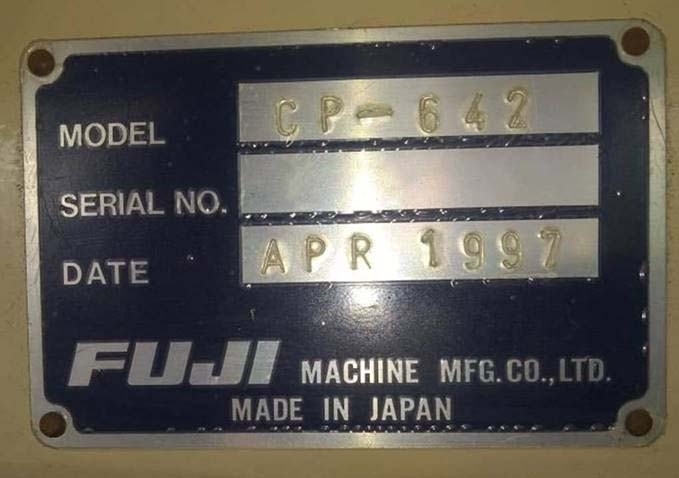

Used FUJI CP 642 #9286011 for sale

URL successfully copied!

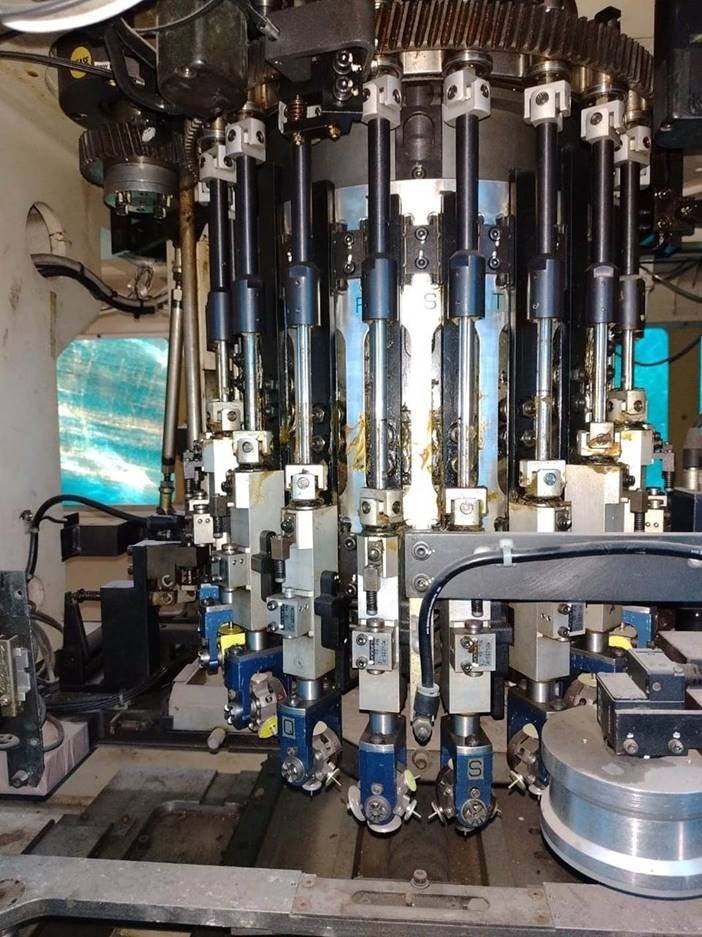

Tap to zoom

ID: 9286011

Vintage: 1997

Chip shooter

(20) 8x2 Feeders

(20) 8x4 Feeders

1997 vintage.

FUJI CP 642 is a fully automated PC board assembly and manufacturing equipment from FUJI SMT in Japan. This system is designed to reduce production time and cost while increasing productivity and quality. It offers a comprehensive range of features including high speed processing, automated defect detection and analysis, and automatic material handling. FUJI CP642 unit has been designed for high-speed processing of up to 4500 component placements per hour and offers impressive performance levels. Unique features such as automatic tool setup and handling of odd and irregular shaped boards enable a greatly reduced production time. The advanced machine vision technology used in CP-642 automatically detects and rejects defective components which minimises rejects and recalls. CP 642 has a modular design which enables a range of unique and customisable production lines. This makes it an ideal solution for a variety of manufacturing processes such as component placement, reflow soldering, wire bonding, SMT, IC, or flip chip assembly. The machine is also designed to seamlessly integrate with additional machines and automation systems. CP642 includes an array of advanced tools and equipment that help streamline and simplify assembly operations. For instance, CP 6-42 includes advanced software tools for programming and machine setup, Camera Over-Gripper (COG) for advanced part presetting, Component Monitoring Tool (CMS) for quick board inspection and high-precision placement, and Stepper Asset (SS) for controlling movement, operation and accuracy. Additionally, the device features a Pick-Up Head (PUH) with eight precision pick-up needles for automated material handling allowing for greater flexibility. The model is compact, modular, and highly adaptable making it suitable for batch production and high-volume throughput. It also includes a wide range of additional features such as automatic pallet change-overs, quick changeover capabilities for different processes, a series of accurate vision cameras, and the ability to use up to four placement heads. FUJI CP-642 is designed to provide complete control of a wide range of assembly environments including high mix, low volume and high volume. Its robust design ensures reliable and accurate operation over extended periods resulting in greater accuracy and quality control. With its high-speed, efficient processing, and automated defect detection and analysis, FUJI CP 6-42 from FUJI SMT can be used to improve overall productivity and cost-efficiency.

There are no reviews yet