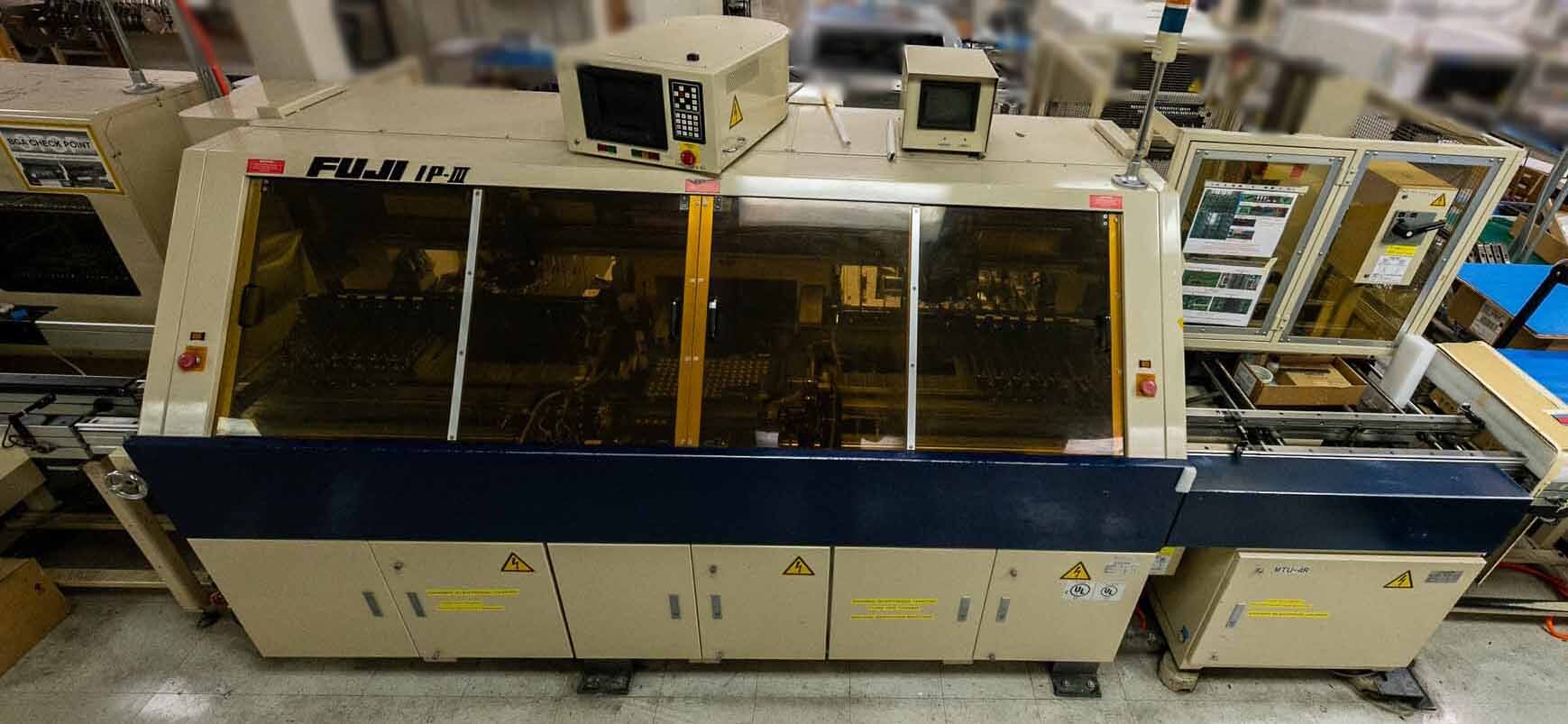

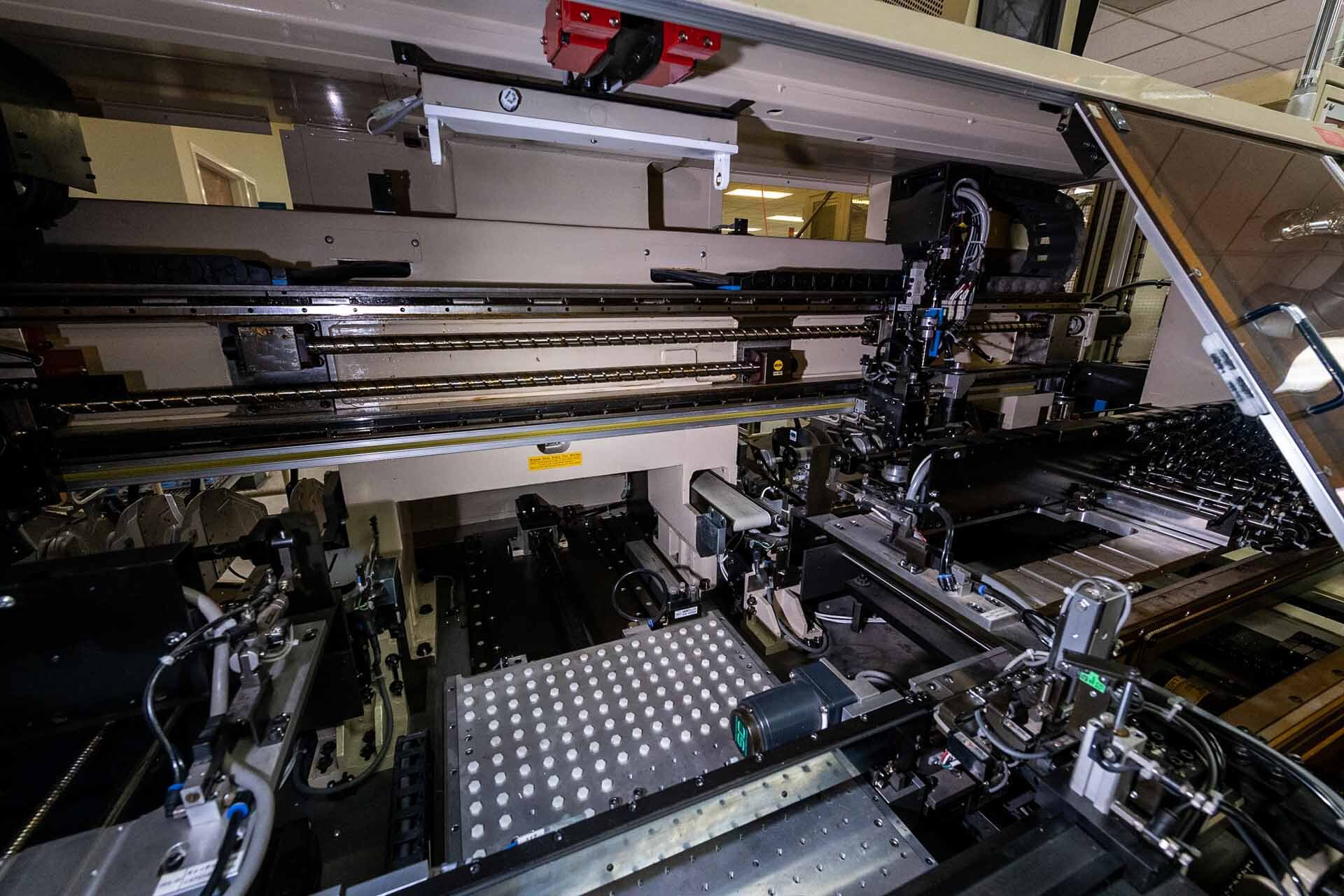

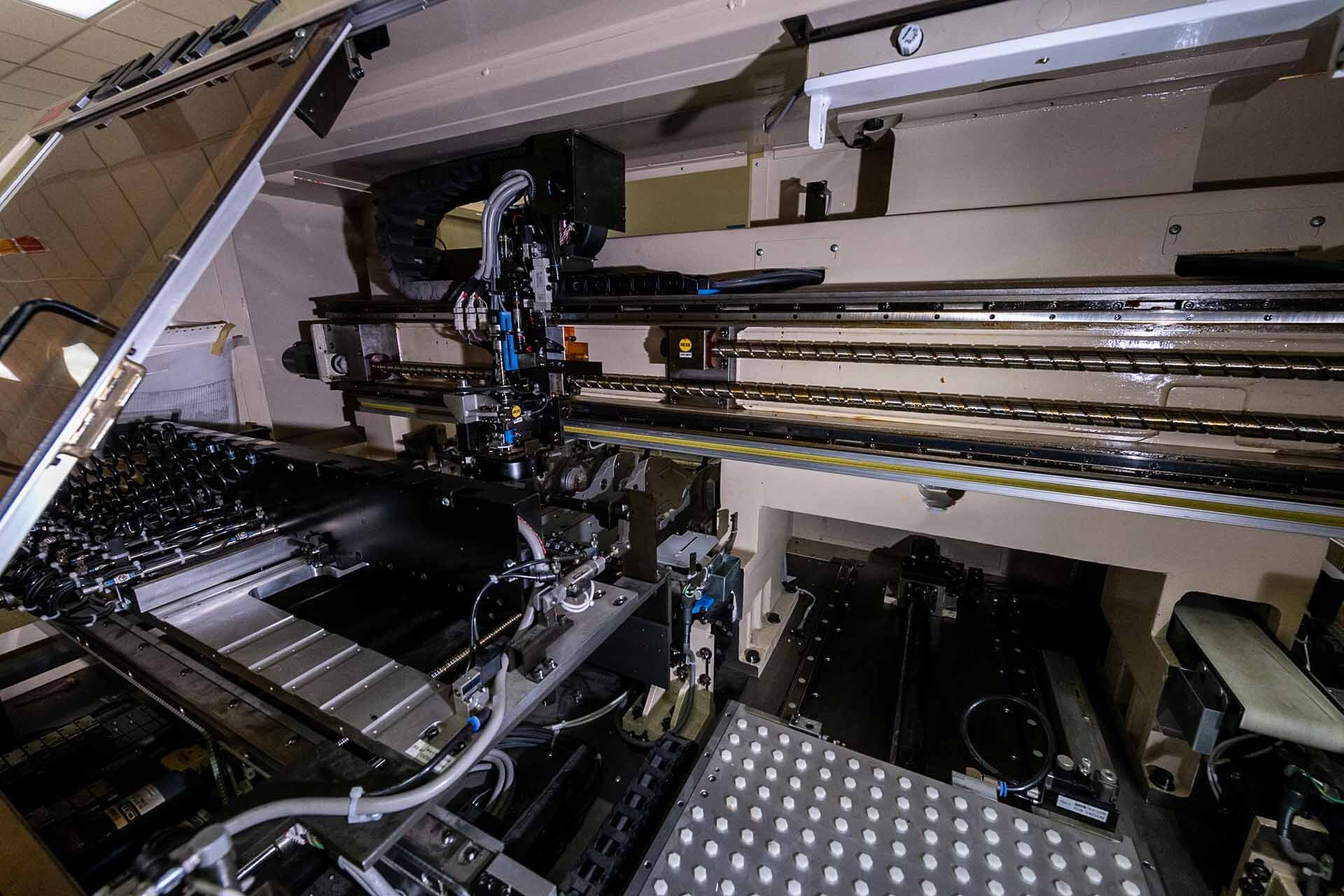

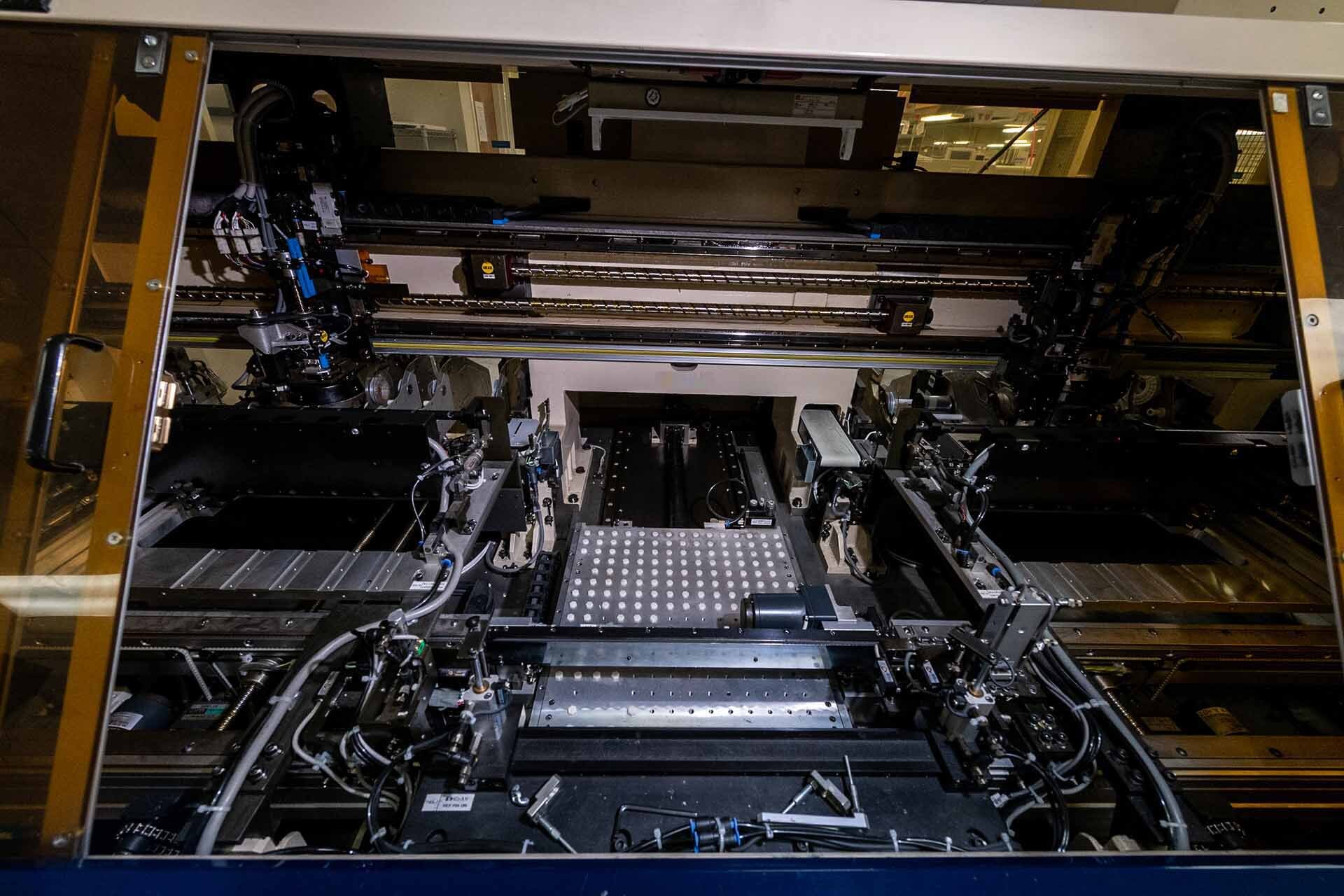

Used FUJI IP3 #293616546 for sale

URL successfully copied!

