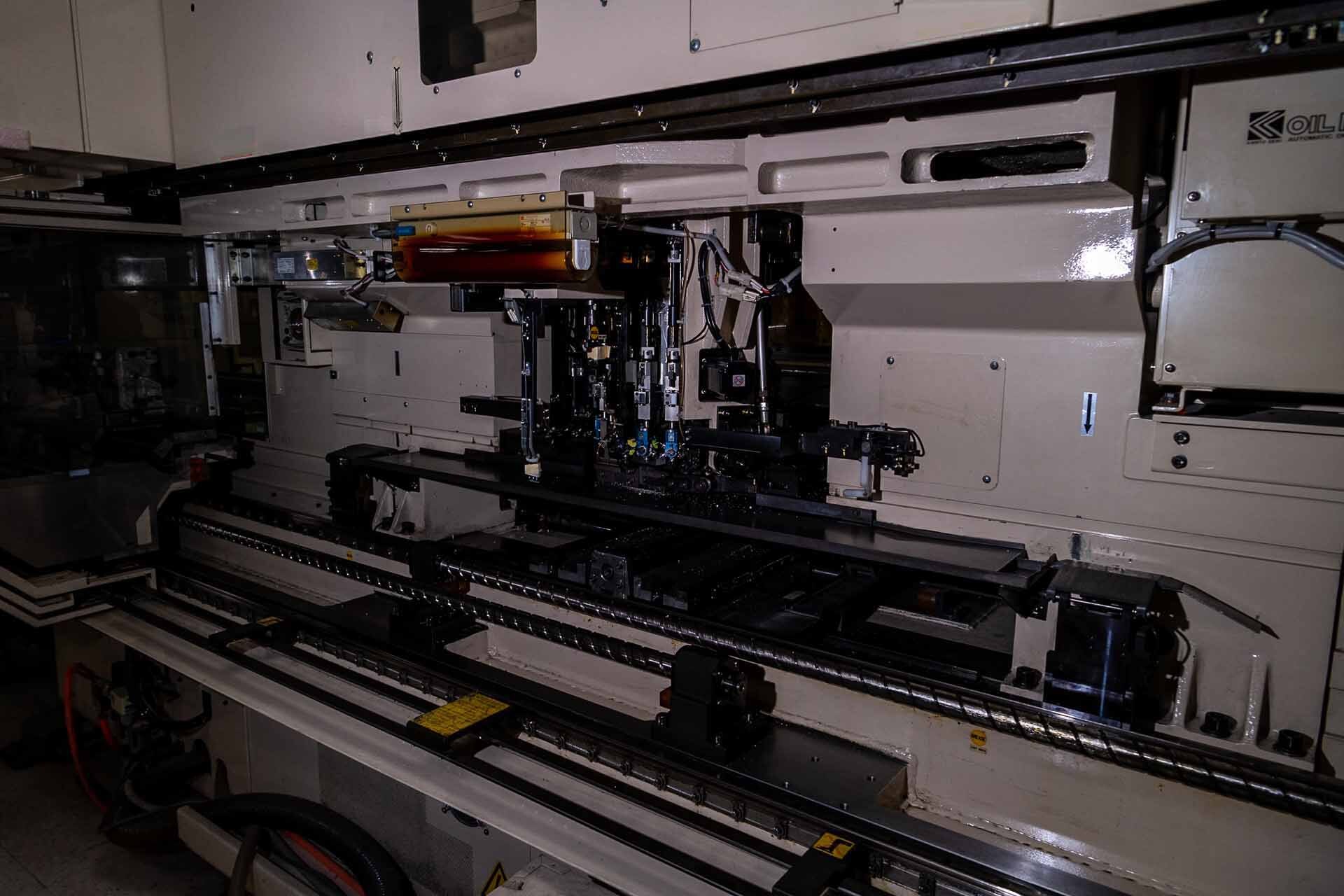

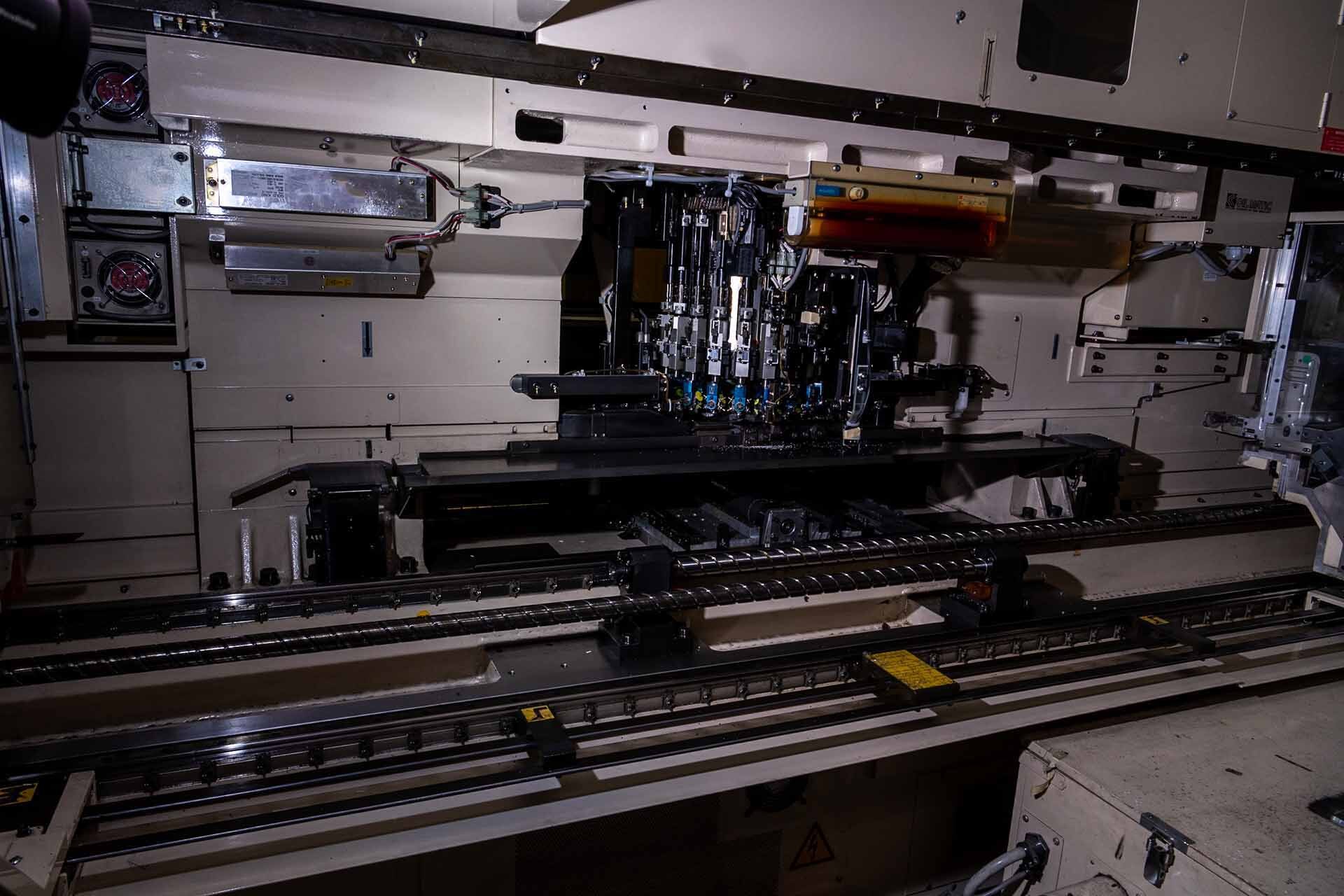

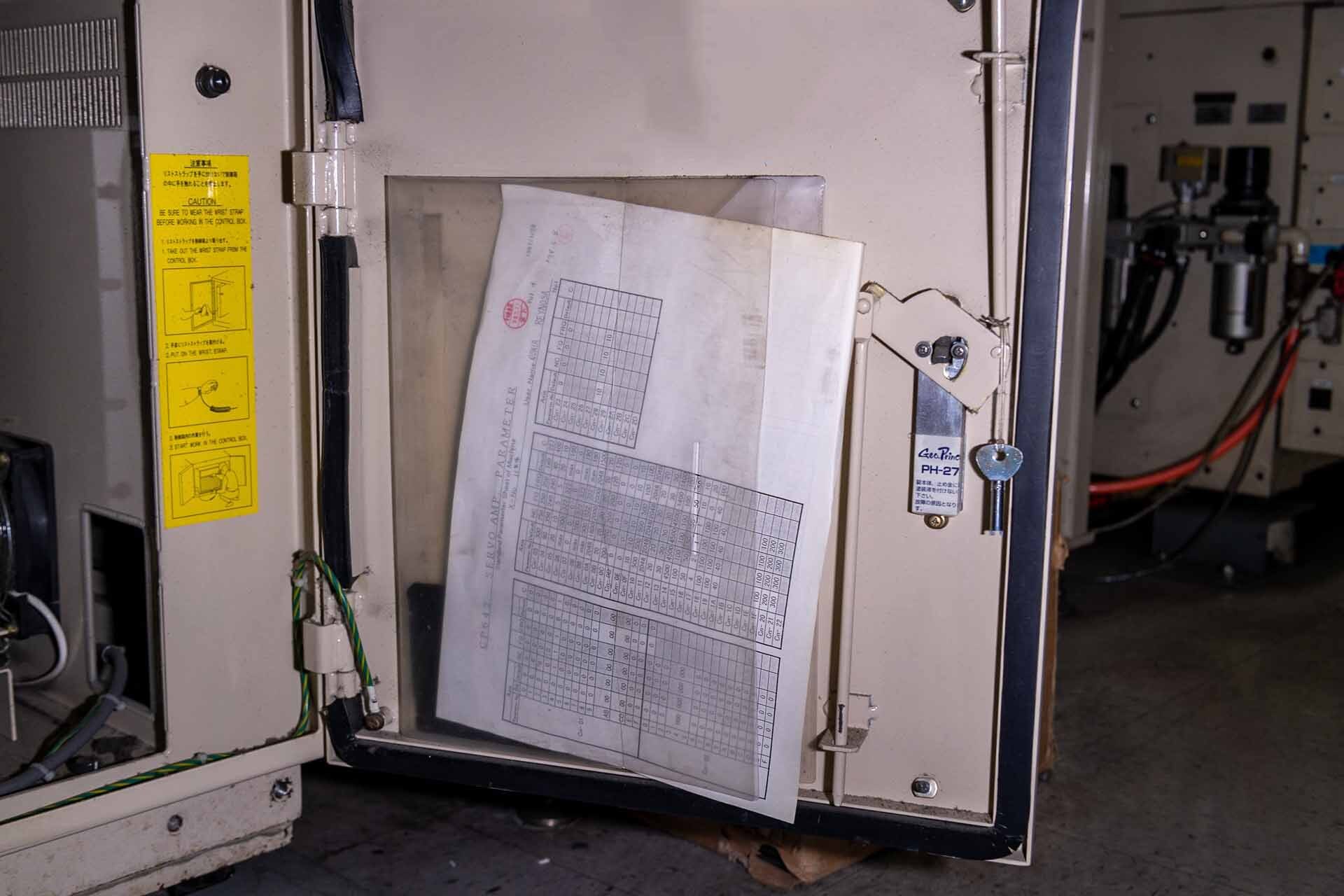

