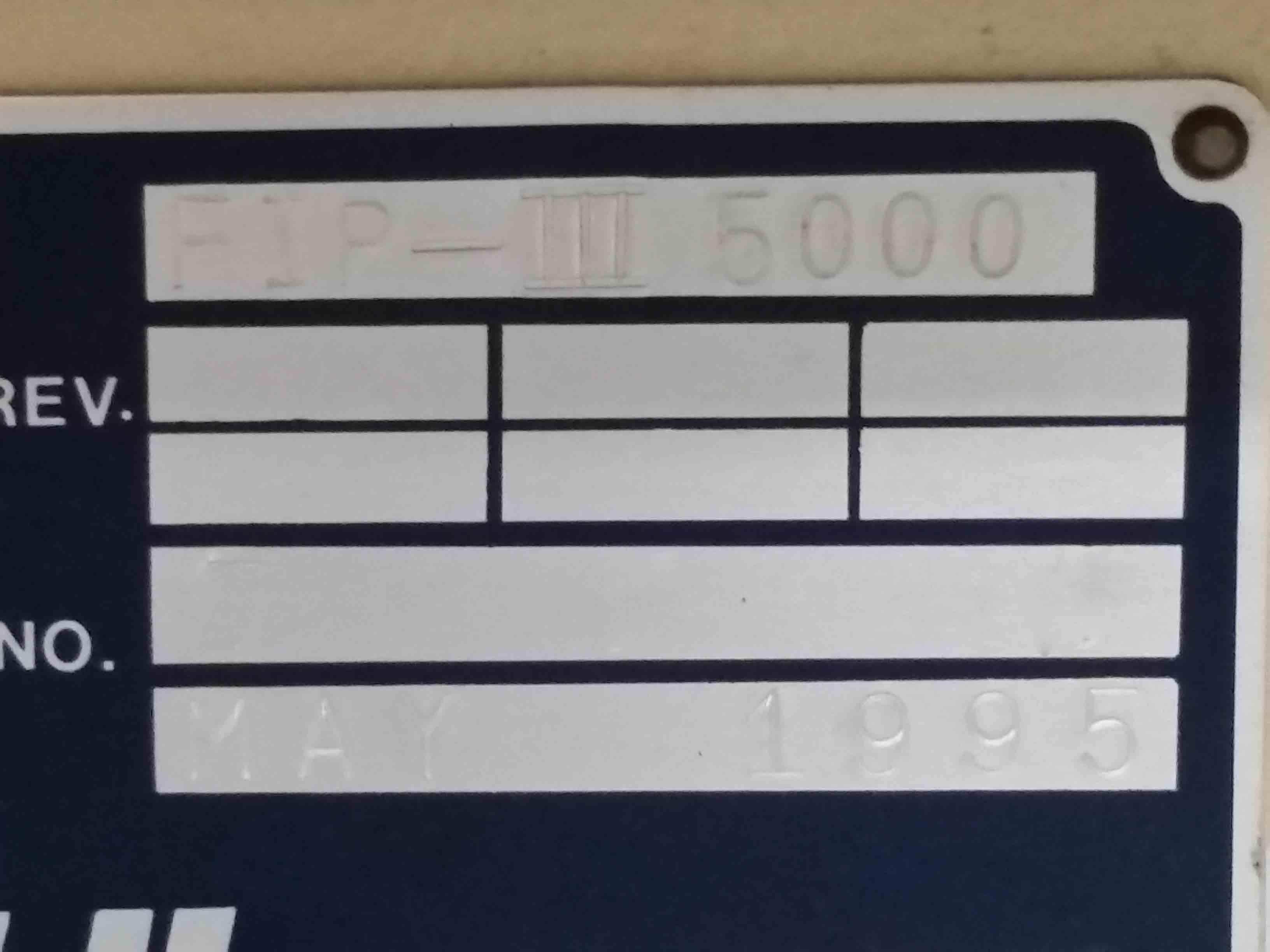

Used FUJI IP3-5000 #9212423 for sale

URL successfully copied!

Tap to zoom

FUJI IP3-5000 is a high-performance, pc board assembly and manufacturing equipment designed for a variety of production needs. The system is designed for a single zone of production, enabling maximum work cell productivity and reducing cost of offline tooling changeover. IP3-5000 is capable of producing multi-layer PC boards through its advanced combination of placement, inspection and process control technologies. FUJI IP3-5000 is built around the latest production line automation technology, allowing the user to easily integrate several components into a single delivery unit and create real-time production control systems with multitask controls. IP3-5000 incorporates high-end placement technology with its high speed, multi-layer 4-mode head. This superior 4-mode head allows for simultaneous placement of surface mount, through hole, press-fit and cut-tape components. The machine also features both dual and quaternary head capability for different mixes of components. The machine also includes a 240mm panelized assembly capability for higher level productivity, enabling speeds up to 5000CPM. FUJI IP3-5000 also includes inspection features for quality assurance, such as a 5MP digital camera and a 3D dimensional inspection tool with inspection resolutions up to 0.1 mm. The camera and its associated optical magnification lens allow up to 40,000 components to be checked for proper placement and solder joints, enabling automatic placement defects to be reliably detected. The 3D dimensional inspection asset is comprised of a double-headed camera model which inspects every side of a given component using a laser triangulation technique to determine correct placement. IP3-5000 also incorporates a robust process control equipment which facilitates repeatable quality processes. This system allows for cross-platform component verification, temperature and flow control for precise solder paste dispensing, as well as intricate process control algorithms that are regularly updated in order to keep up with the ever-changing needs and requirements of production. Finally, FUJI IP3-5000 incorporates an intuitive graphical user interface featuring sophisticated data monitoring and production trending. This interface includes dedicated windows for setup and diagnostics which are easily navigable and user-friendly. FUJI PC board assembly and manufacturing unit is designed to allow for quick and easy setup, real-time production monitoring, as well as detailed report generation and analysis. In summary, IP3-5000 is a high-performance production machine capable of producing multi-layer pc boards with a host of features designed for maximum efficiency and quality assurance. The advanced components, sophisticated user interface and process control algorithms provide the user with everything they need to keep their production up and running with minimal downtime.

There are no reviews yet