Tap to zoom

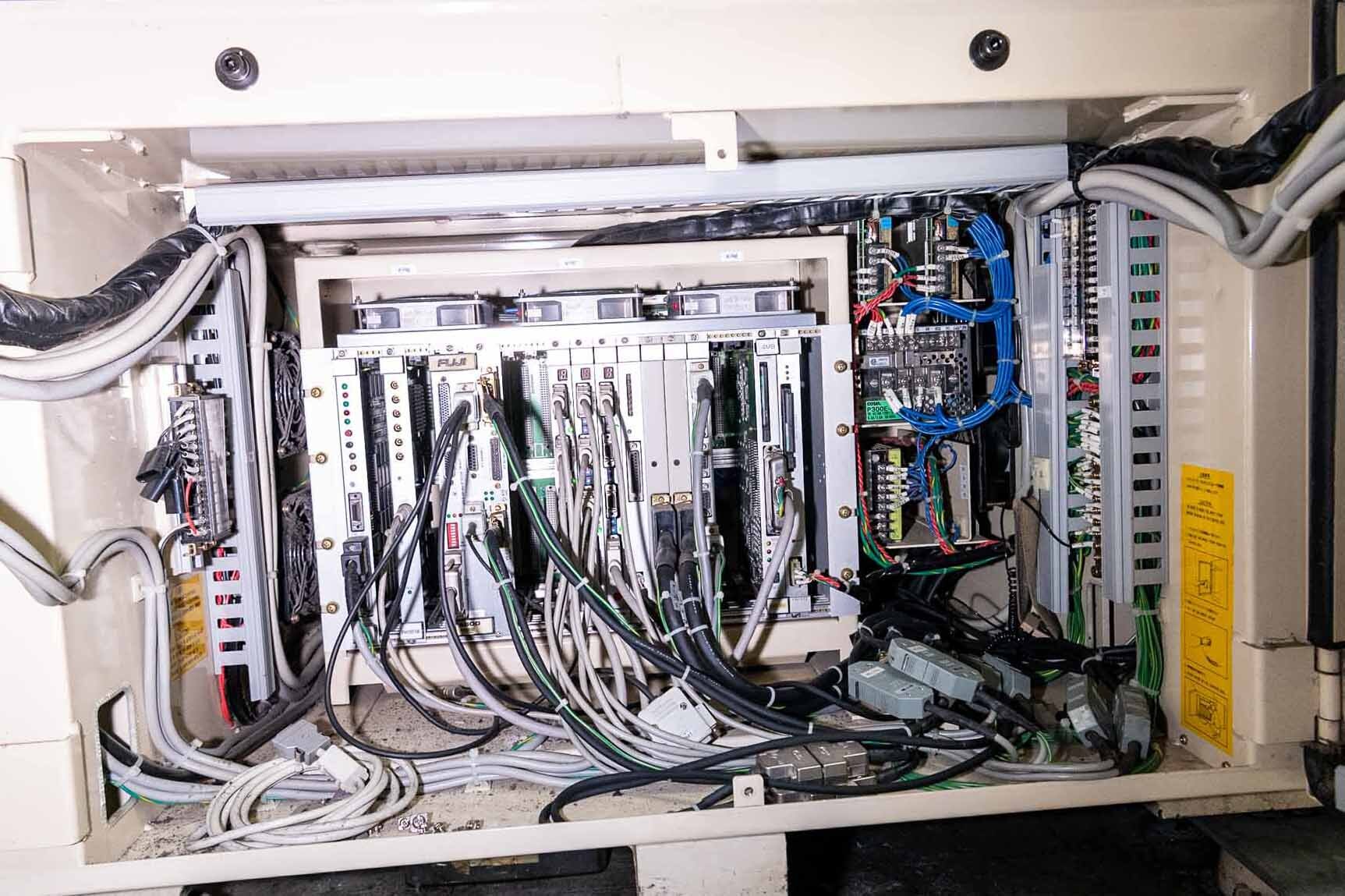

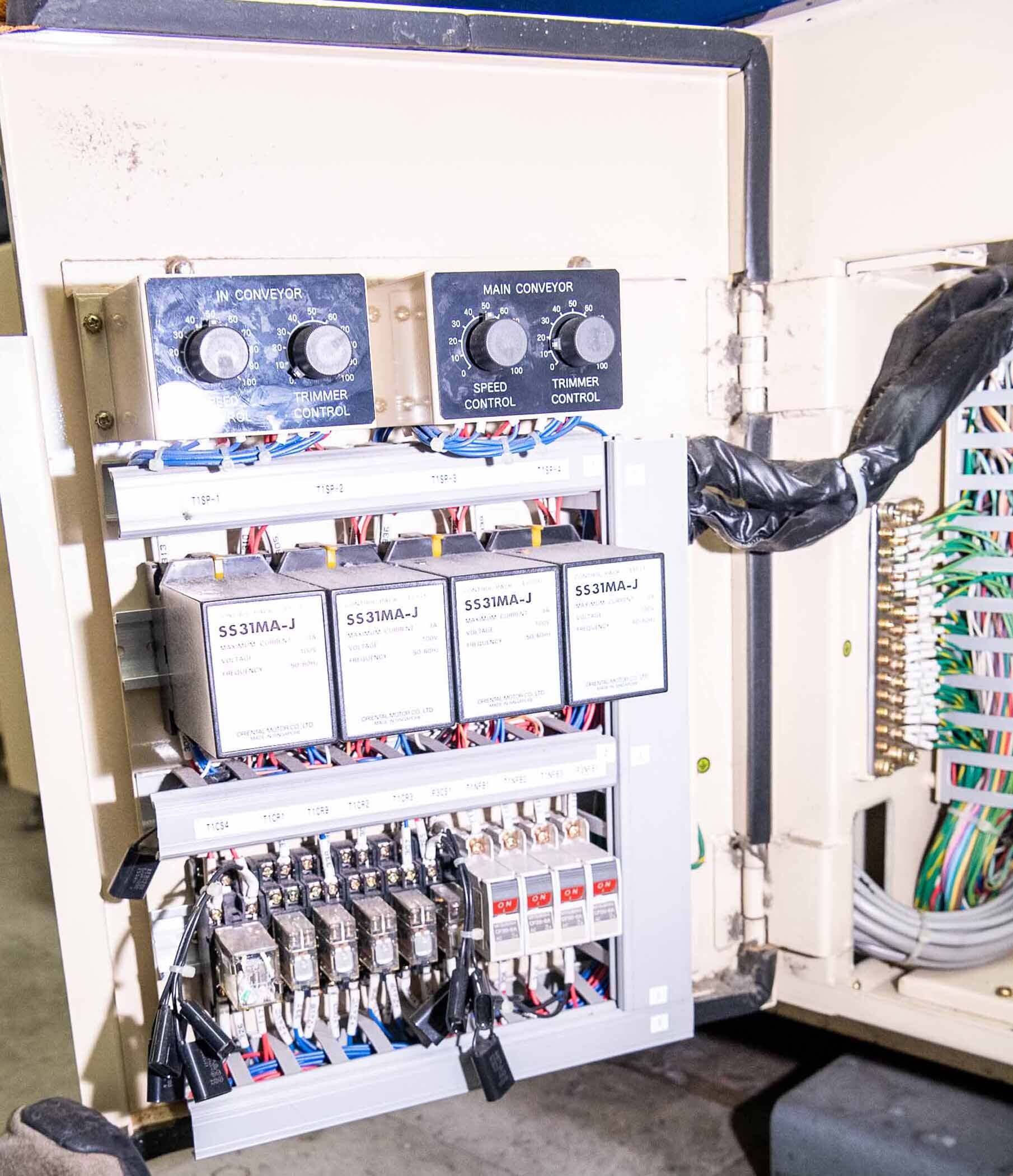

