Used FUJI IP1 #293630459 for sale

URL successfully copied!

Tap to zoom

ID: 293630459

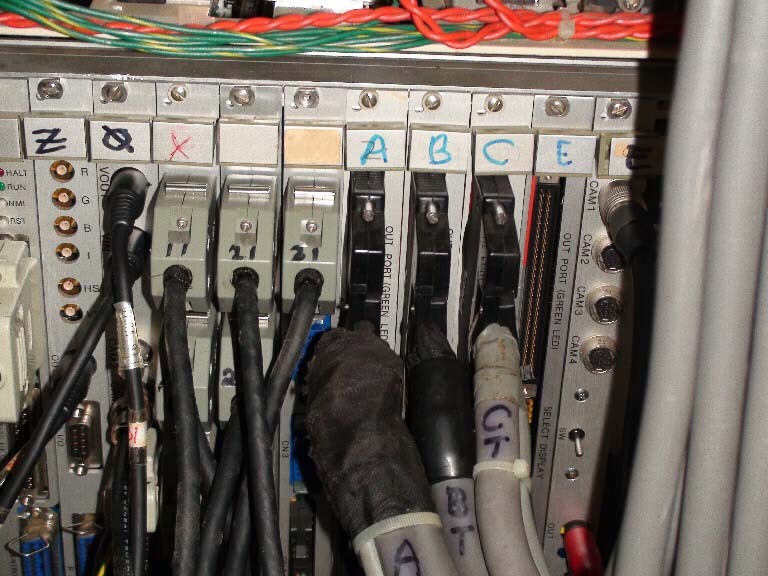

Pick and place machine

Actus servo amplifiers

PC: MCS-16F

Keyboard

Motors

Cameras

Nozzles

Circuit boards

Power supply

Qty / Feeders:

(34) / W8x4-TD

(12) / W8x4-TE

(10) / W8P1D

(5) / W12x8-TE

(7) / W16x8-TE

(6) / W16x12-TE

(1) / W44x32

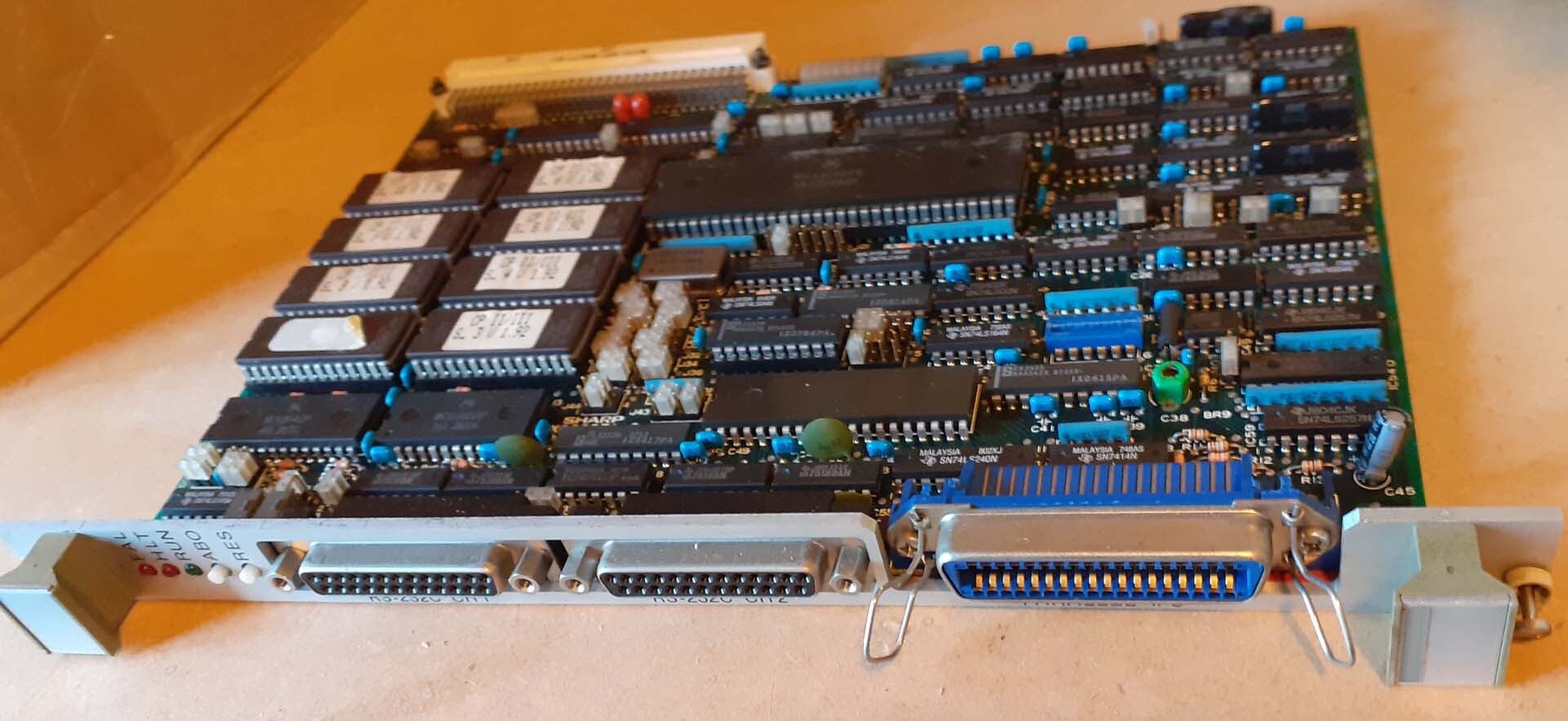

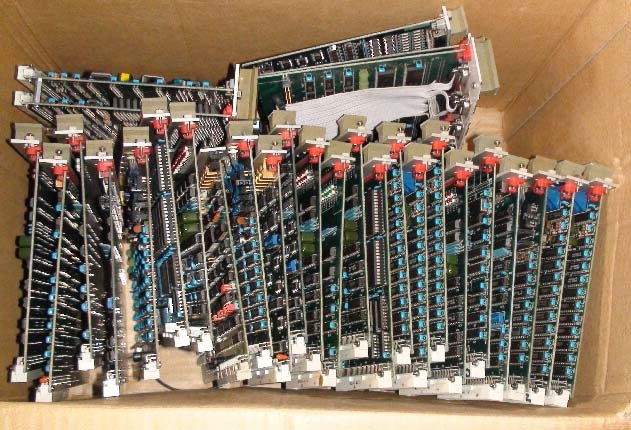

Additional spare Fuji parts and VME bus PCB’s:

Motionpack-34: Yaskawa Electric SN RUP189-524-11

Servopack DR1-04AA NOOA: Yaskawa electric SN 483311-1-8

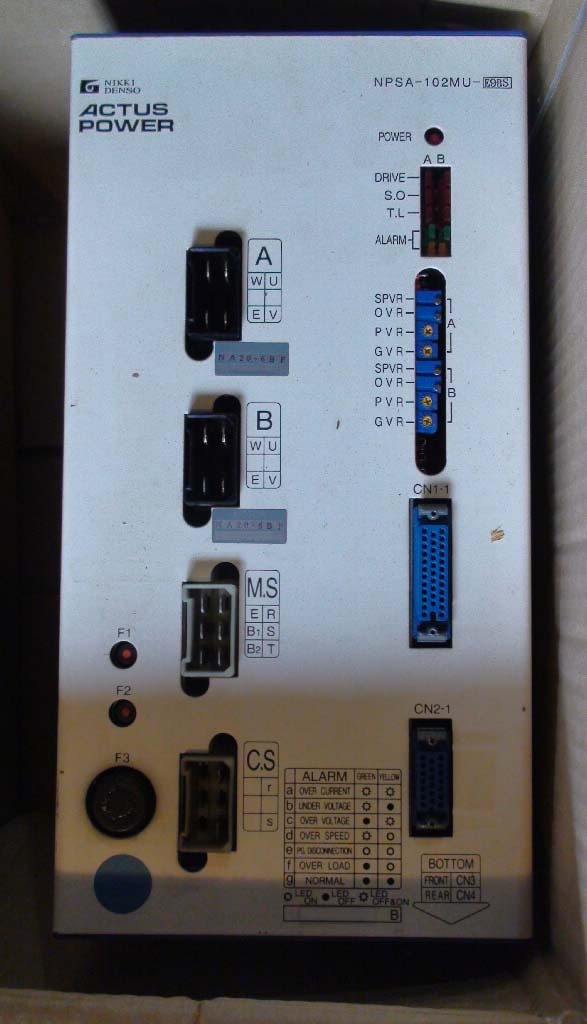

(2) Niki Denso Actus Power NPSA-102MU

Niki Denso Actus Power NPSA-103MU

Niki Denso Actus Power NPSA-104MU

(3) FH1001 Display I/O cards

FH1002 RGB video card

TVME300 CRTC Keyboard / Printer I/O card

(4) VM1110TA Parallel I/O cards

(3) VM1152S

VM1160A

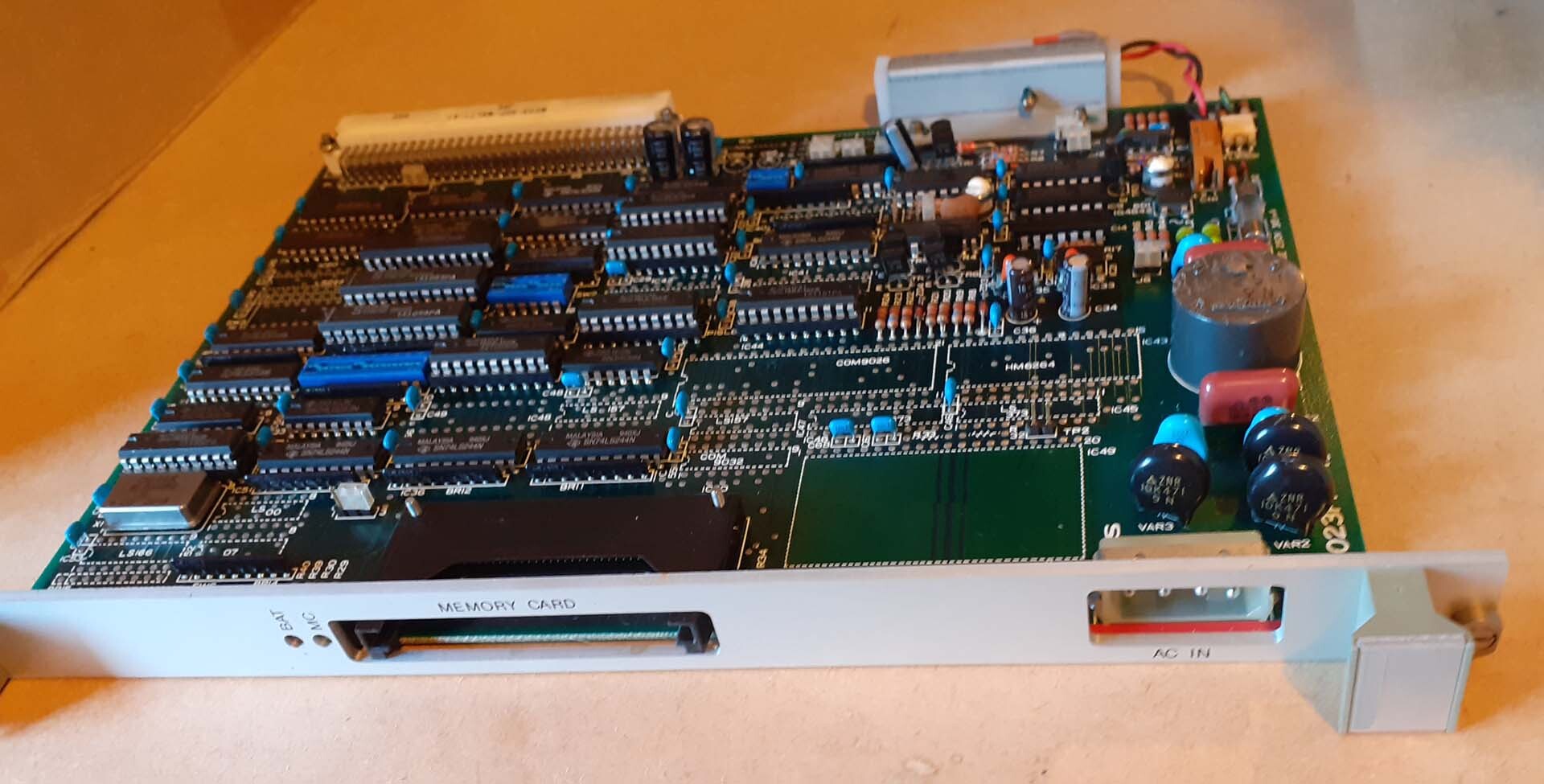

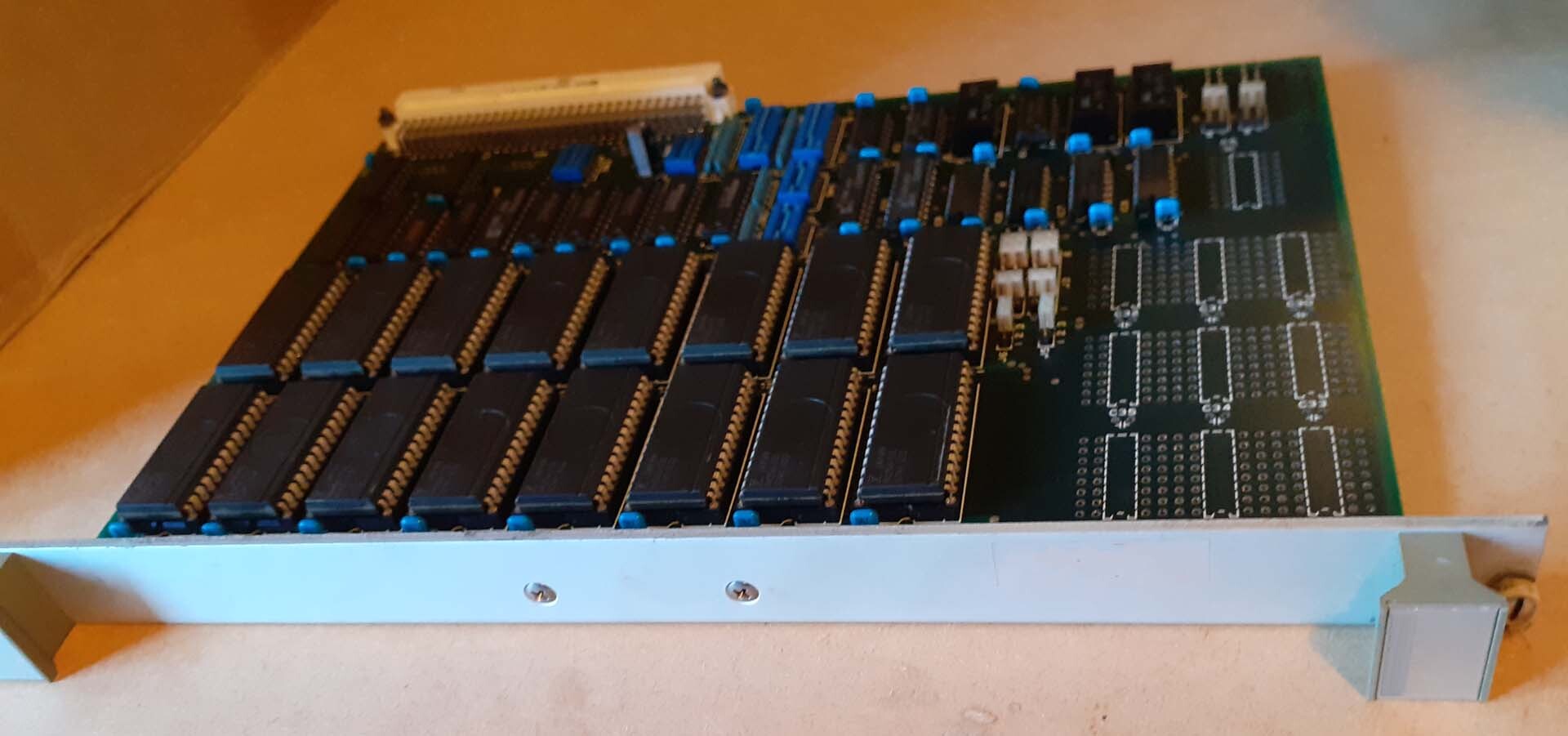

(2) VM1220 Memory cards

VM1310

VM1410 8 channel serial port card

(2) VM1510 Input I/O boards

(5) VM1520

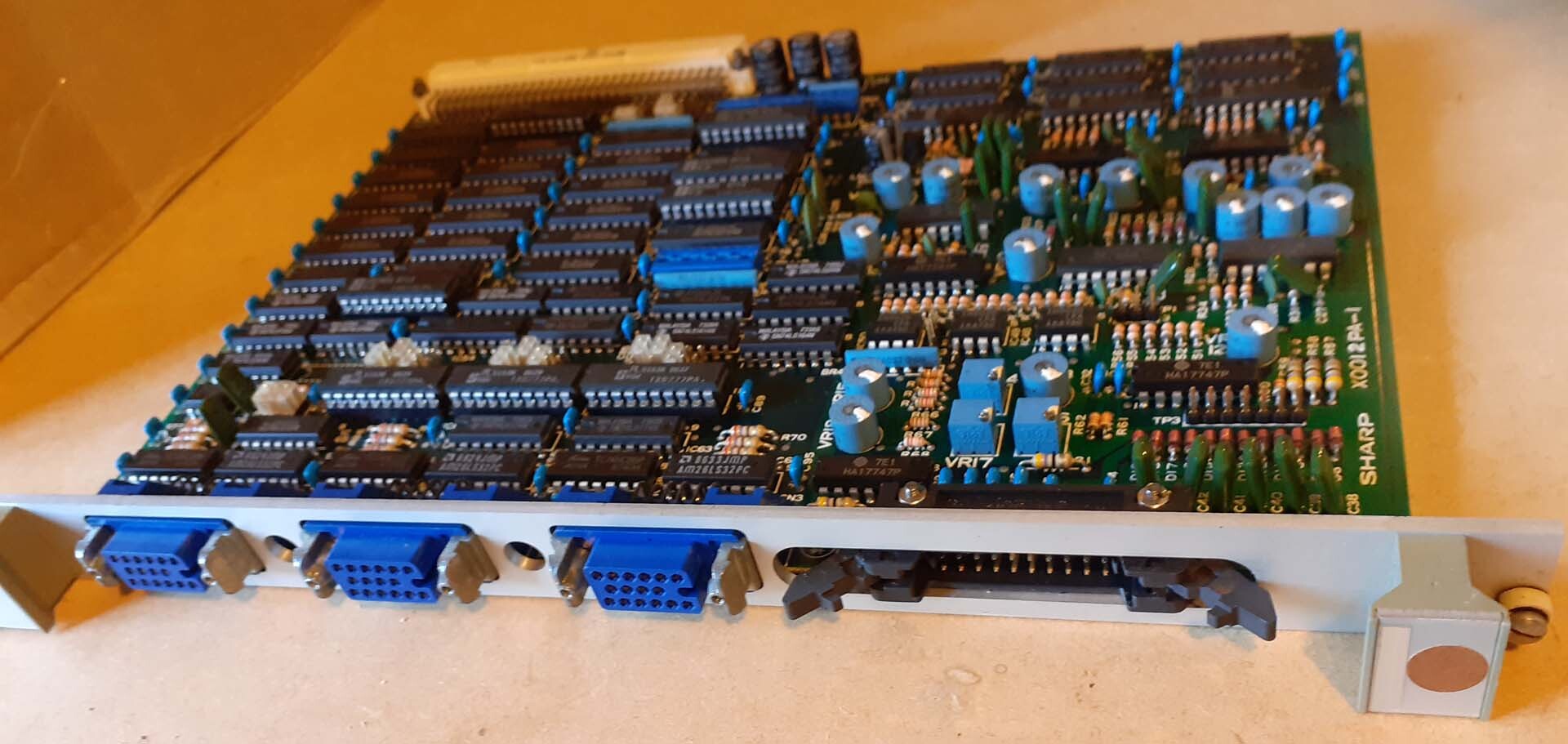

(5) VM1530 Servo card

VM1540 Display I/O card

VM1610 Video card

(3) VM1710 Camera I/O cards

(2) VM1931 Memory cards

XC-37 Daito CCD Video camera module with DC-37 Power Module

CDT-922B-5 Color display, 9".

FUJI IP1 is a fully automated, high-speed pc board assembly and manufacturing equipment that is specifically designed for use in demanding, high-volume production environments. It is capable of handling a wide range of different components and