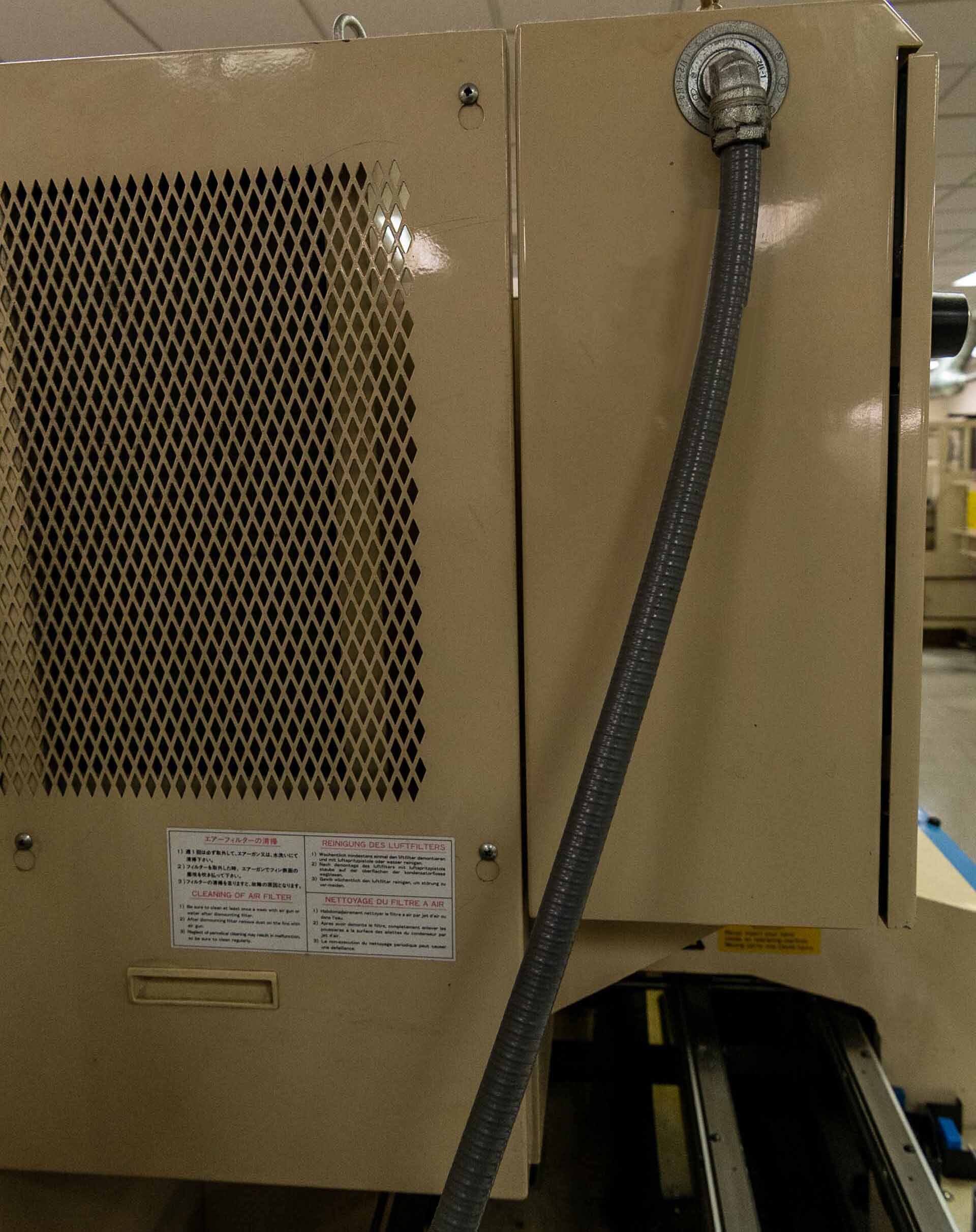

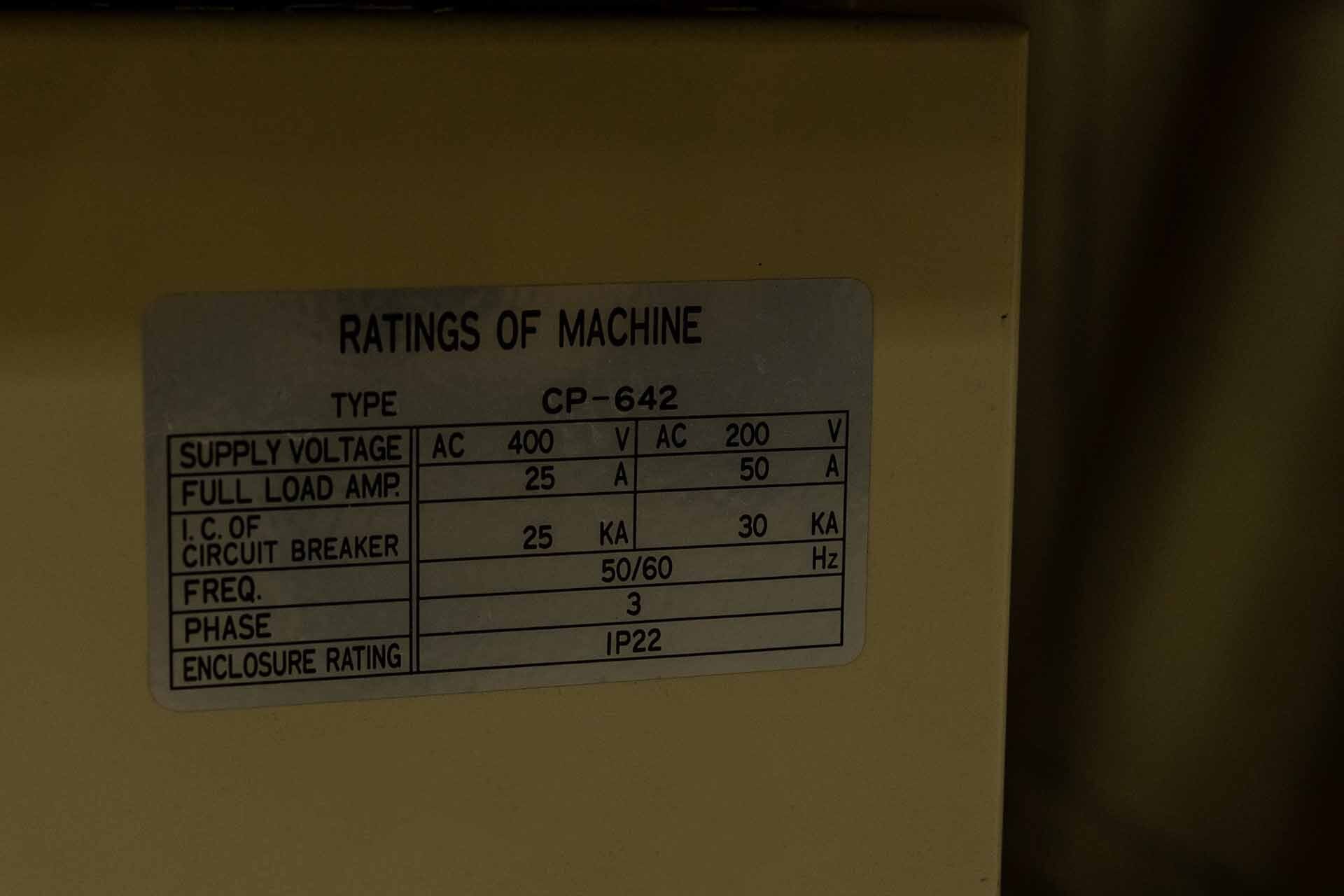