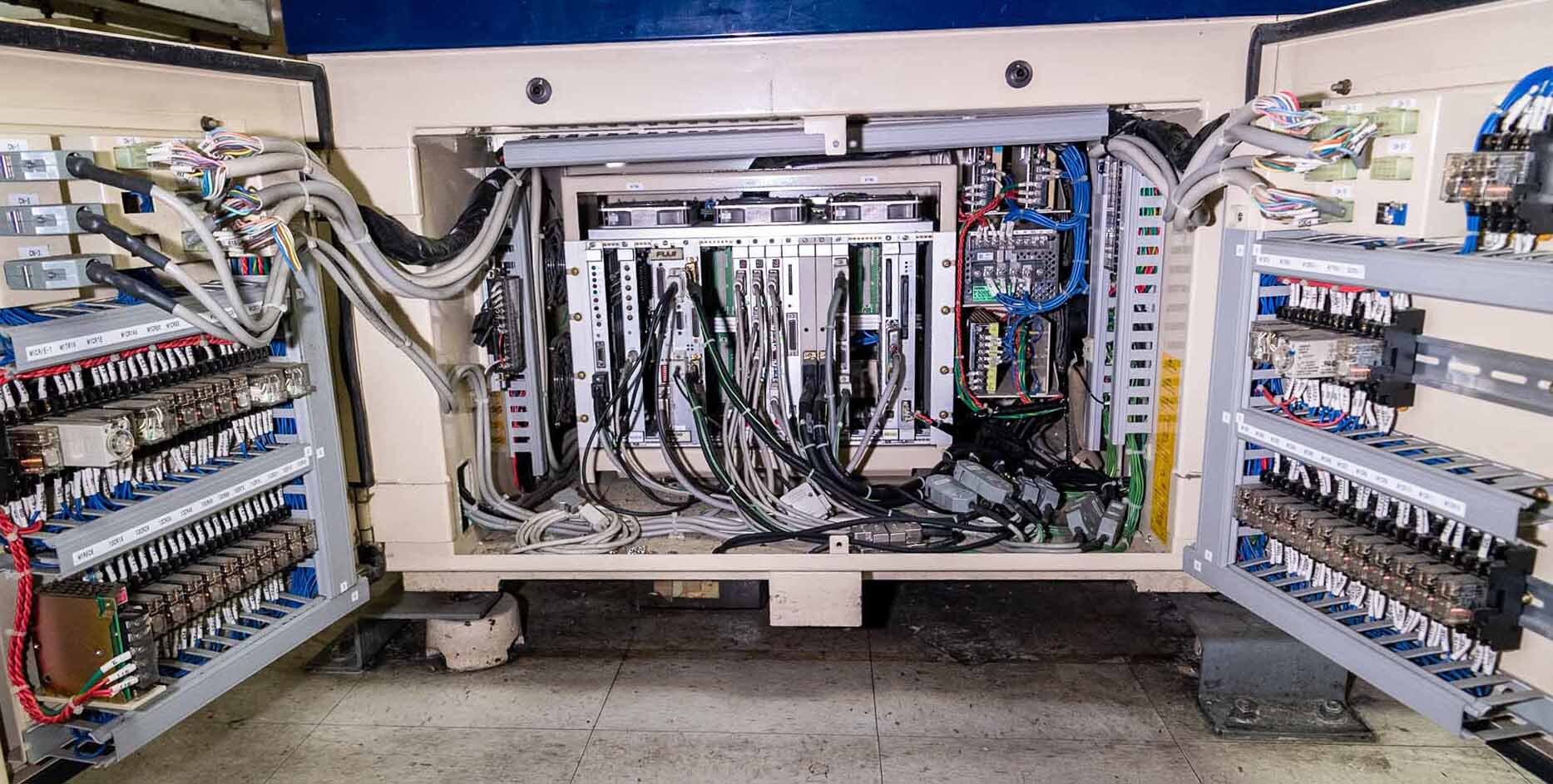

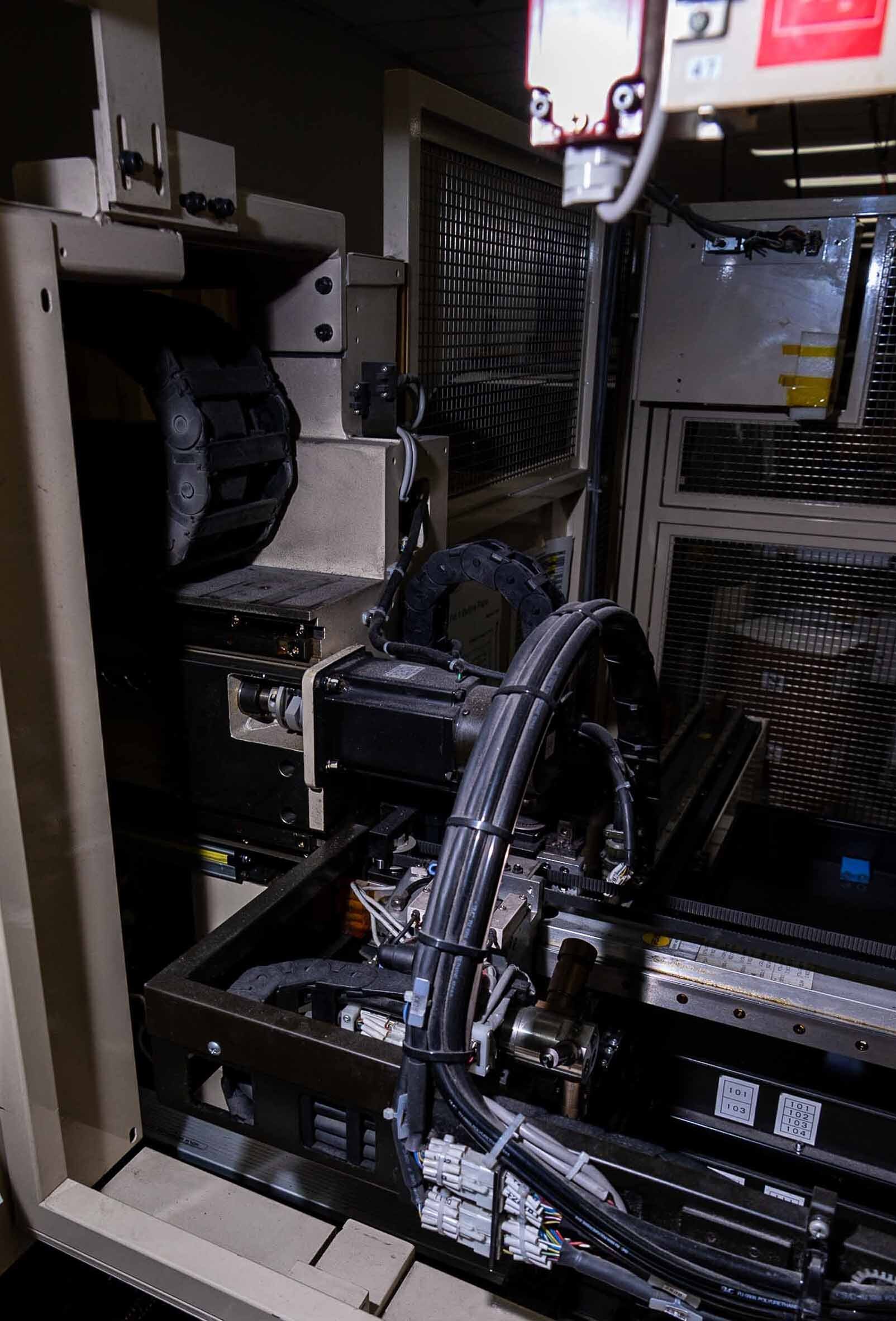

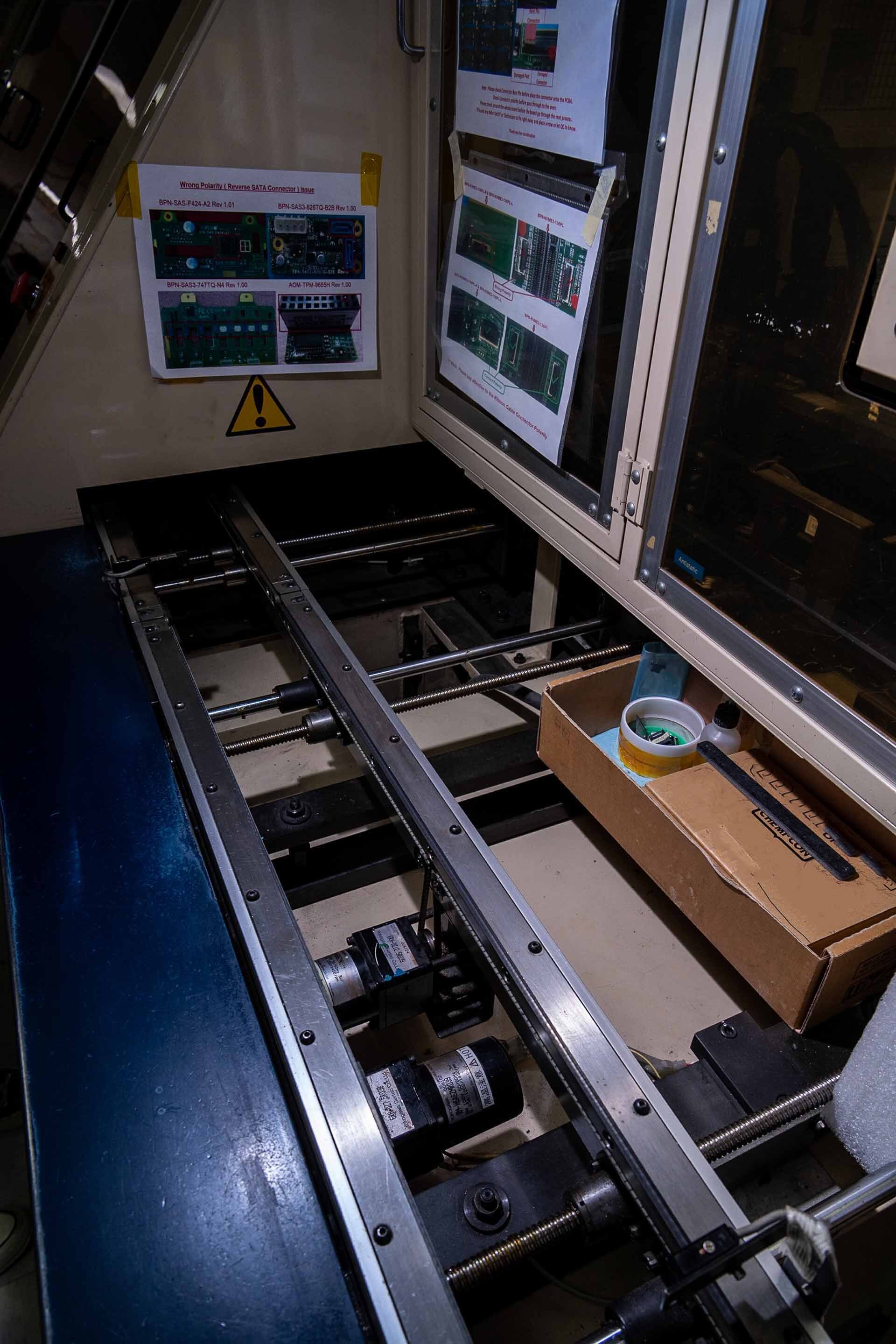

