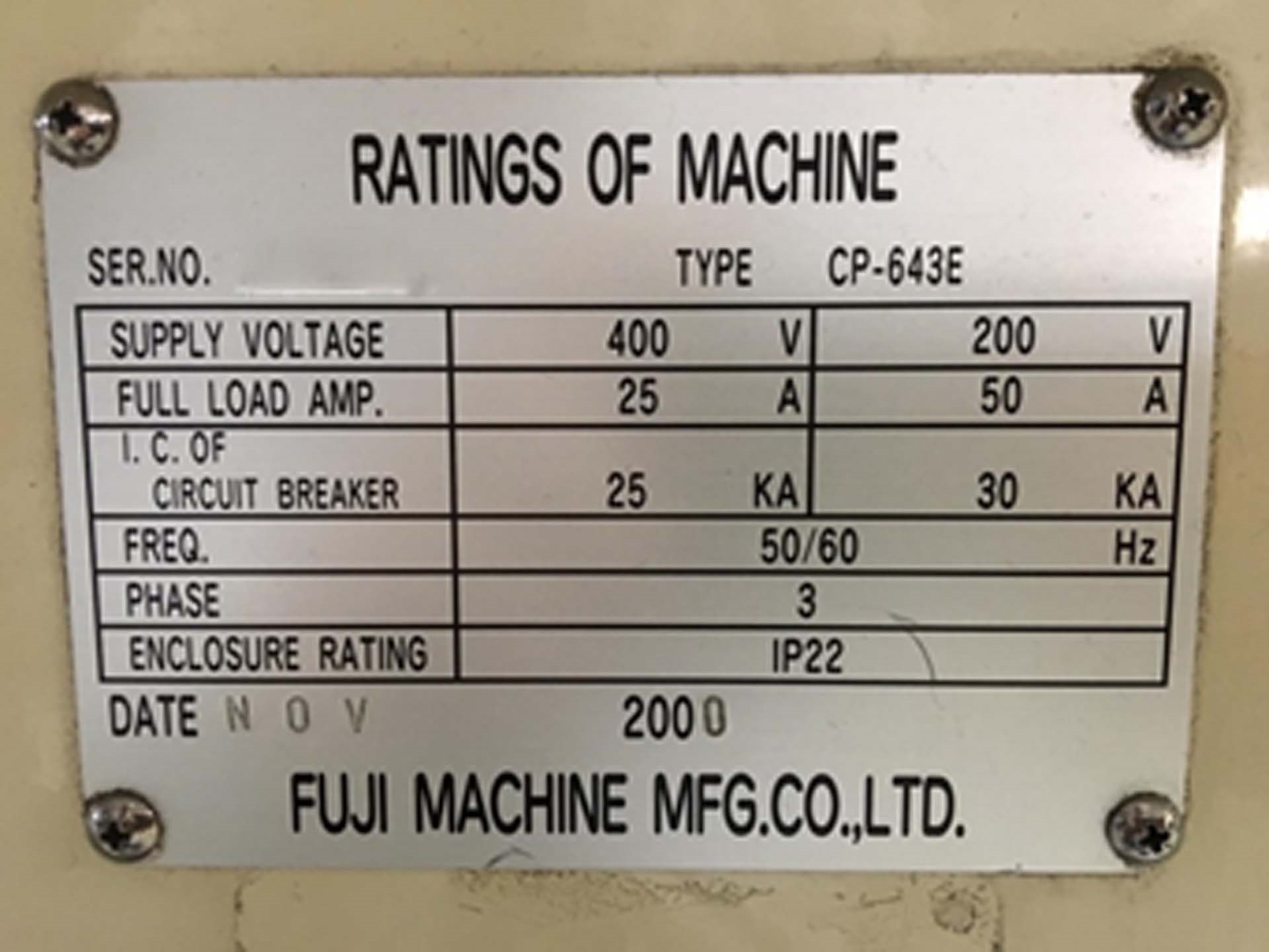

Used FUJI CP 643 #9240263 for sale

URL successfully copied!

Tap to zoom

FUJI CP 643 is a state-of-the-art PC board assembly and manufacturing equipment. The system features automated SMT line processes, cutting-edge image inspection technology, and a programmable robotic arm that aids in efficient and accurate assembly of printed circuit boards. FUJI CP643 features FUJI latest AutoRCP (Auto Robot Control Panel) for easy programming of the robotic arm, and integrated Parts Delivered Unit (PDS), which allows suppliers to deliver parts directly to the assembly lines. The integrated laser cut machine is designed to reduce the time needed for component placement. The Solder Pallet Exchange tool ensures that the soldering temperature and joint strength are maintained throughout the entire assembly process. The solder pallet is equipped with a temperature control asset, allowing it to accurately adjust the temperature for optimal soldering performance. The machine's mounted camera model uses image inspection technology to check the positioning of components, while the fiducial mark recognition equipment can recognize positions with an accuracy rate of 0.1mm. The vision system also includes a feature for checking PCB output quality. CP6-43 is a high-performance unit designed to meet the needs of today's fast-paced assembly and manufacturing environments. It features a powerful soldering robot with four-axis control that can perform multiple assembly operations with speed and accuracy. FUJI CP6-43 is equipped with a powerful three-axis vision control machine that enables fine pitch component placement using the vision control technology. The tool also comes with an in-line surface mount technology (SMT) asset and a test socket assembly (TSA) unit that delivers accurate component placement. CP 643's combination of robotics, vision systems, and high-performance components, ensures efficient and accurate assembly of printed circuit boards. Its advanced features and sophisticated software make it possible to assemble high-quality products in a fraction of the time it takes with a manual assembly process.

There are no reviews yet