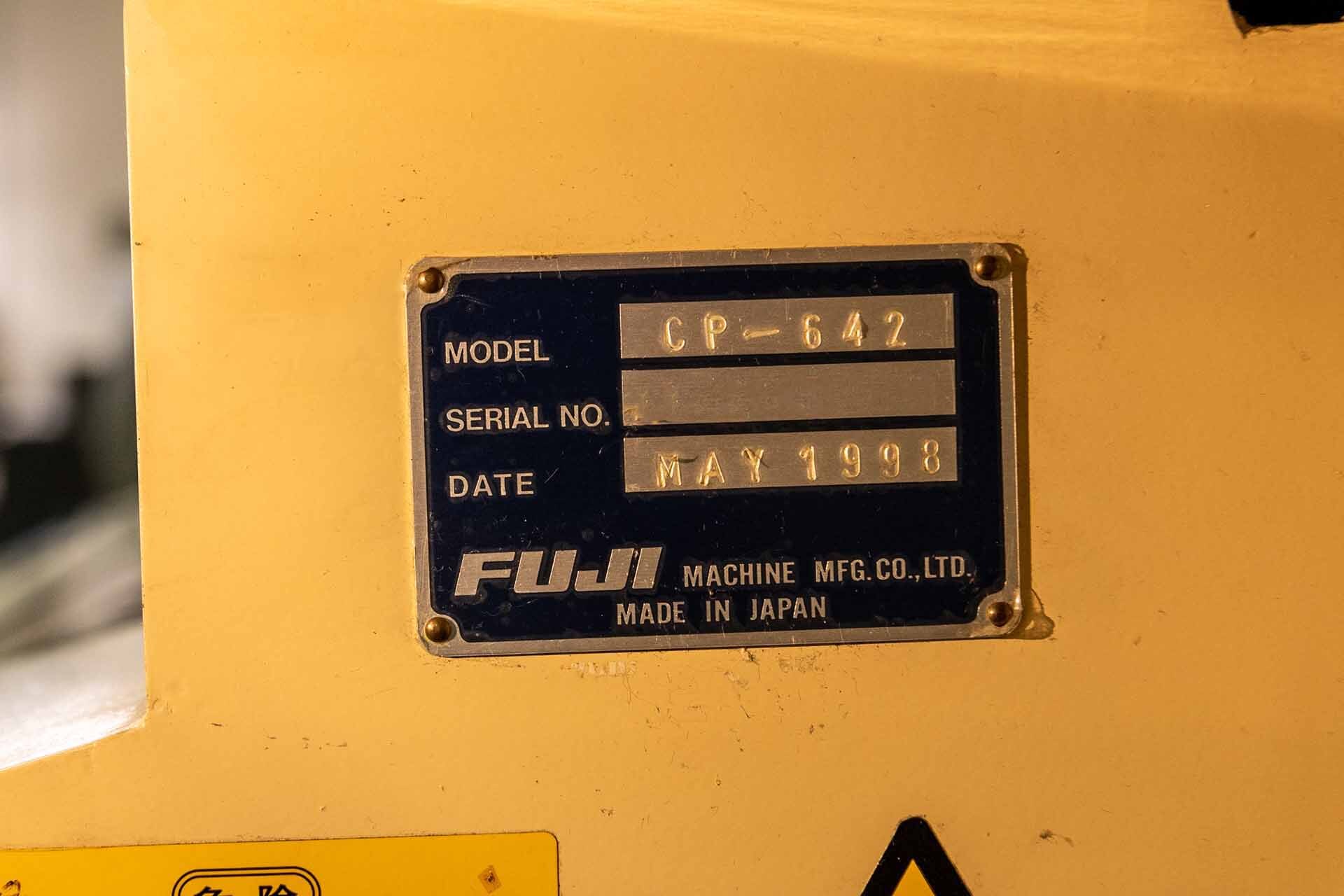

Used FUJI CP 642 #293616542 for sale

URL successfully copied!