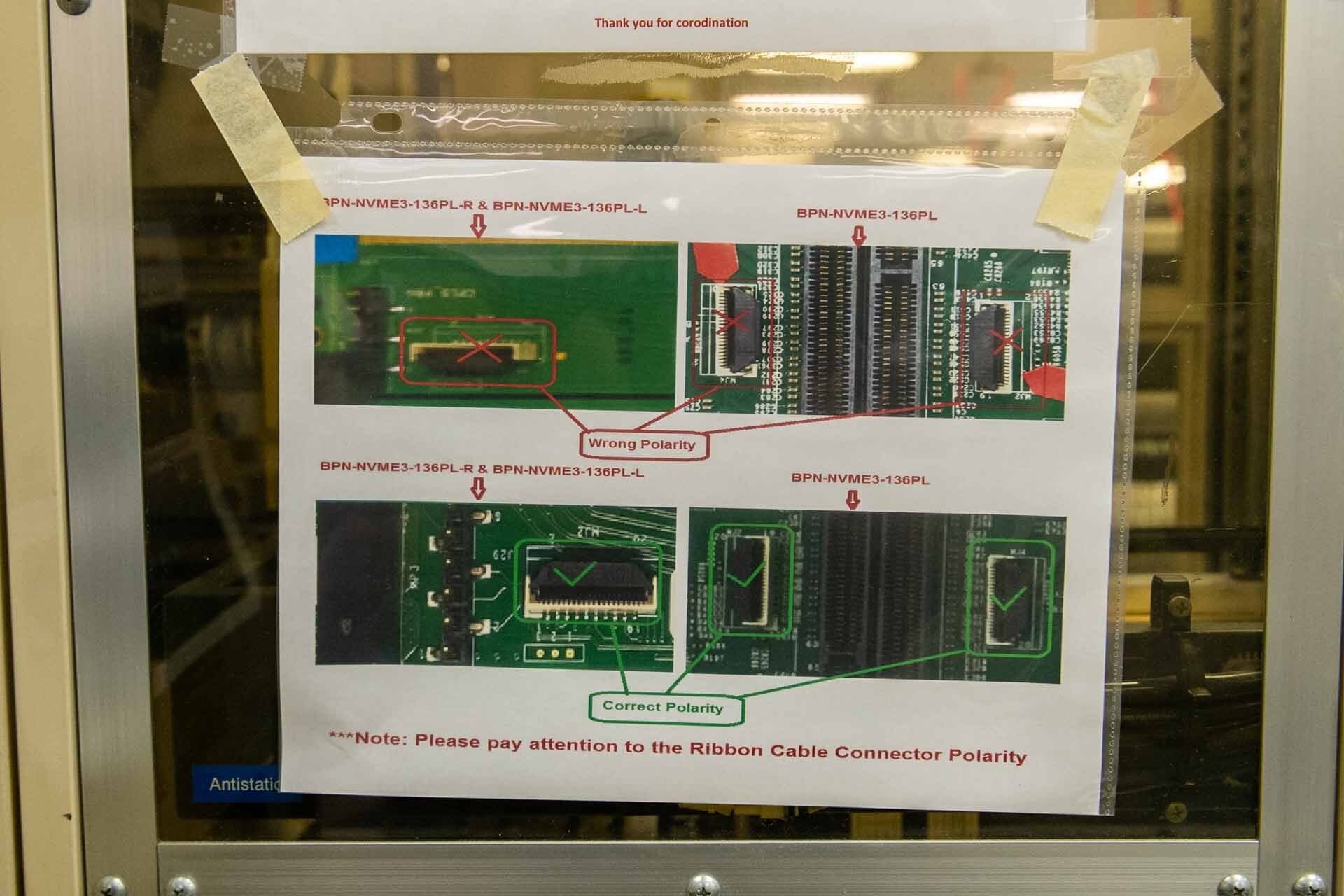

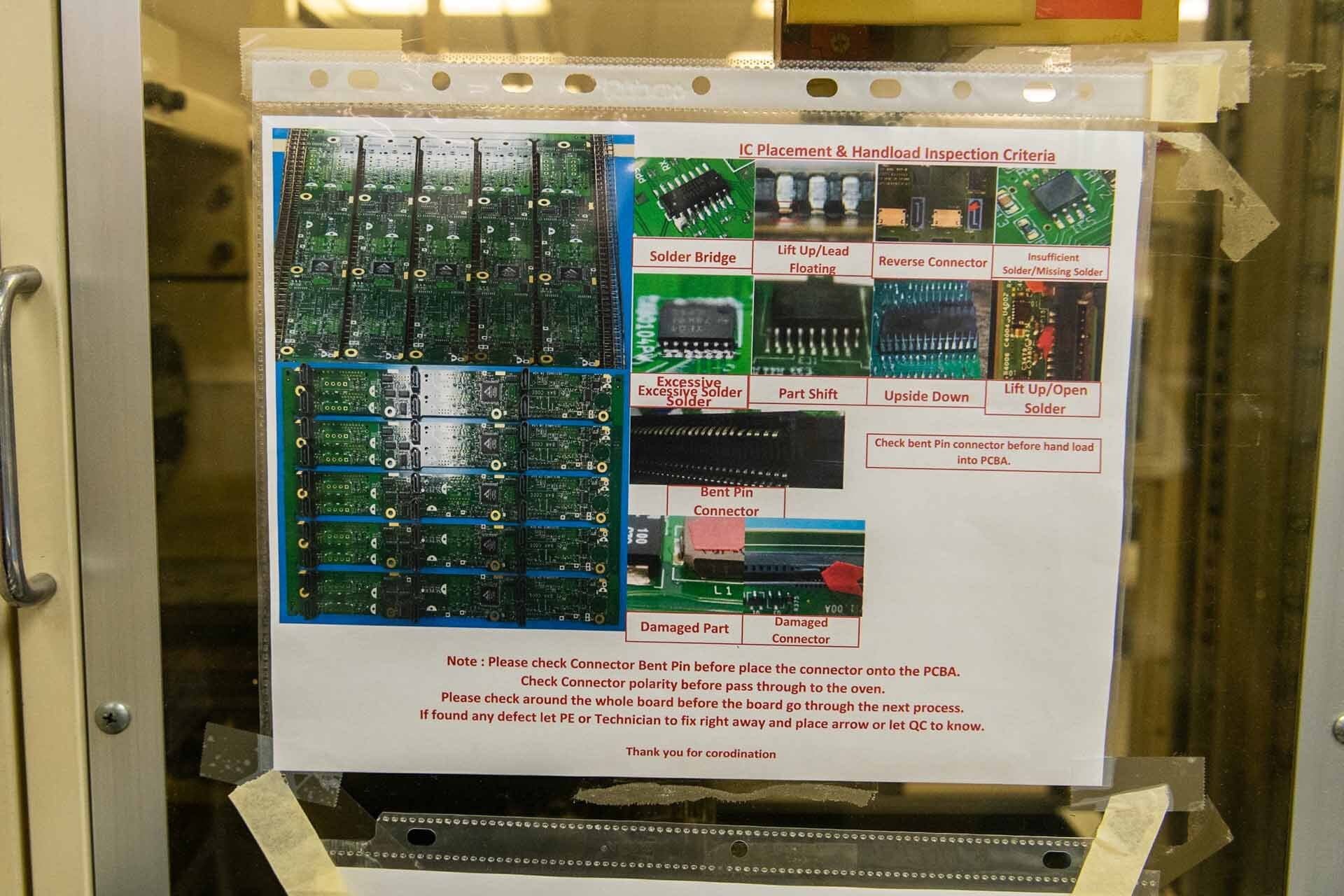

