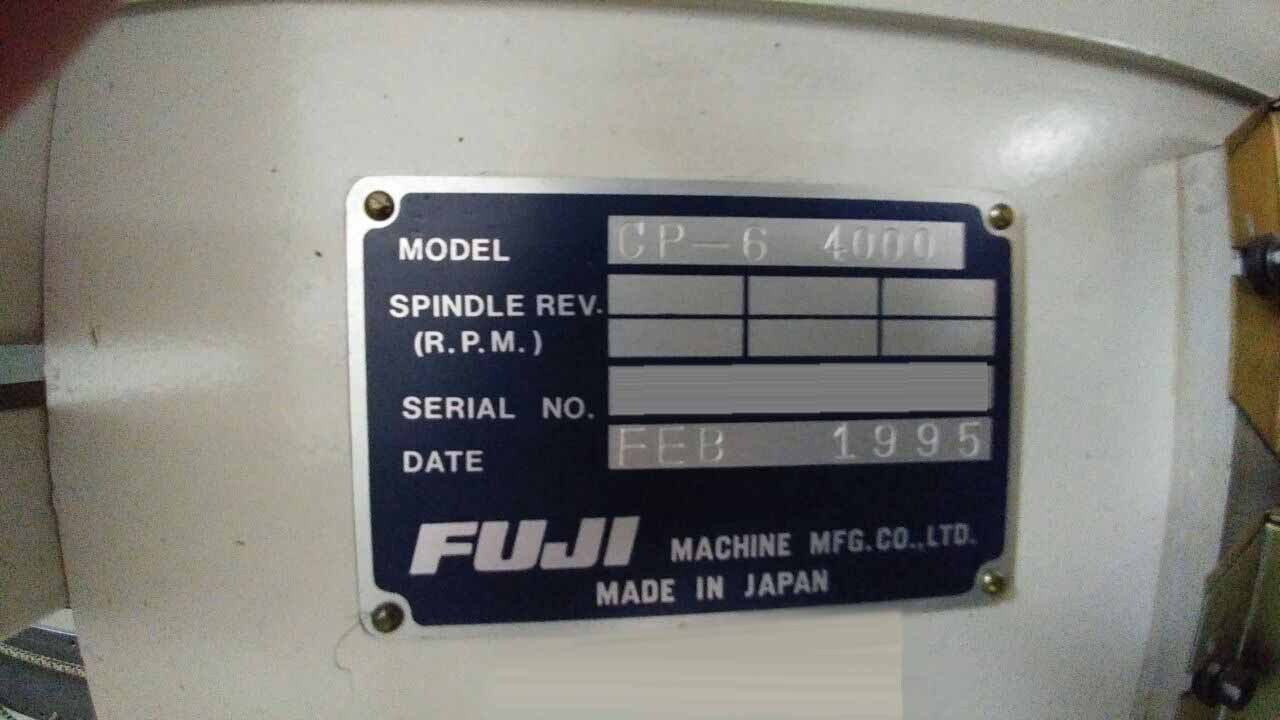

Used FUJI CP 6 #9172600 for sale

URL successfully copied!

Tap to zoom

FUJI CP 6 is a powerful PC Board Assembly and Manufacturing equipment designed to streamline the automated assembly and manufacturing process. It is a multifunctional, flexible system that can be used in many industries and to produce multiple types of PC Boards. FUJI CP6 is composed of several pieces of machinery, including a main board assembly machine, Pick & Place machine, Wave Solder machine, and Quality Control Unit. Each component of the machine is designed to interface with the other to create an efficient, end-to-end manufacturing solution. The Main Board Assembly machine is responsible for all of the electrical contact points of the PC Boards. It has a vacuum based head that allows for low-power soldering of all of the components on a PC Board. It is also versatile enough to handle both through-hole and surface-mount components. The Pick & Place machine is designed to identify and accurately place components onto a PC Board. It is extremely accurate and can handle a variety of component sizes. The Wave Solder machine uses three interchangeable solder pots, allowing for an efficient and high-quality soldering process. Finally, the quality control tool is able to detect faint electrical signatures and analyze any defects that may have occurred during the manufacturing process. It is also able to provide statistical information about each board, such as yield rate, rework rate, and rate of defect occurrence. CP 6 is the ideal solution for any company looking for a high-quality, dependable, and cost-effective automated assembly and manufacturing asset. With its multiple components, it is able to provide an efficient and reliable performance that is backed by a comprehensive service package. It is the perfect model to help any company increase their productivity and efficiency while maintaining the quality of their products.

There are no reviews yet