Tap to zoom

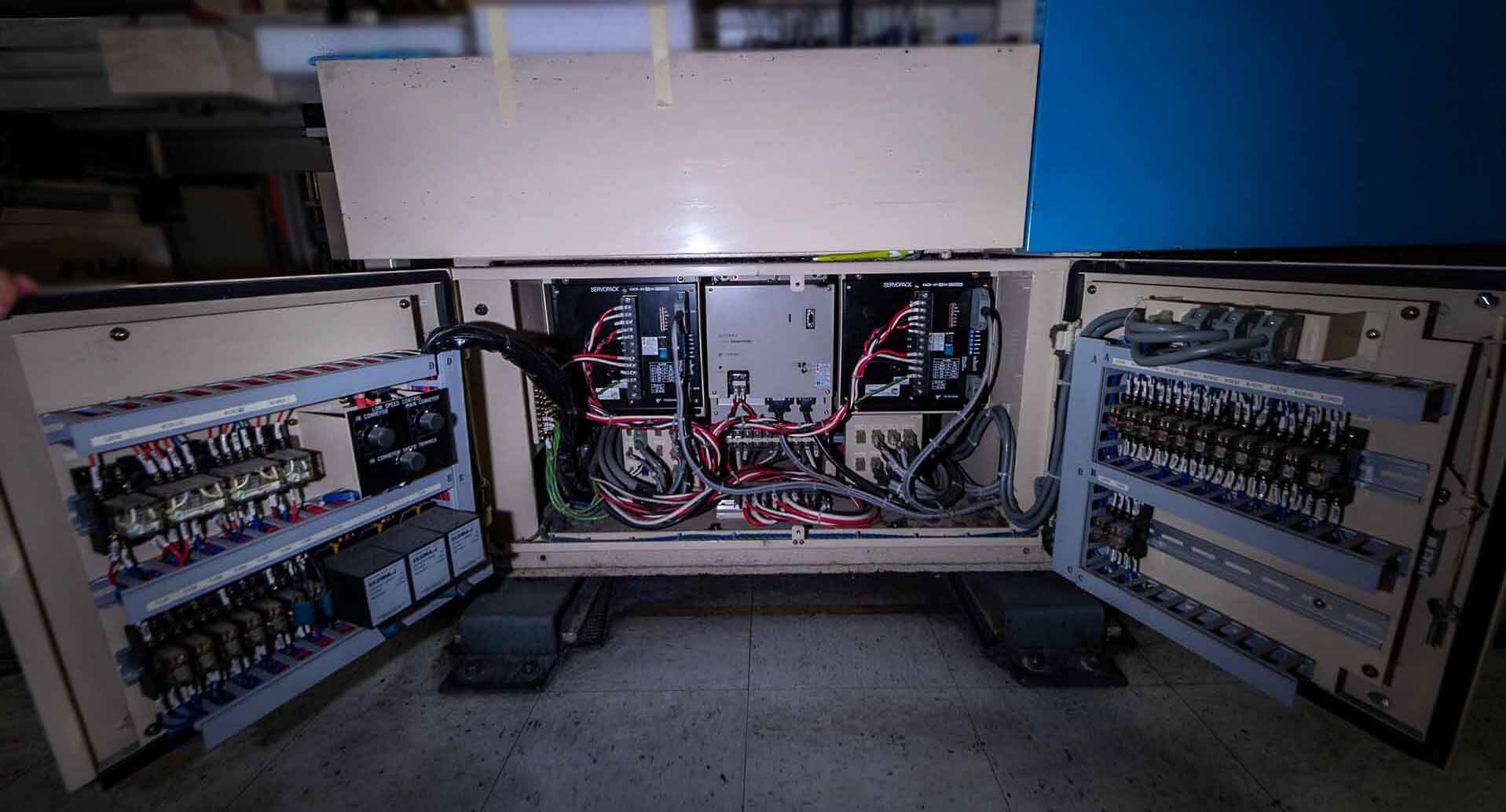

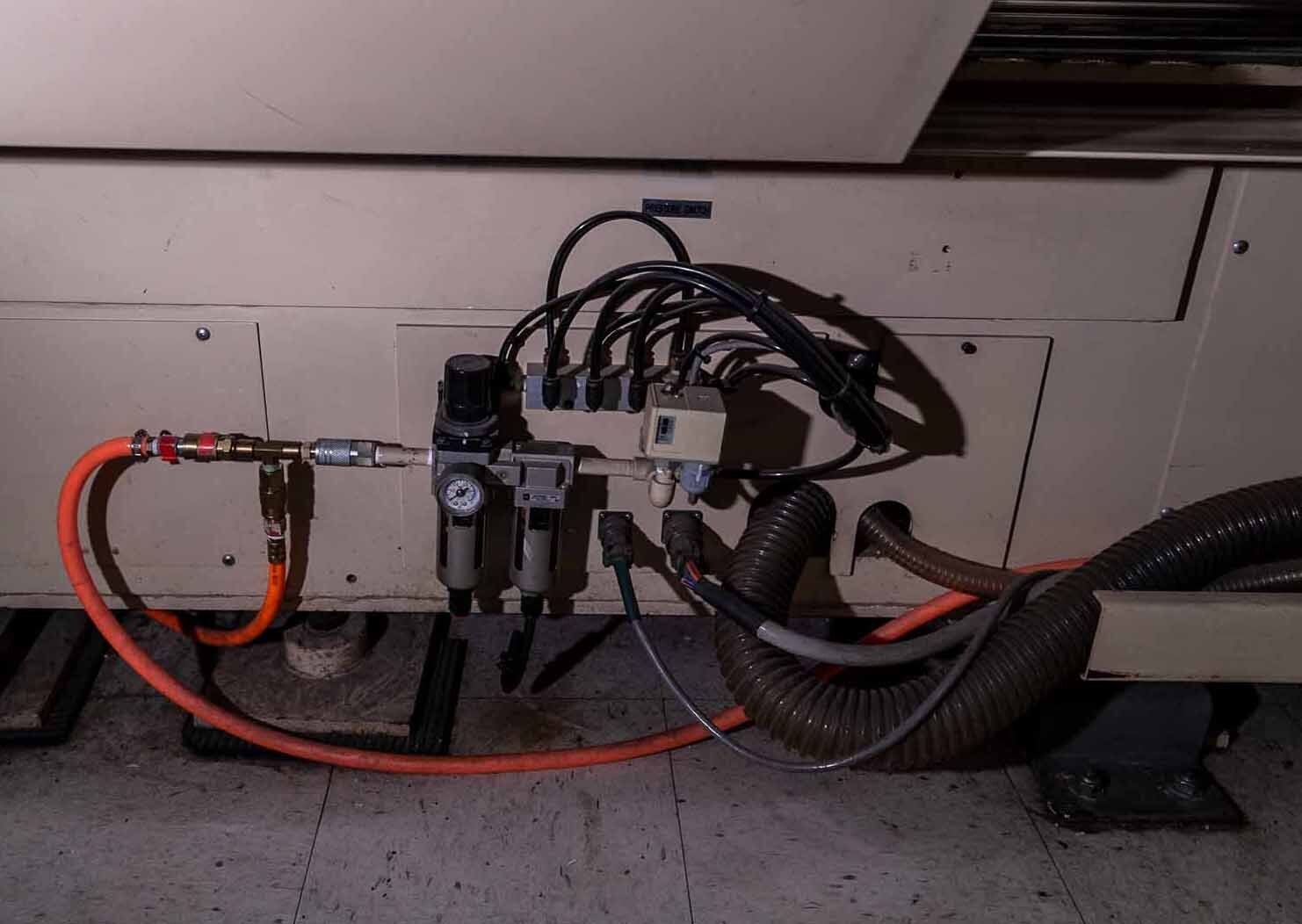

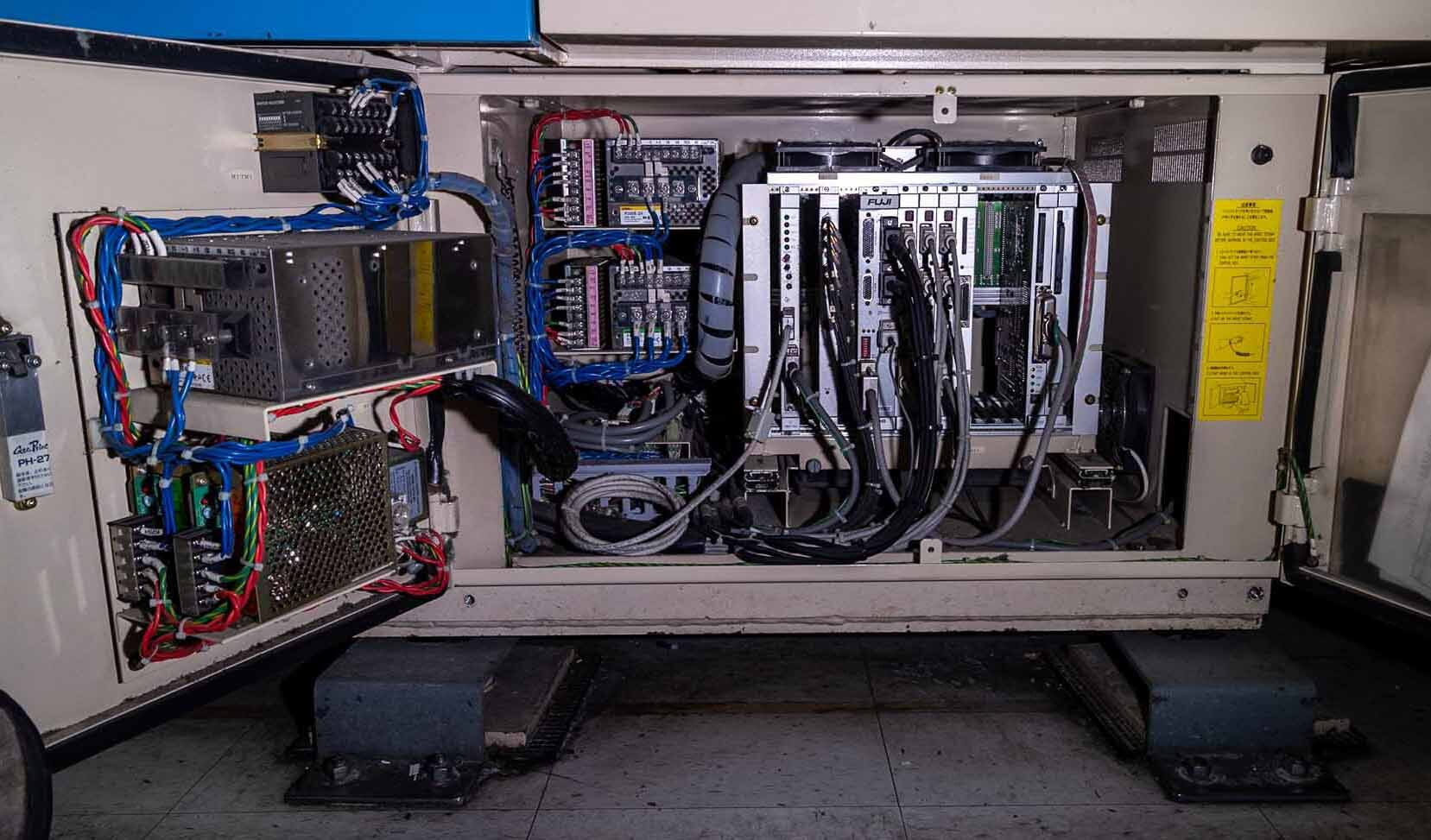

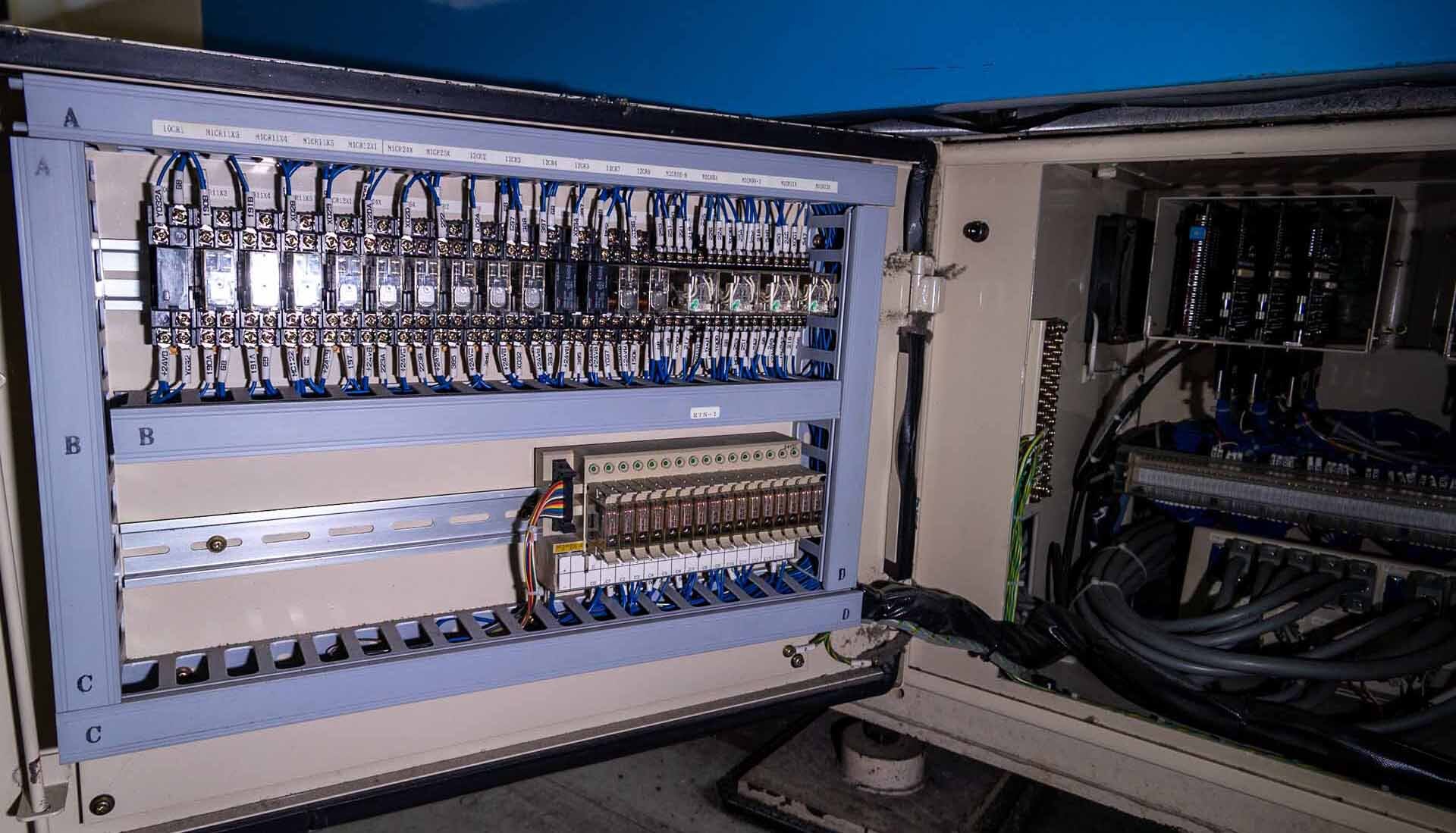

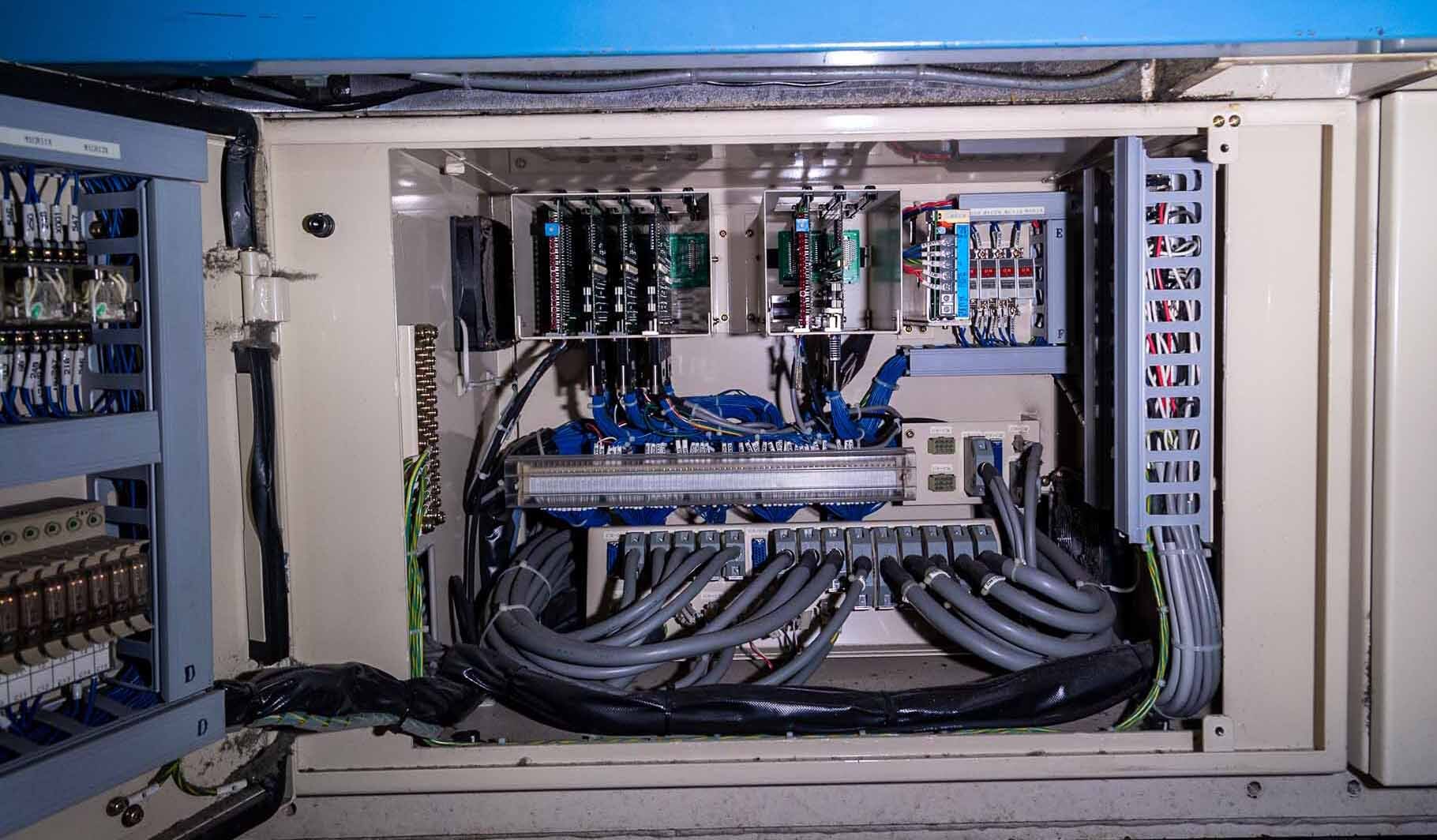

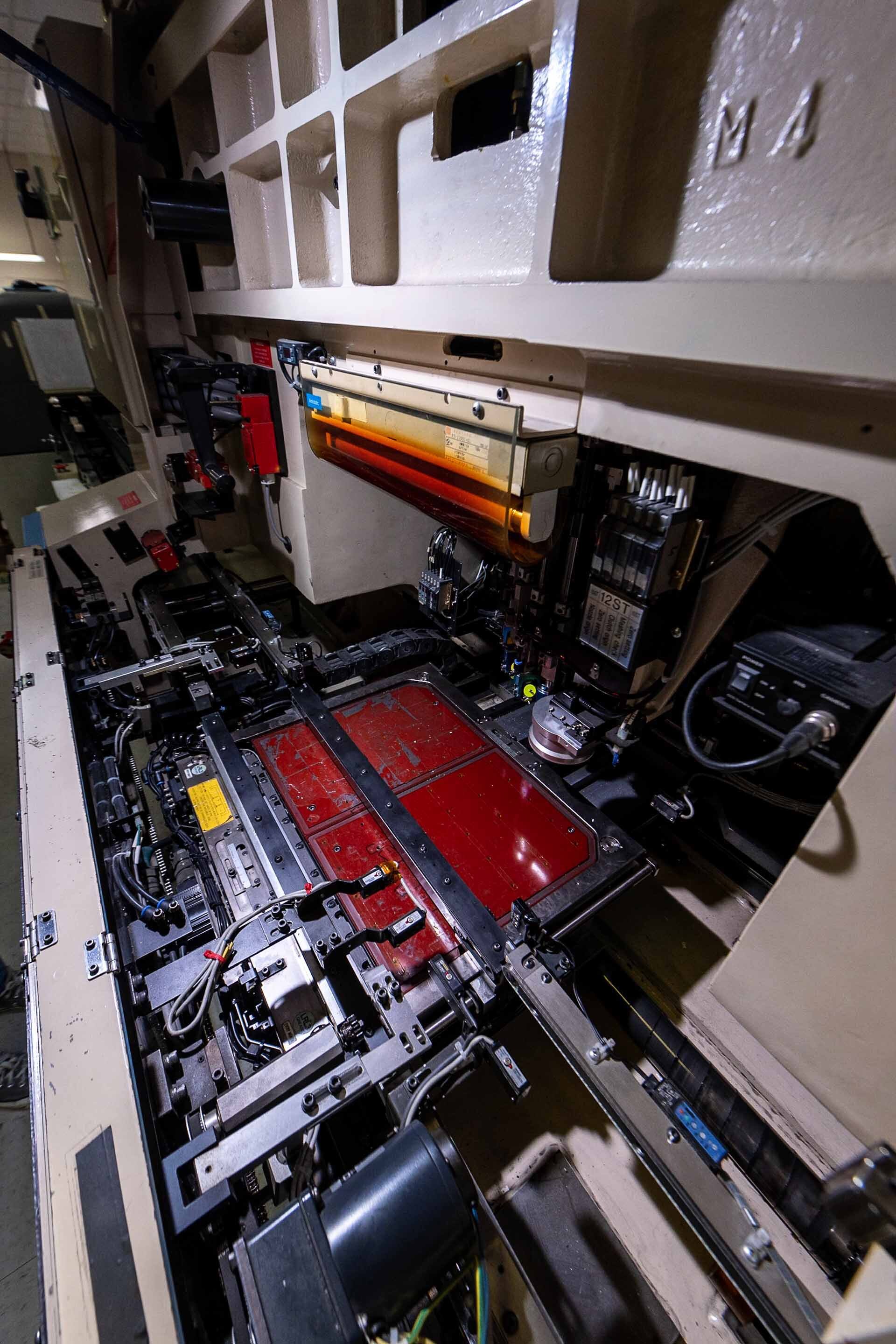

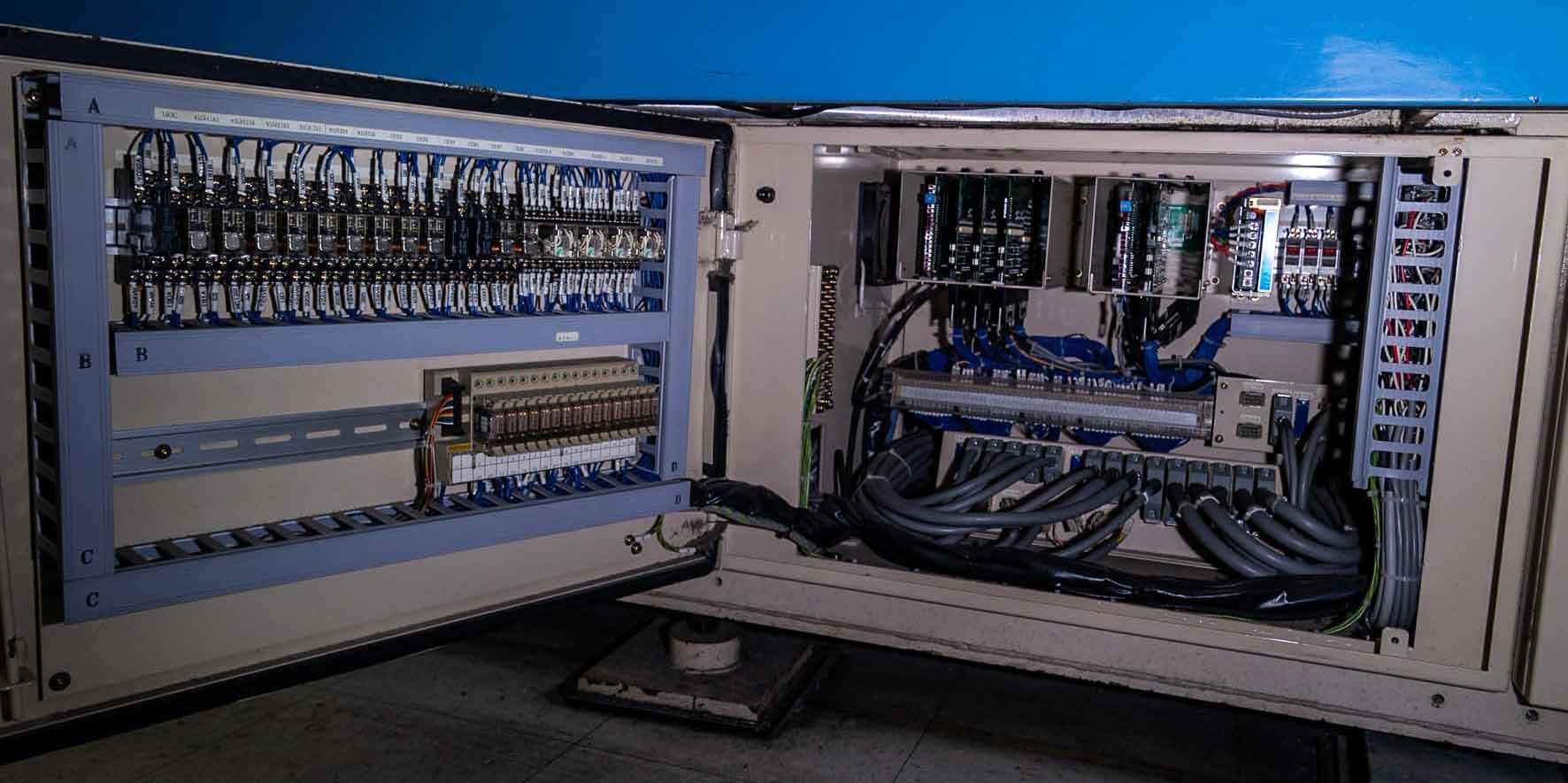

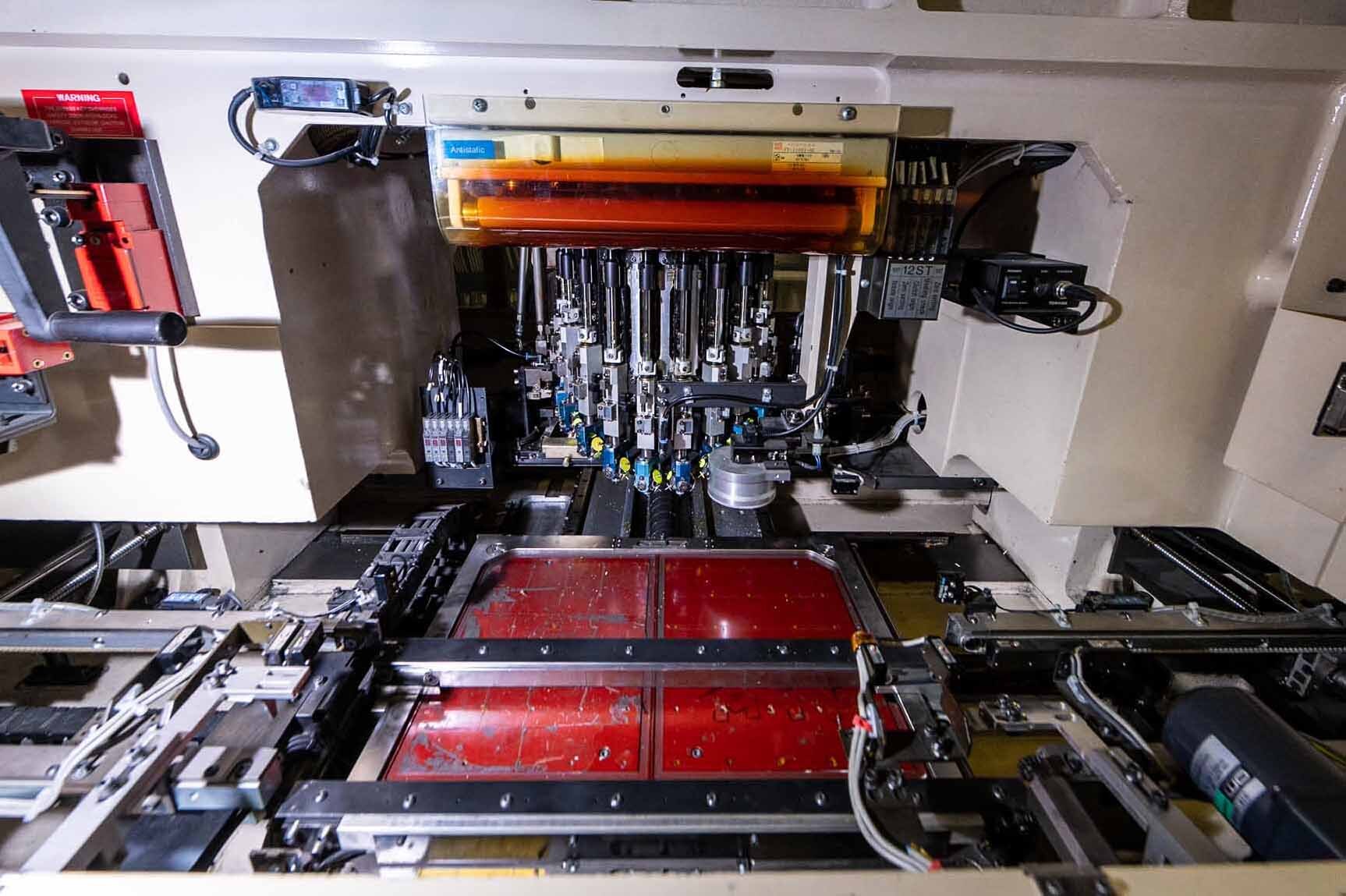

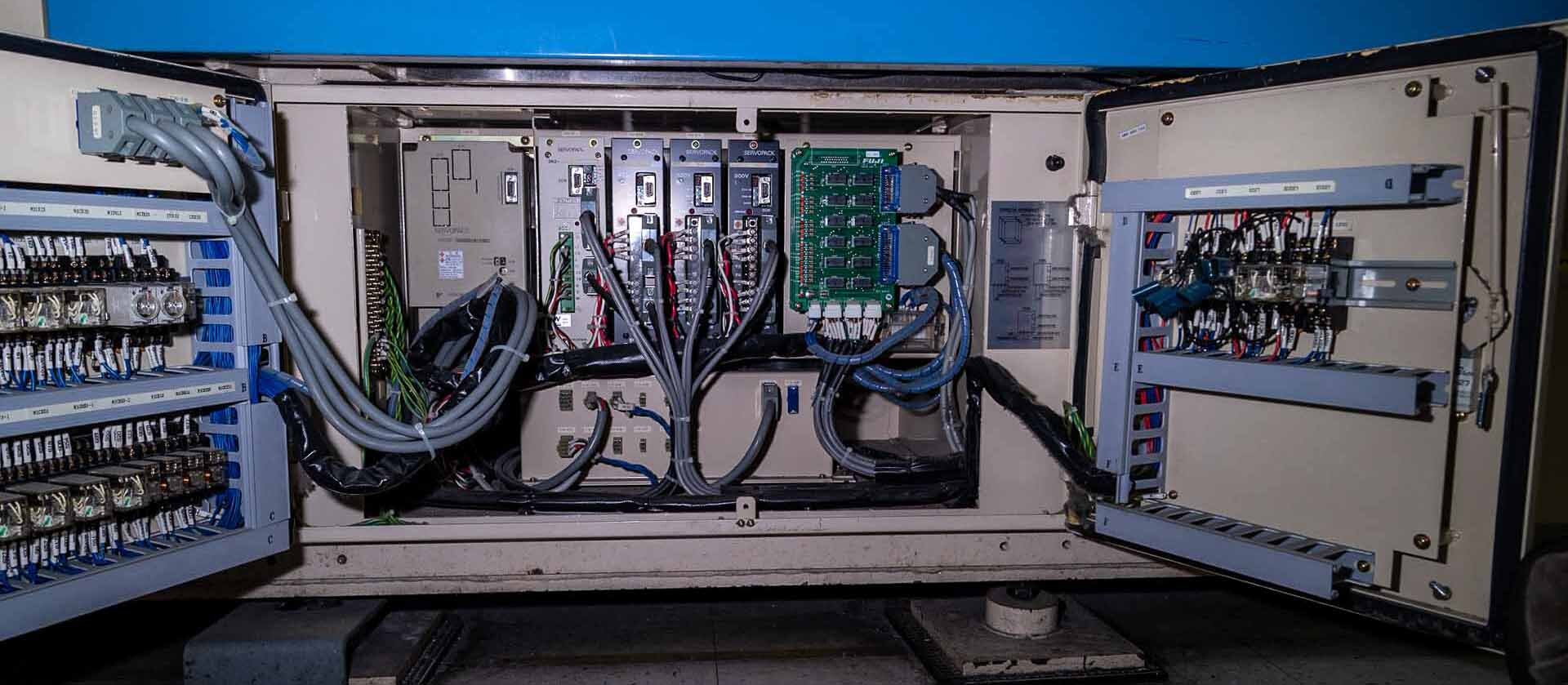

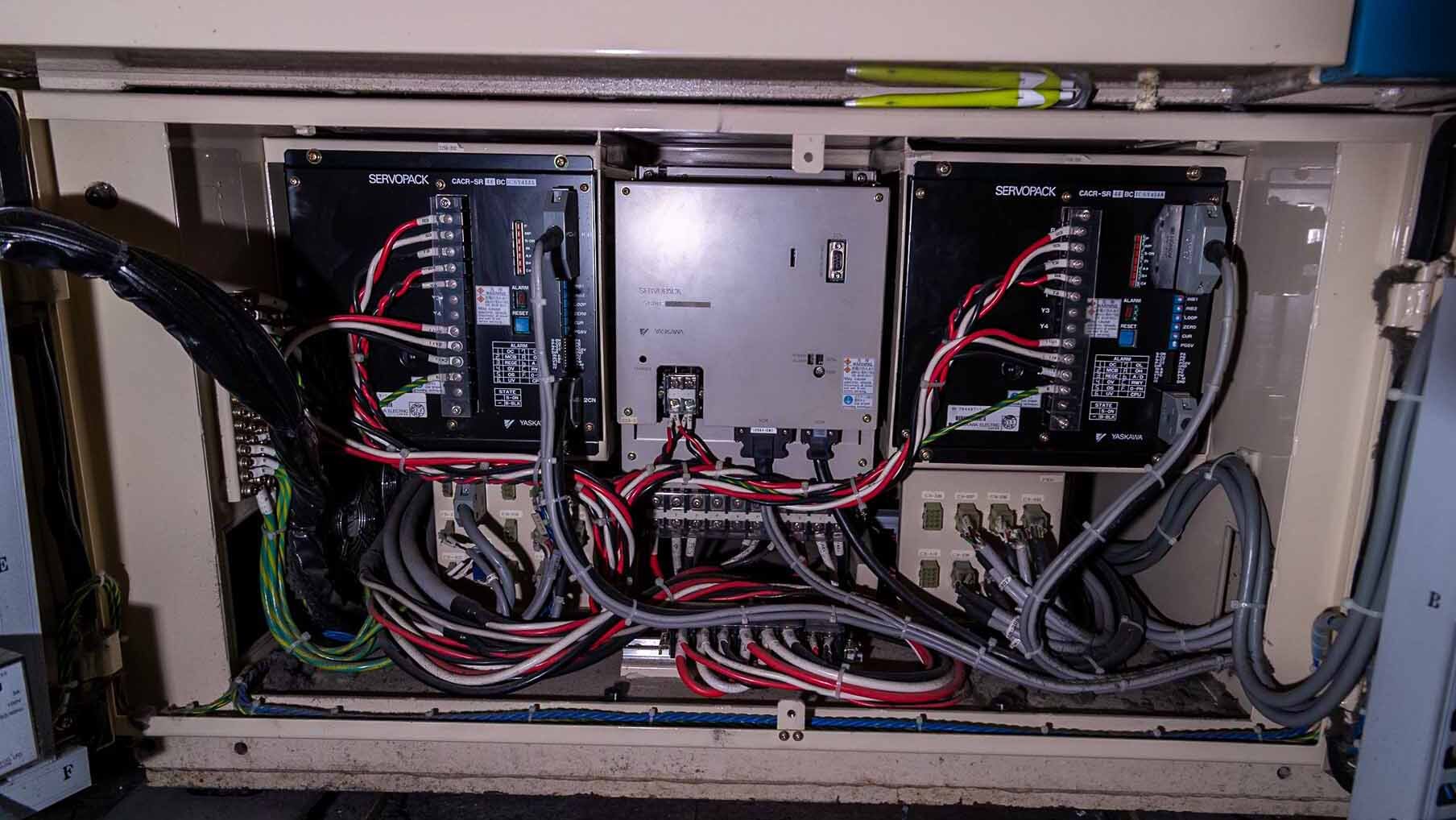

FUJI CP 642 is a high-performance pc board assembly and manufacturing equipment. This