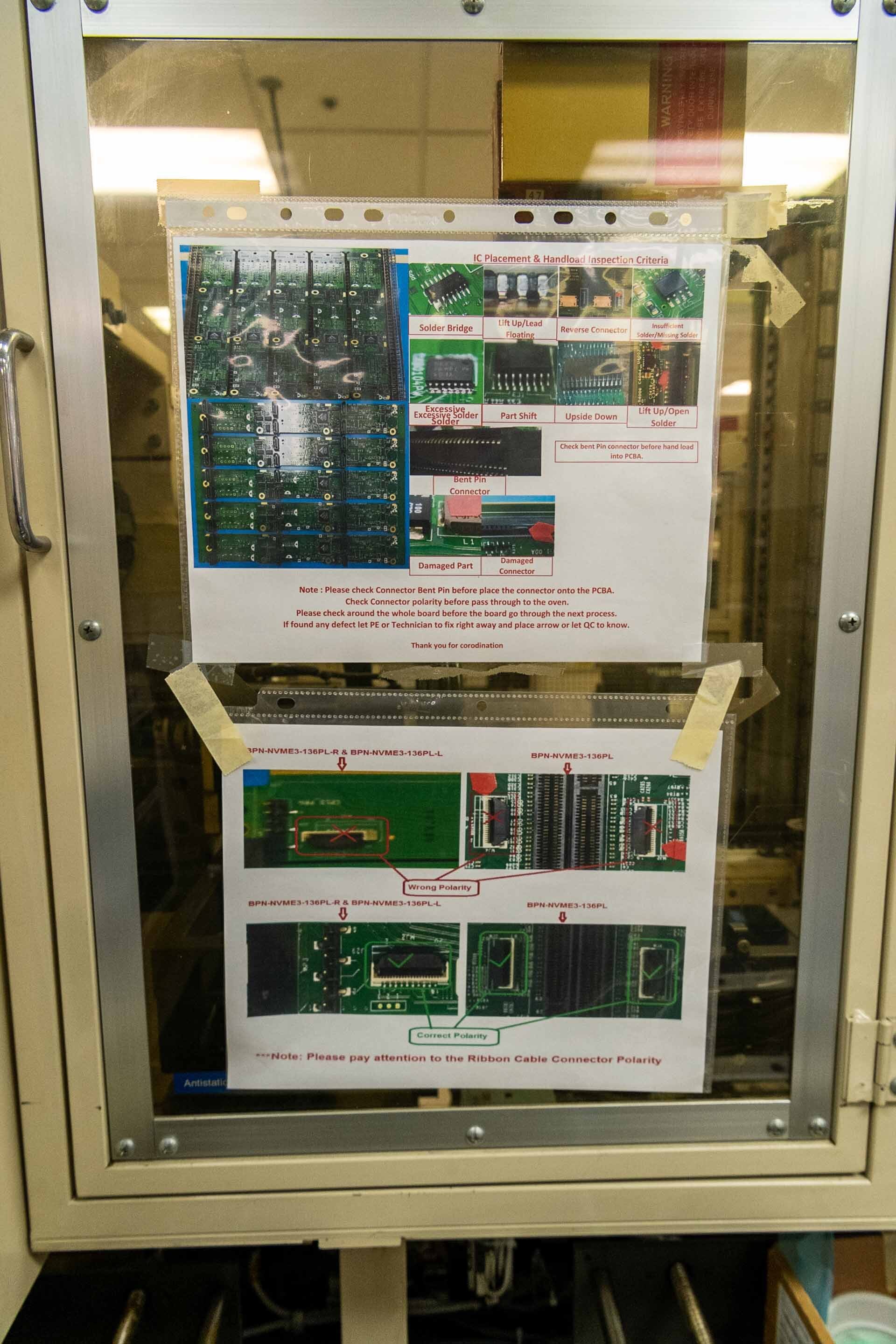

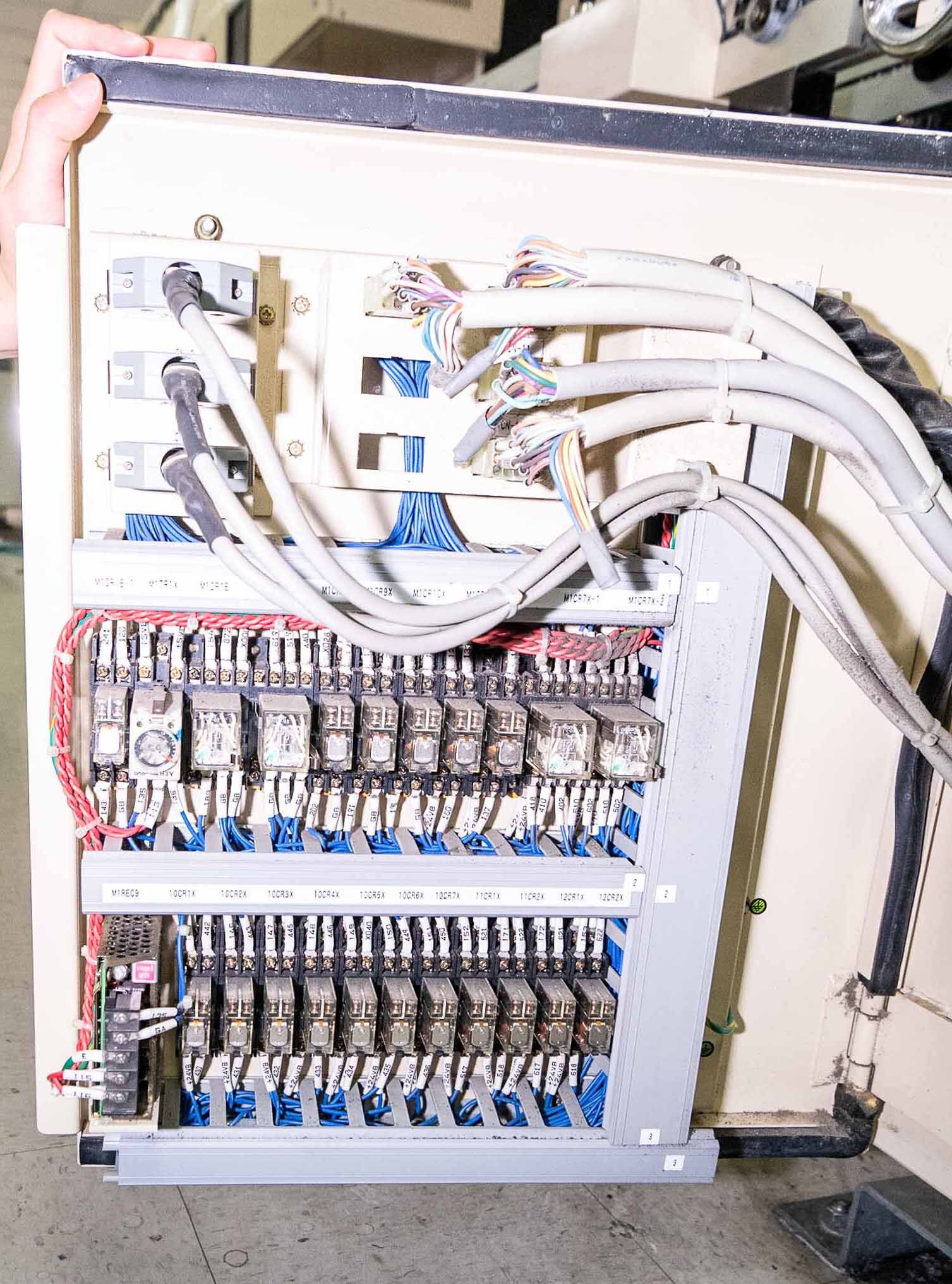

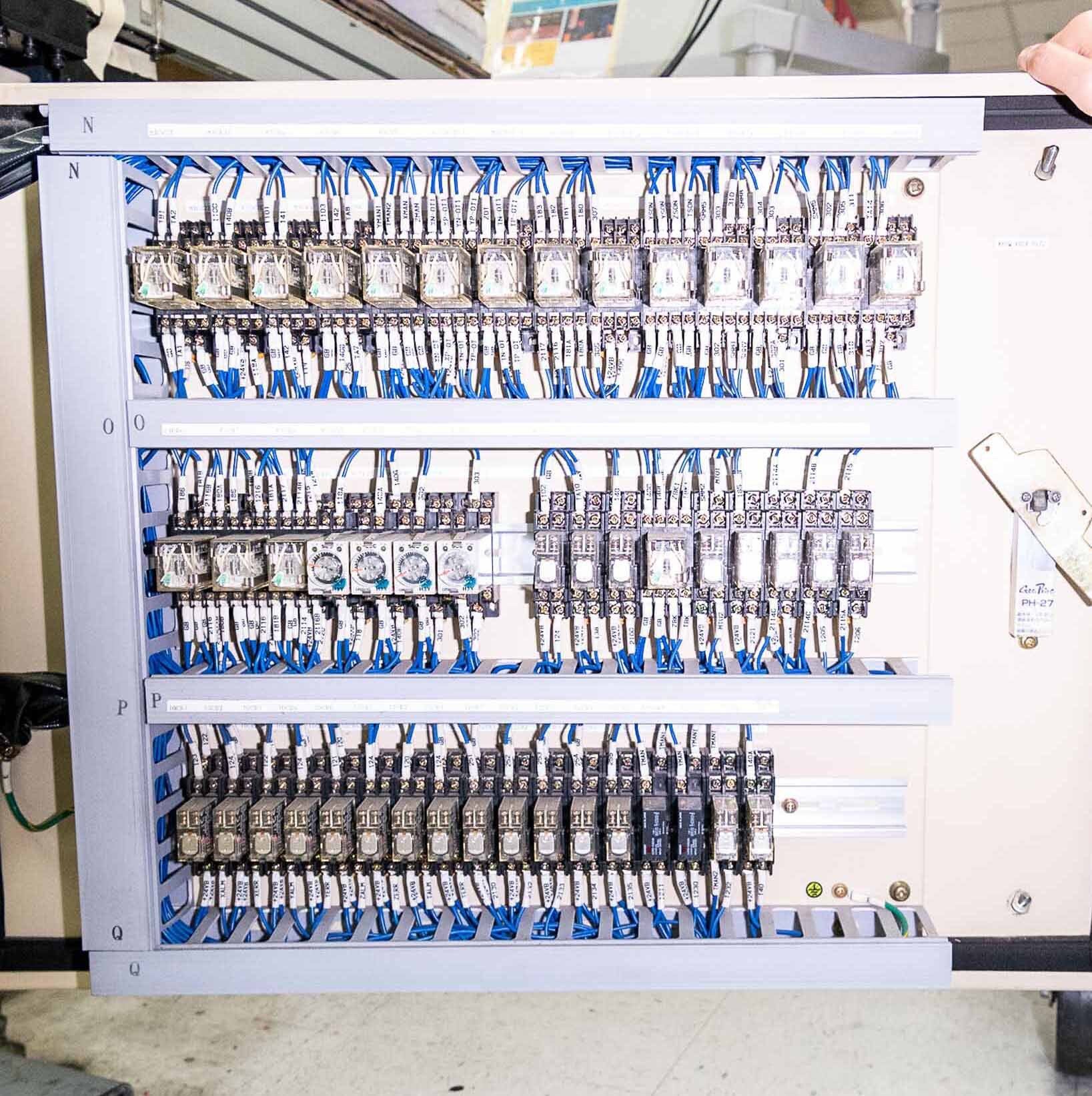

