Used FUJI FDP-323M #9081474 for sale

URL successfully copied!

Tap to zoom

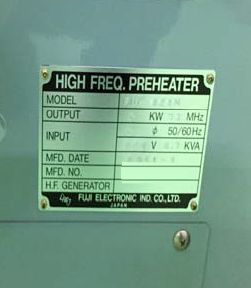

FUJI FDP-323M is a computerized assembly and manufacturing equipment designed for the production of high-density printed circuit boards (PCBs). The system is capable of producing complex boards with tight tolerance components with high reliability. It is an integrated solution that allows for precise assembly processes while still maintaining a high level of parts availability. The unit is designed to be highly reliable and efficient. It utilizes an on-board CPU to control all of the various assembly processes, from component placement to soldering. The machine can quickly indentify placement errors, and can easily be re-programmed to accommodate changes in the component mix. The tool is highly configurable, allowing users to adjust the placement and spacing of components to suit their particular needs. FDP-323M has a high speed component placers, capable of placing 22500 components per hour, providing 16 feeders for each head. It is able to handle large range of components sizes and types without a problem. It can also place components in a wide range of pitch intervals, from 0.4mm to 30mm. It is also equipped with an advanced vision asset to verify component placement and provide information about defective components. The soldering on FUJI FDP-323M is provided by a highly efficient infrared process. This process allows for rapid and accurate soldering of components to the board with minimal heat damage. It is also capable of applying flux in a controlled manner, ensuring that there is no excess flux on the board. It is also equipped with a pre-heater and temperature monitor to prevent overheating of components and solder. FDP-323M has an advanced user interface. It is capable of providing detailed reports on the production process, which can assist with controlling costs and identifying weak areas in production processes. The model also provides a range of advanced tools, such as defect detection, problem-solving trace and repair functions. It can also be integrated with third-party software to enable traceability of components and quality assurance. In summary, FUJI FDP-323M is a highly efficient and reliable solution for high-density PCB assembly and manufacturing. Its on-board CPU allows for precise production processes, its component placement capabilities are unmatched, and its soldering capabilities provide high-quality results. It is also highly configurable and provides real-time feedback and reporting capabilities. Overall, it is an ideal solution for producing complex and reliable PCBs with minimal downtime and maximum efficiency.

There are no reviews yet