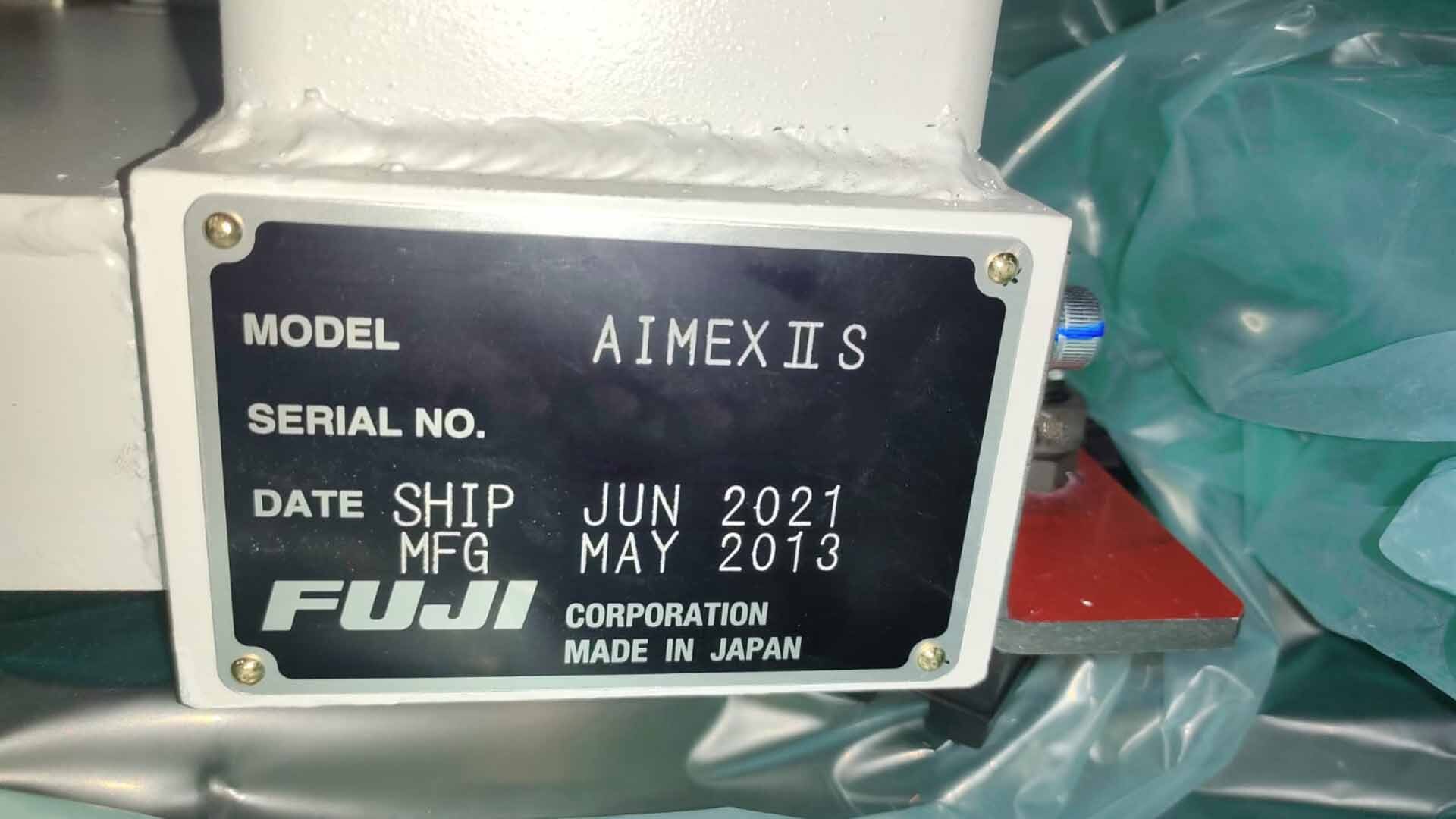

Used FUJI AIMEX IIS #9393564 for sale

URL successfully copied!