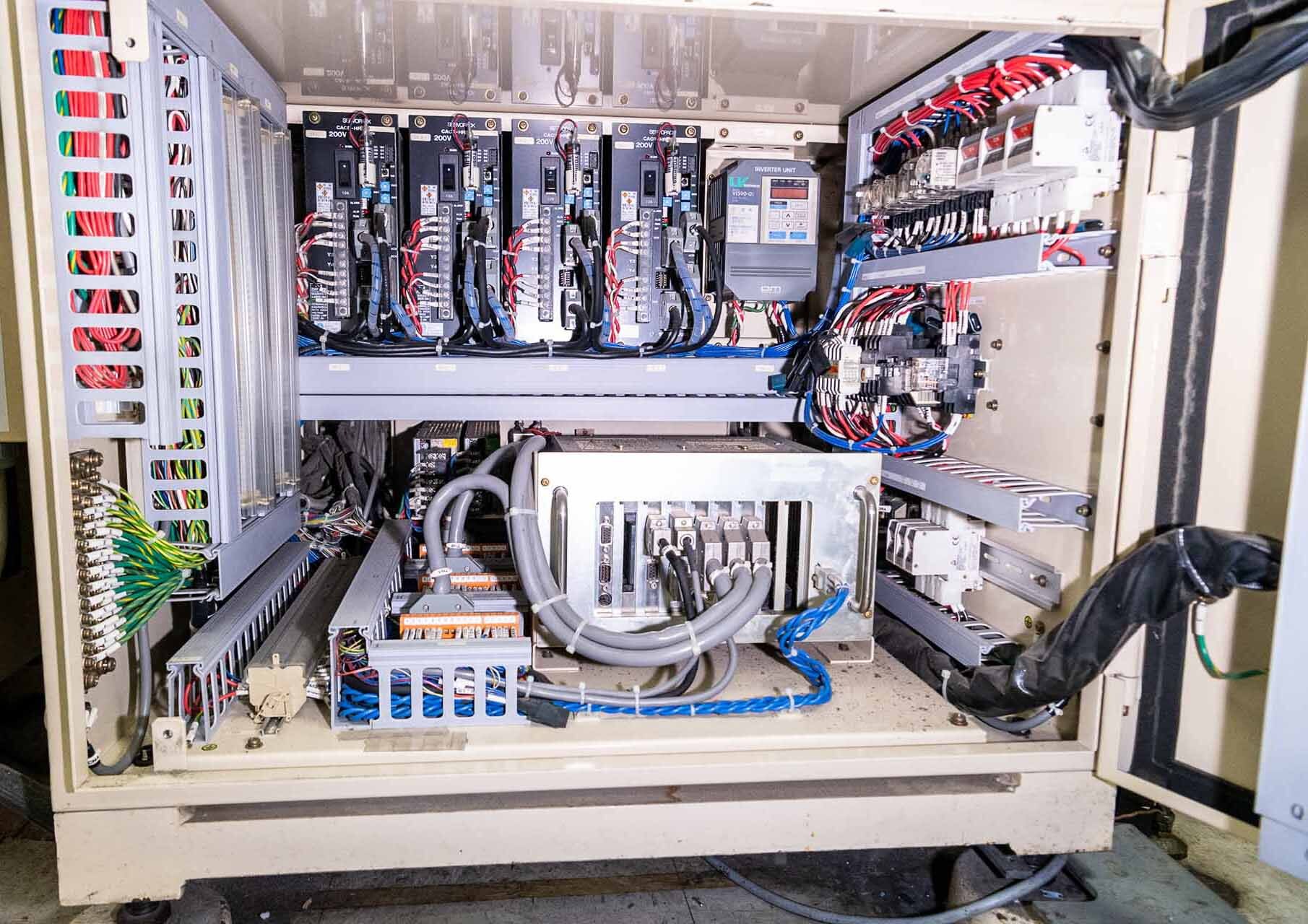

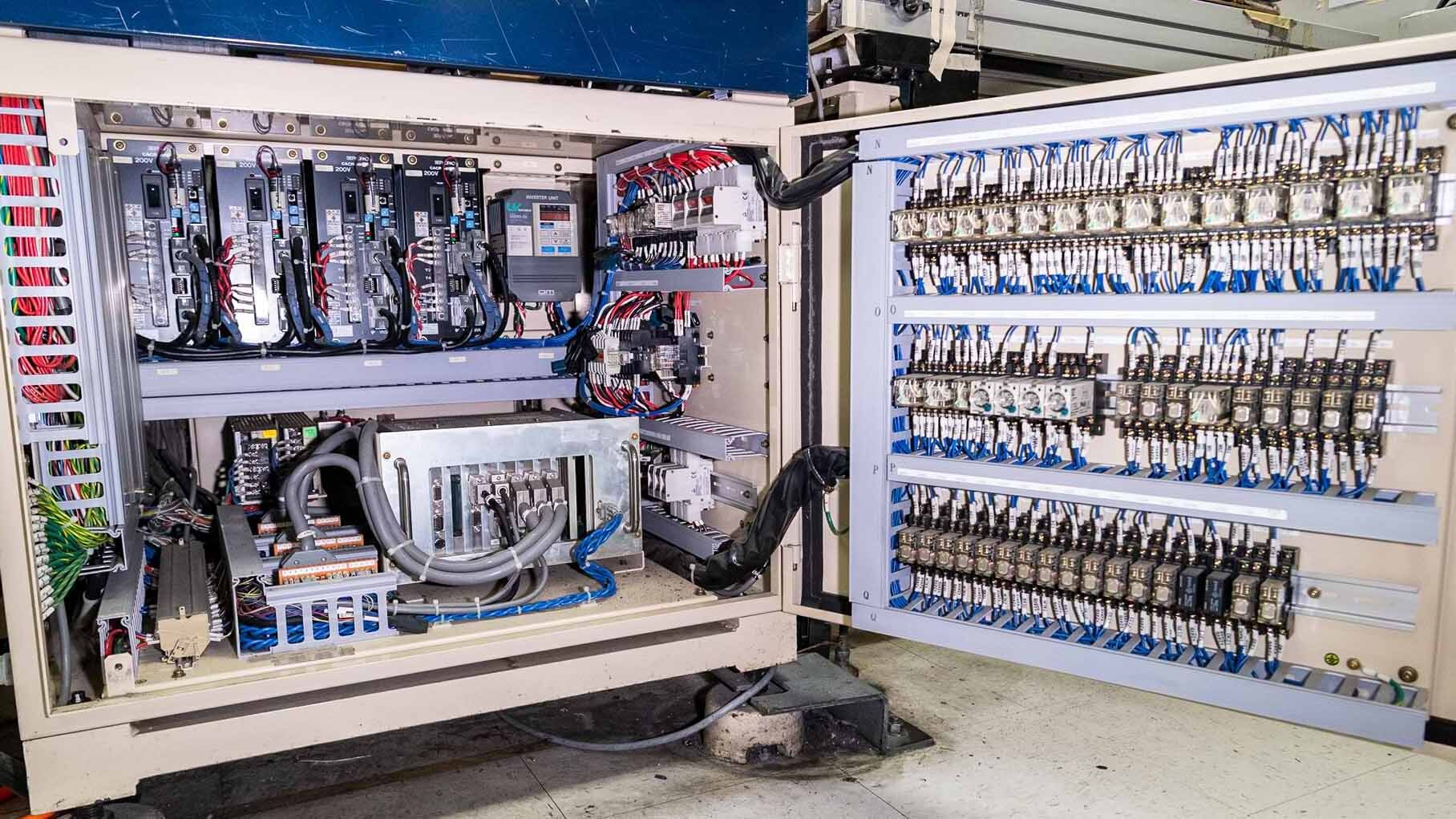