system is designed to handle all of the necessary steps in pc board assembly and manufacturing. It is fast, efficient, and capable of completing production runs quickly and with high accuracy. FUJI CP642 features a fast, precision-based process for high-quality assembly, including a fast pick-and-place head, support station, and debugging tools. The pick-and-place head is capable of quickly placing components onto the board accurately with a minimum amount of time. The support station provides a secure platform for components during the assembly process. The debugging tools allow for fast and convenient troubleshooting of the boards. CP-642 also features a powerful automatic vision inspection unit that helps identify problems during assembly. This machine is designed to detect any issues that may arise during the assembly process, so that any problems can be quickly identified and rectified. This tool also helps ensure that the produced pc board is of high quality and is able to meet end-customer requirements. CP642 also includes a fast solder-reflow module, allowing for quick and accurate solder reflow during the assembly process. This module is designed to provide reliable, clean and repeatable solder joints. It is also capable of producing high-quality boards that have superior electrical characteristics. The solder-reflow module also has the option of intelligent heating cycles, further reducing errors and improving accuracy. Finally, CP 6-42 includes powerful repair and rework capabilities that can quickly restore faulty components or boards. It also includes an automatic soldering-tip scanning asset, which helps identify faulty areas of the board and provide an automated solution to repair the problem. CP 642 is an excellent model for high-performance pc board assembly and manufacturing. Its fast, precise process enables boards to be produced quickly and accurately, while the intelligent vision equipment and repair/rework capabilities ensure that the end-product is able to meet customer requirements.

There are no reviews yet