materials as well as executing many different assembly processes. IP1 is a highly efficient production system, offering cost-effective, reliable and consistent results. FUJI IP1 is a highly advanced unit that is equipped with a range of sophisticated control mechanisms. It features a high-speed image recognition and visual recognition machine which allows the tool to efficiently scan and recognize the components used in assembly. This allows the asset to precisely determine the part's position and orientation within the assembly line before assembling it. IP1 also features an integrated motion control model. This equipment enables the system to quickly move components from the in-feed assembly line to the out-feed assembly line with the utmost accuracy. The unit's sophisticated motion control machine is able to accurately and quickly place components such as solder paste, screws and surface mount components into their designated places quickly and accurately. Additionally, the tool is also able to accurately locate components by using its built-in vision asset and performing pick-and-place operations. FUJI IP1 features some of the most advanced automated manufacturing processes available in the industry. It is capable of performing a wide range of tasks, including chip-on-board assembly, reflow soldering, stencil printing and conformal coating. The model also features a built-in automated optical inspection equipment, which ensures that all components and assemblies are assembled correctly, reducing the potential for errors. IP1 is also fully compatible with a range of different pc board designs, including Flex and Rigid-Flex pc boards. This gives manufacturers' the flexibility to create various designs and constructions of pc boards. FUJI IP1 is an advanced pc board assembly and manufacturing system that exceeds the highest industry standards in pc board assembly. Its sophisticated control mechanisms and advanced automated manufacturing processes provide cost-effective and reliable solutions for high-volume production environments. IP1 provides manufacturers with the flexibility and efficiency needed to meet the highest industry standards.

There are no reviews yet