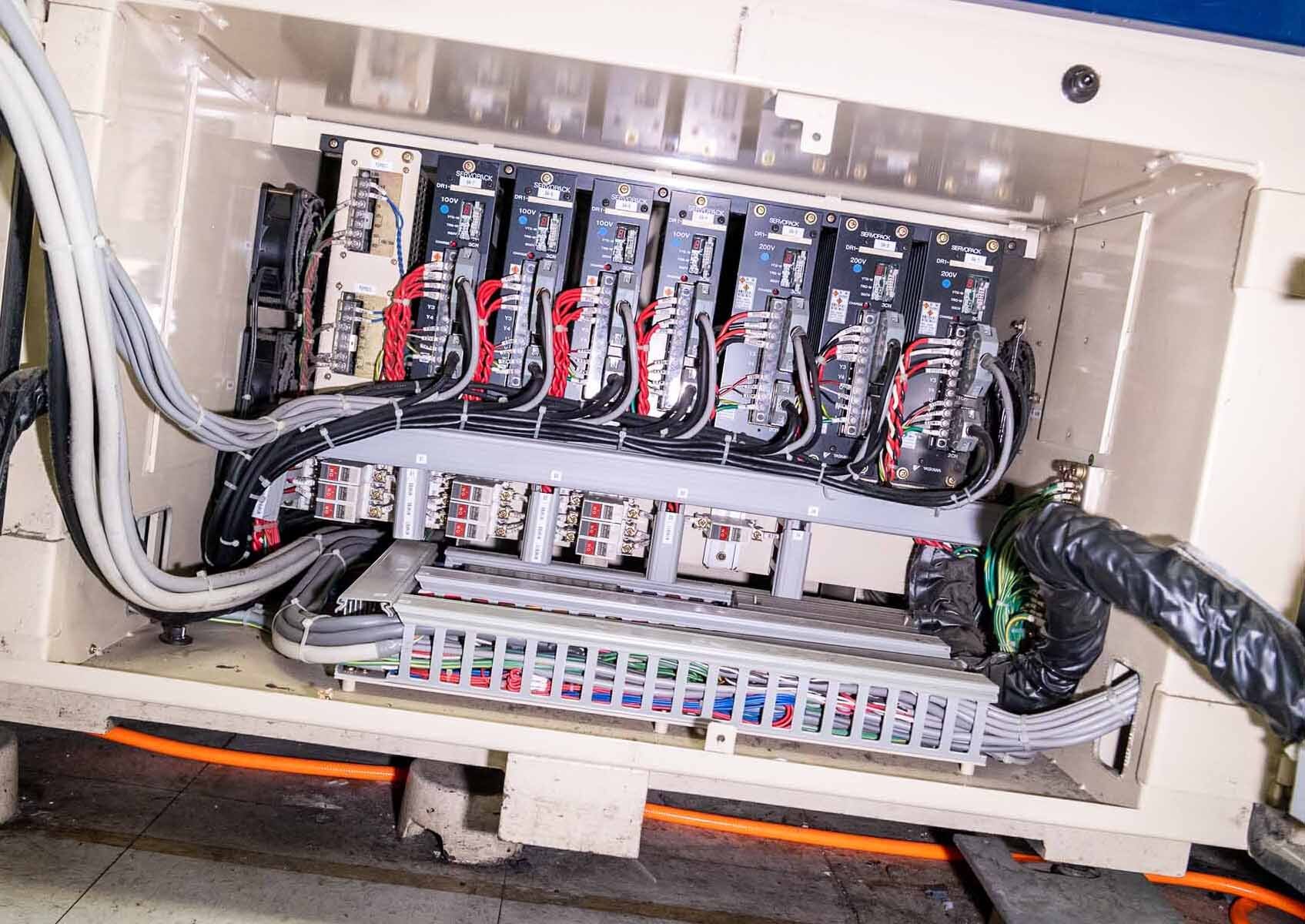

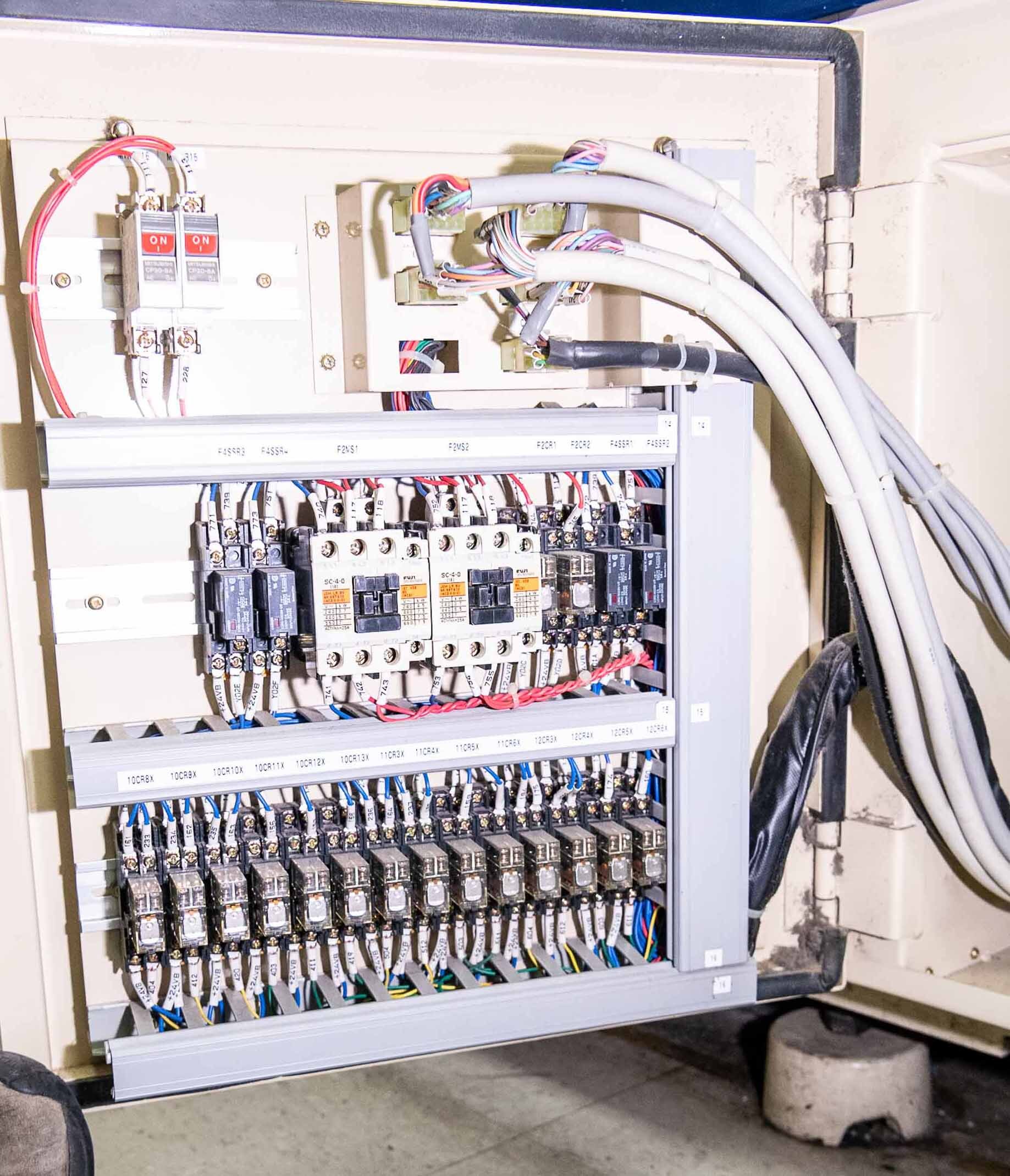

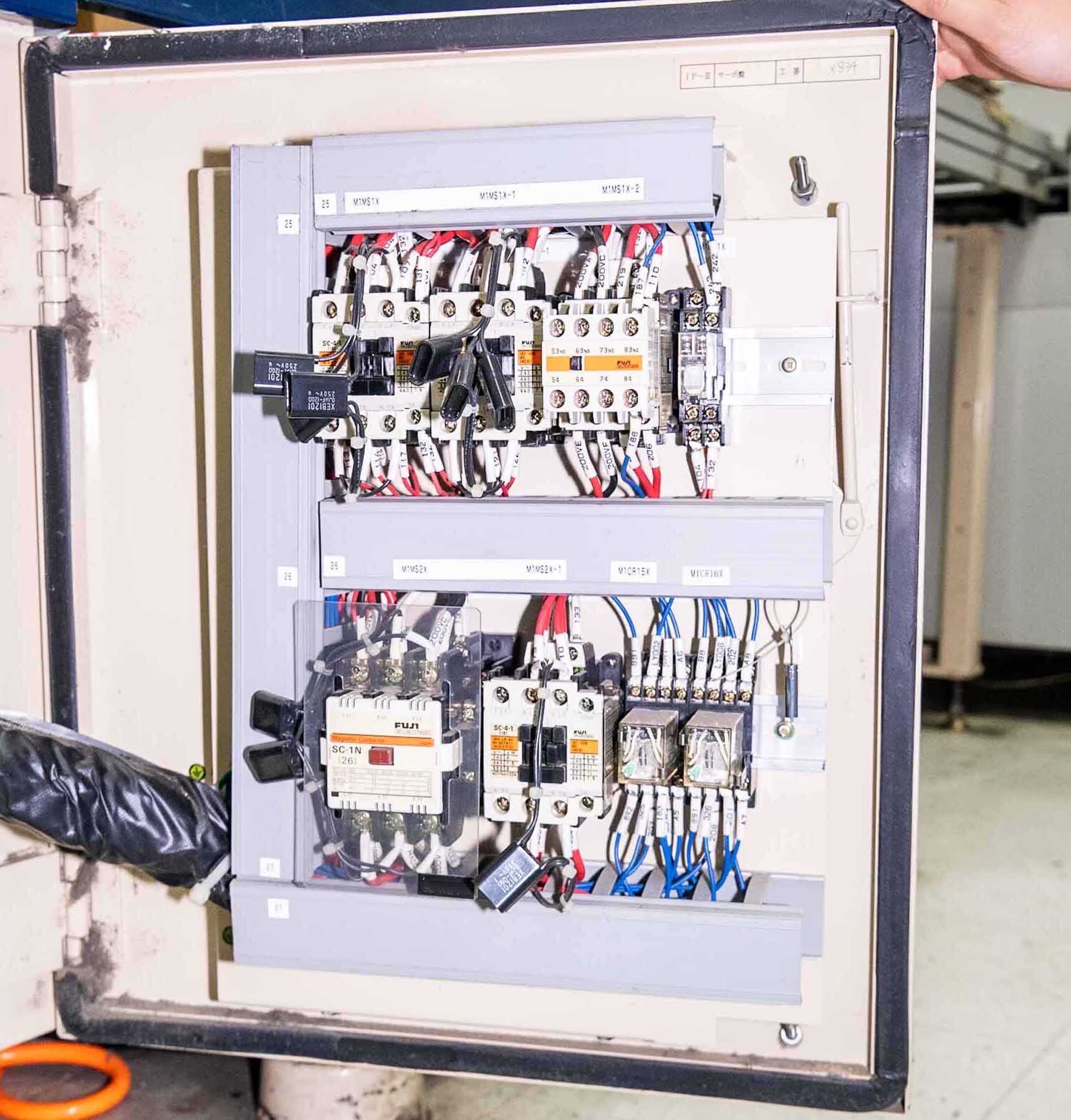

