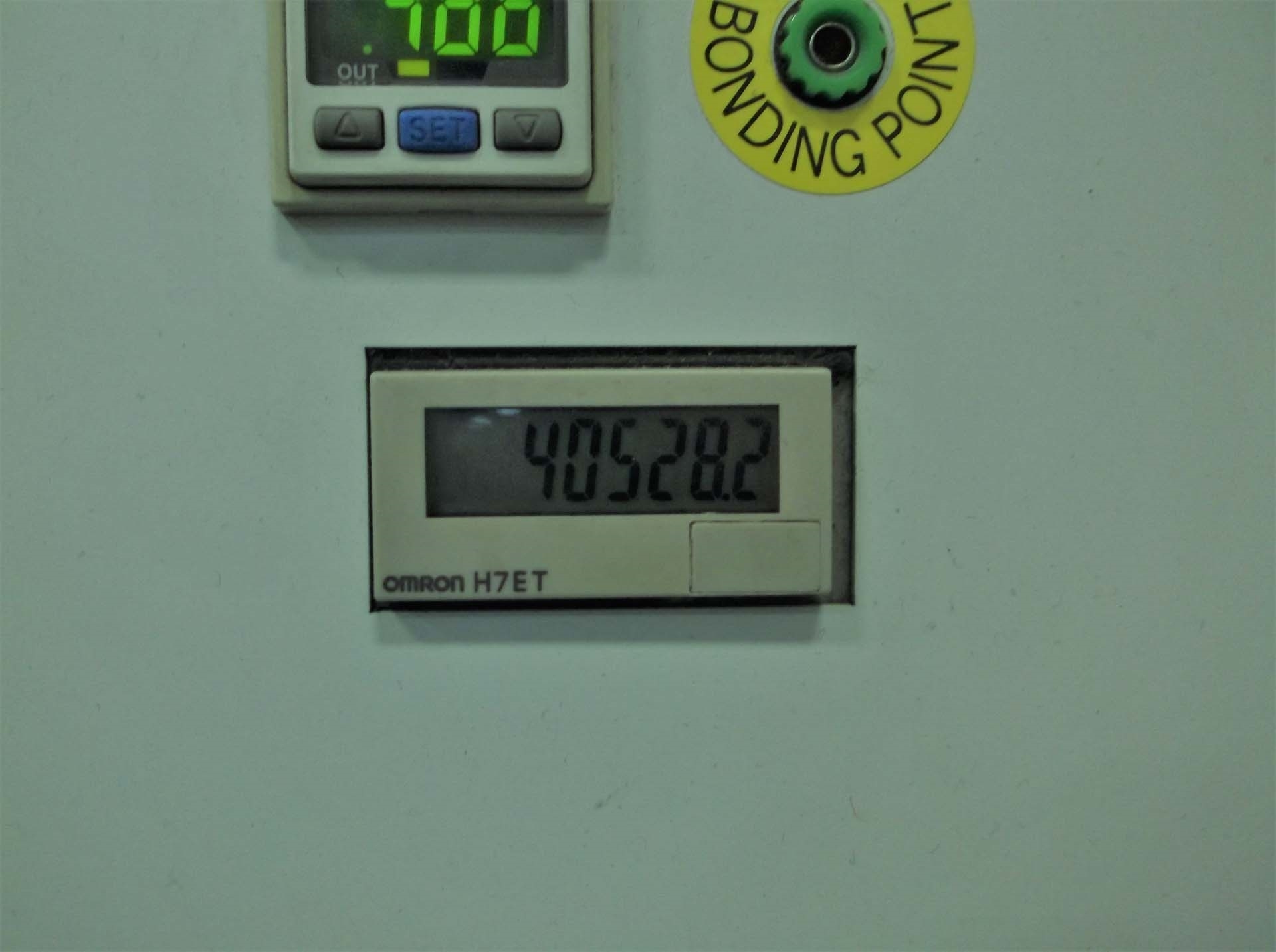

Hours: 40,528.2

Single lane conveyor

Feeder slots: 180 mm x 8 mm

Maximum PCB size: 508 mm x 356 mm

Placement heads:

(2) H12

H08

H04

Tray and stick feeders

Adhesive dispensing head

2006 vintage.

FUJI AIM is an automated, integrated and full-scale production line equipment introducing an innovative "Advanced Integration Method" (AIM), which allows for efficient and smooth throughout the entire SMT (Surface Mount Technology) board assembly process. It integrates all of the processes required for SMT assembly on a single line, from material transport to board assembly to finished product testing. The system offers three main components: FUJI AIM Robots, AIM Cells and FUJI AIM Stations. AIM Robot is an autonomous, self-learning robot customized for specific requirements. It works with the help of FUJI AIM Cells, which are automated stations with integrated functions such as feeders, presses and placement machines. These AIM Cells can be arranged freely in order to customize the unit to the requirements of each assembly without the need for complicated programming. Finally, FUJI AIM Stations are special fixture platforms designed to safely and precisely place components into the boards. AIM machine is highly efficient and versatile, allowing for a repetition rate of up to 40 boards per minute with uptimes exceeding 99%. The combination of FUJI AIM Robot, AIM Cells and FUJI AIM Stations ensures a smooth, efficient production line with a low defect rate. The repeatability and accuracy of AIM components also allow for high precision and repeatable processes, including insertion, component placement, solder quality control, board cleaning, board stacking, print control and surface mounting. Another great advantage of FUJI AIM, is its visualized control tool for manual operations, called "Manual Operator Interface" (MOI). This asset allows for continuous operation of the line even when manual operations are needed, while giving an indicator of exactly which steps have been completed. It also clearly displays messages regarding line performance information, which can be monitored in real time in order to quickly identify and intervene on any production issues. In conclusion, AIM model is a comprehensive full-scale solution for efficient and smooth SMT assembly production. Because of its high degree of repeatability and accuracy, as well as the integration of process-varying machines, the equipment can be tailored to the needs of each individual board assembly. Finally, the control system for manual operations simplifies line operations, making FUJI AIM an ideal choice for any board assembly and manufacturing need.

There are no reviews yet