Tap to zoom

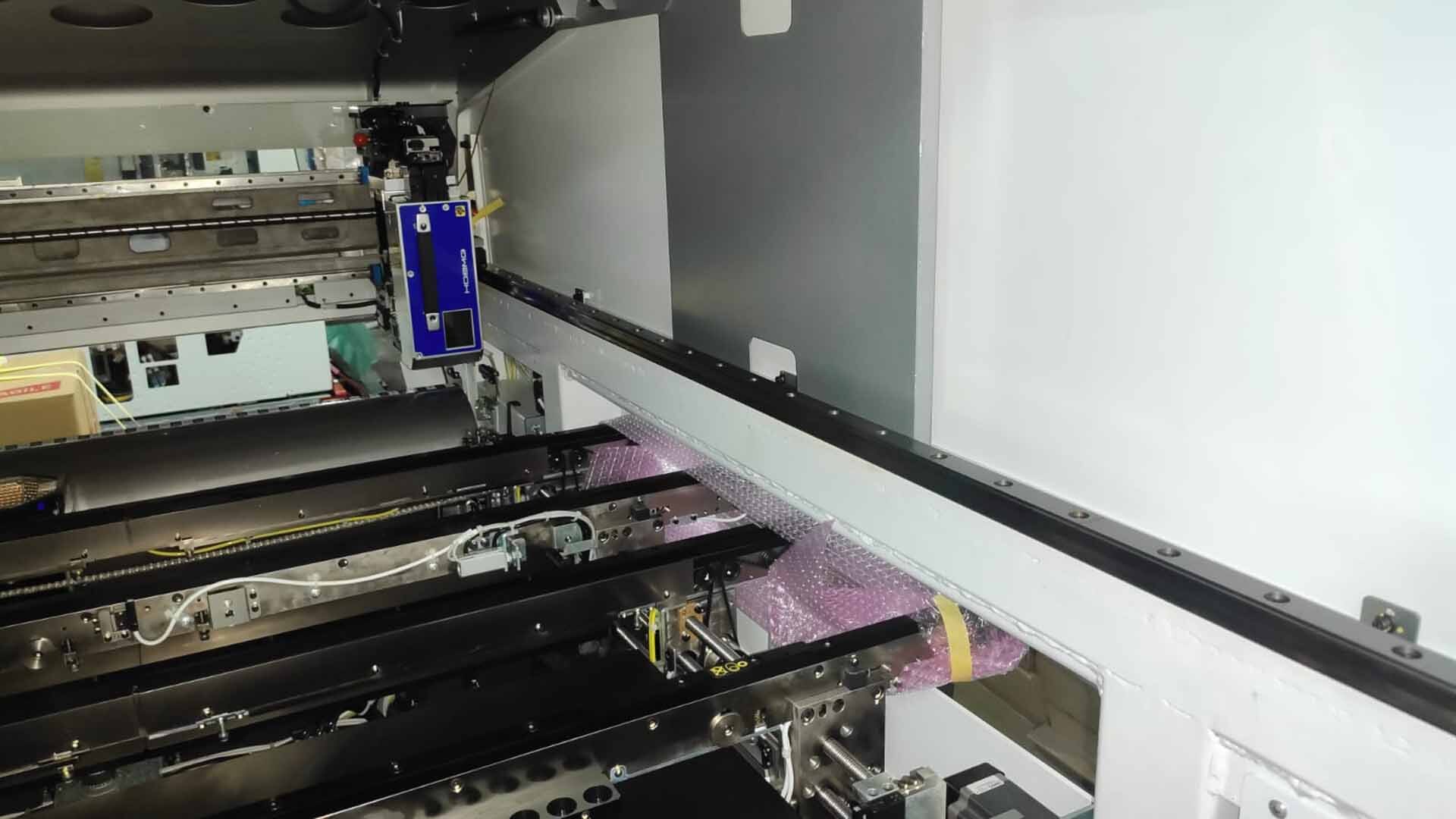

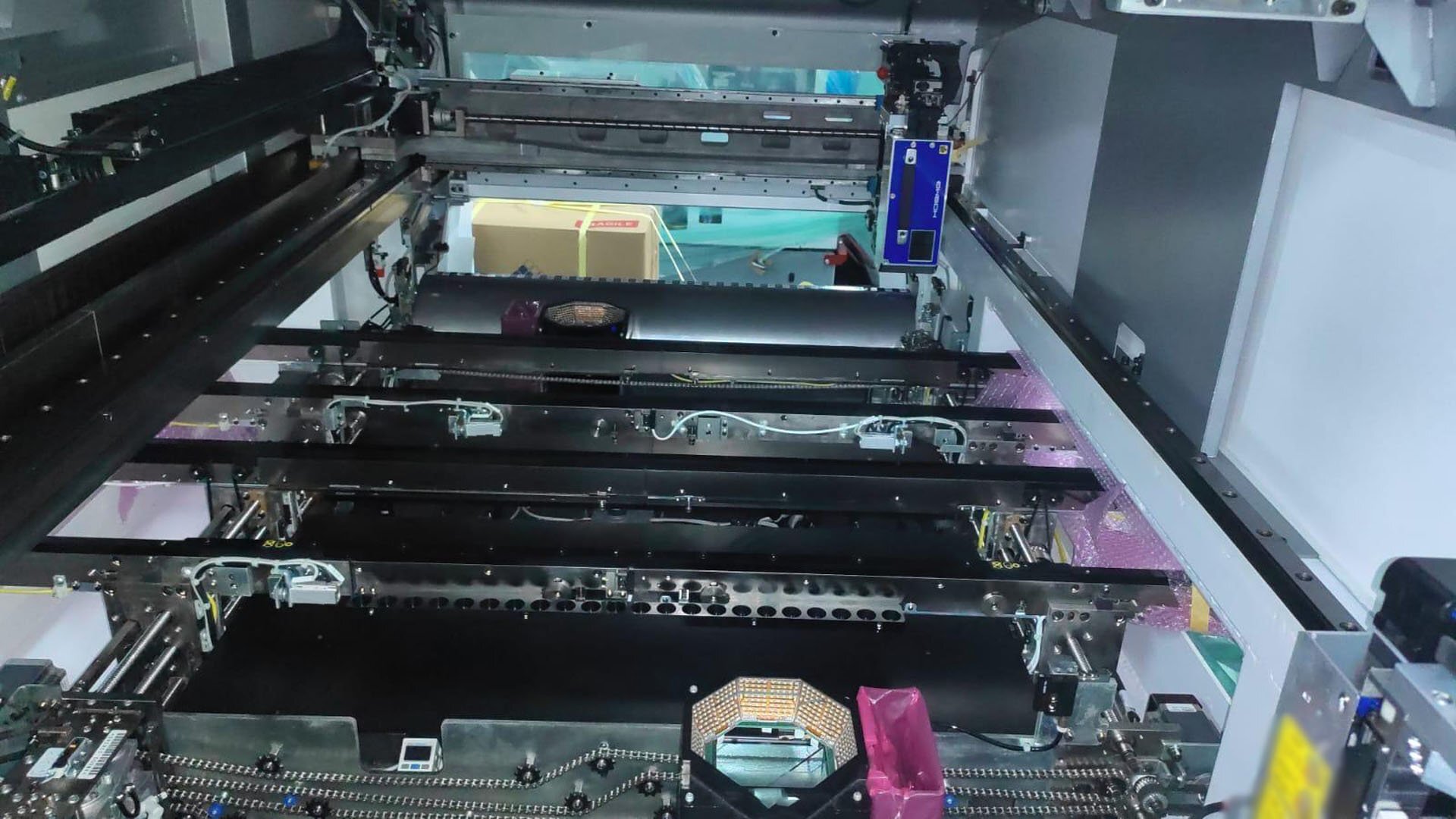

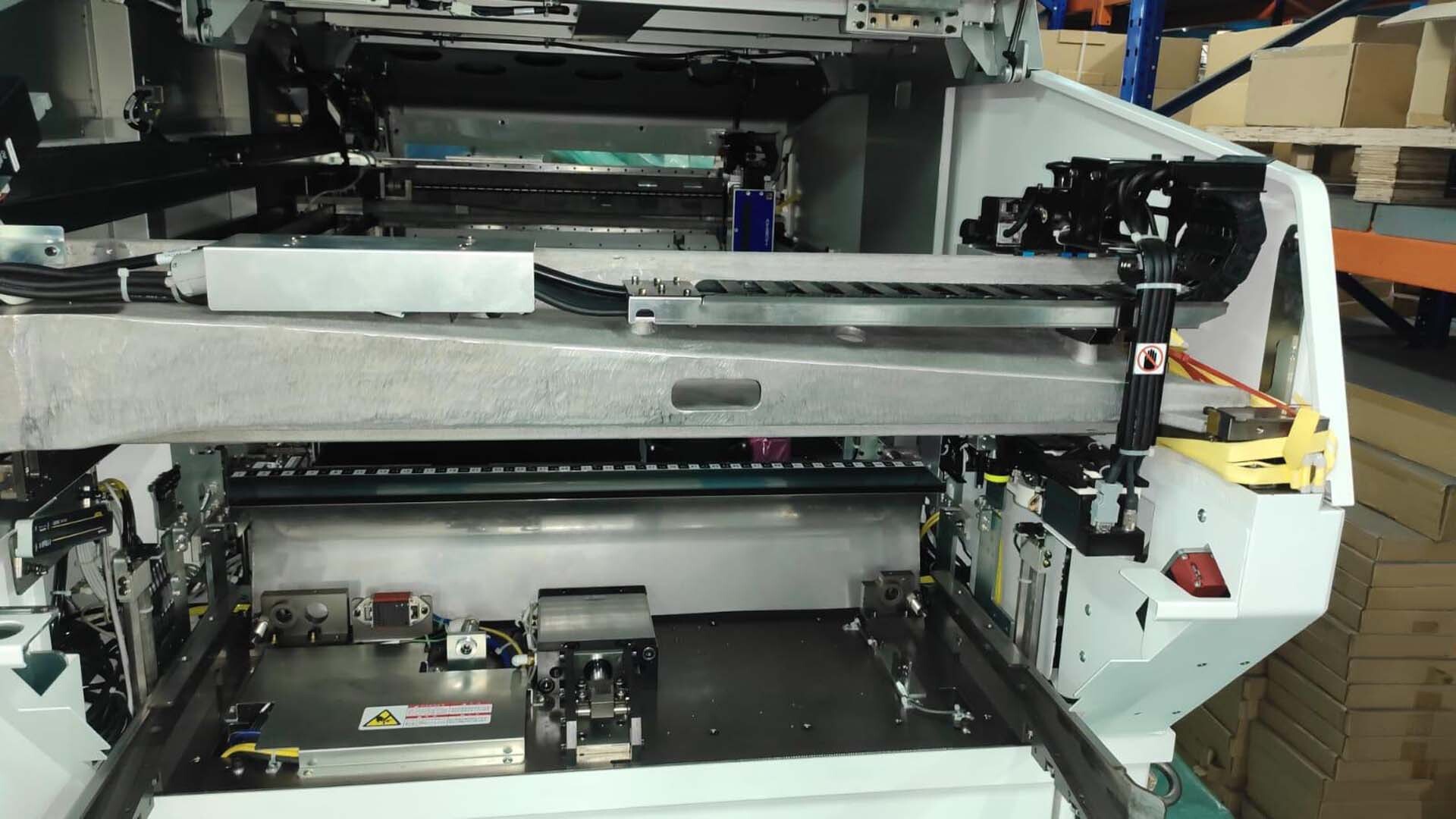

FUJI AIMEX IIS is an advanced pc board assembly and manufacturing equipment consisting of an automated pick and place machine and a conveyor system. It can be configured with a variety of equipment and software combinations. It has flexible placement designs to accommodate SMD and thru-hole components and a high accuracy rate of placing tight pitch components. Its vision unit is based on a 3D camera that provides automated recognition of parts and board positioning. Its automatic PC board loader and unloader are designed to minimize cycle time and reduce humidity impact. The multi-pin hole checker is a fully automated machine that can check the pin holes of ICs and other components and can identify any missing or blocked holes with accuracy. Its 3D AOI enables 100% of surface mounted components to be monitored for assembly errors and yields a higher quality of production. The tool is capable of assembly and routing for power transformers and lead wire adapters. It also has a function for setting up board and inspection where any trained operators can set up boards to be processed and inspected. As a safety measure, multiple sensors are built into the machine to provide a higher level of safety to the operators. AIMEX IIS is compatible with virtually any type of software and allows the user to configure different levels of security. The asset features a CAD and CAM interface which enables users to create geometrically complex designs. It has an automatic test pattern generation and automatic wiring feature which simplifies the process of connecting and testing components. The high speed cycle time makes it suitable for mass production. This model is also able to provide diagnostic information to assist in troubleshooting problems and data analysis. The Fujifilm FUJI AIMEX IIS is ideal for assembly and manufacture of highly reliable and technologically advanced pc boards. It offers a wide range of advantages and products that can be integrated into factories, manufacturing lines and test systems. Its functionality, accuracy and compatibility, makes it a highly appreciated equipment for PCB production.

There are no reviews yet