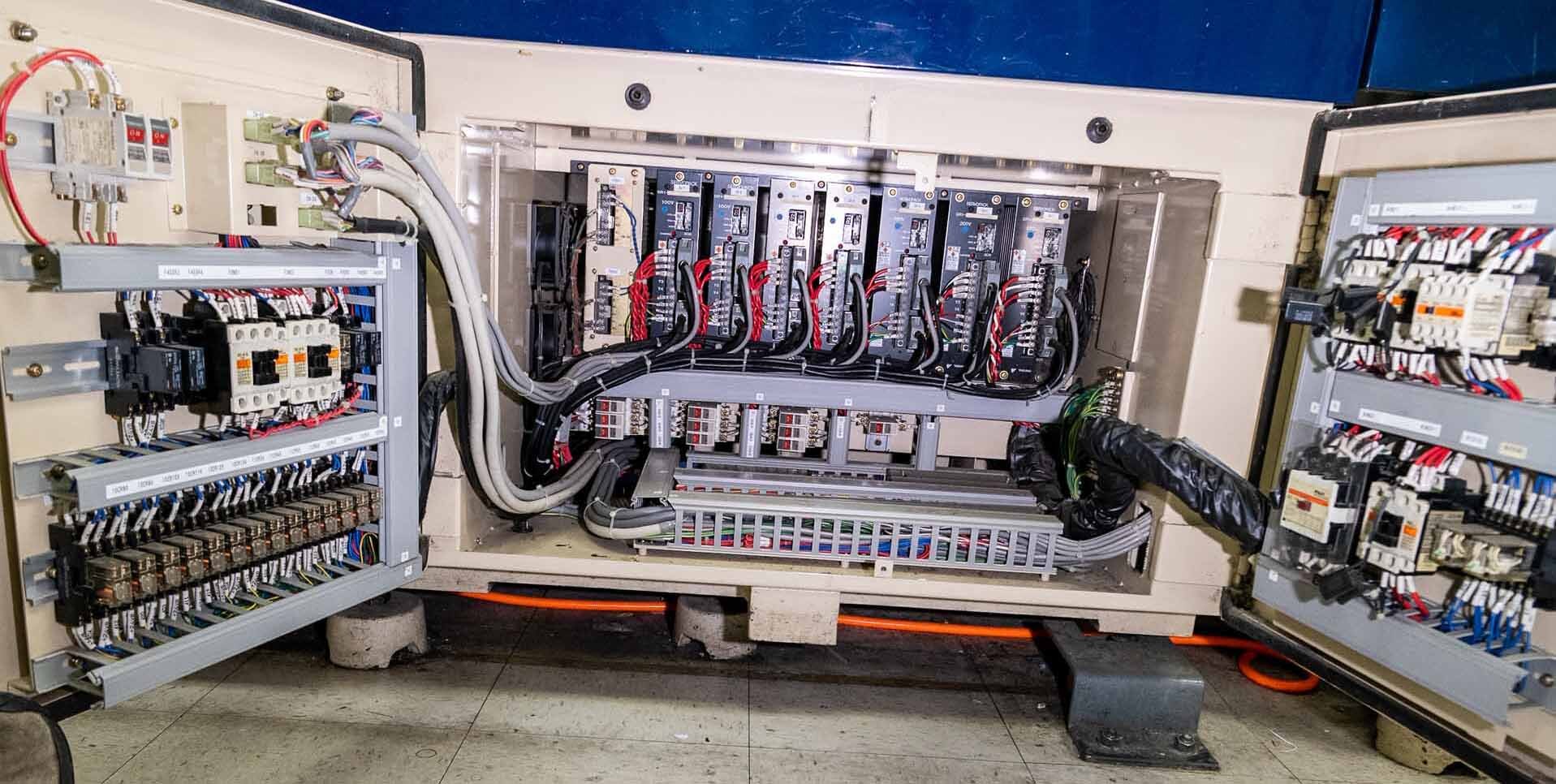

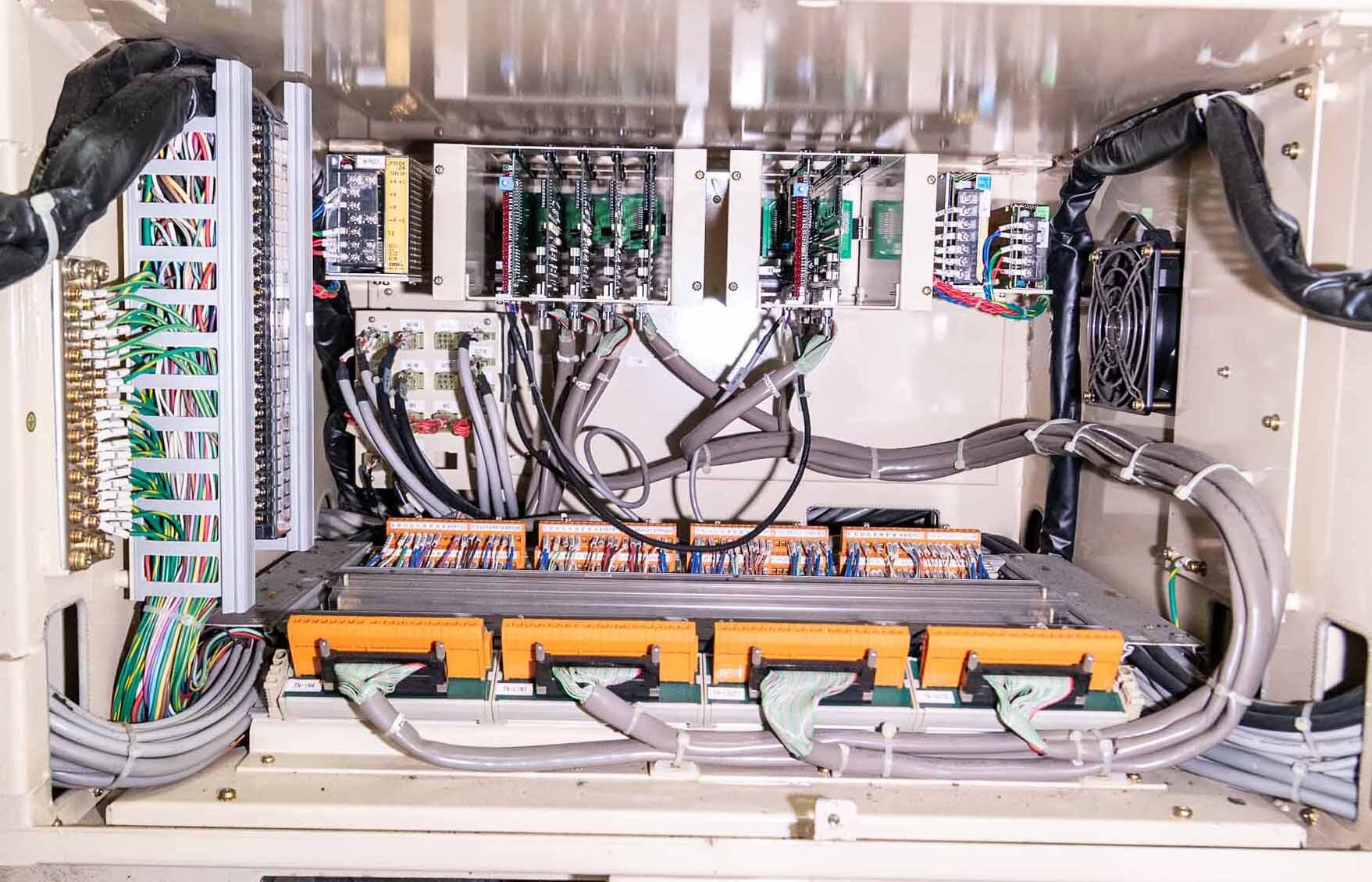

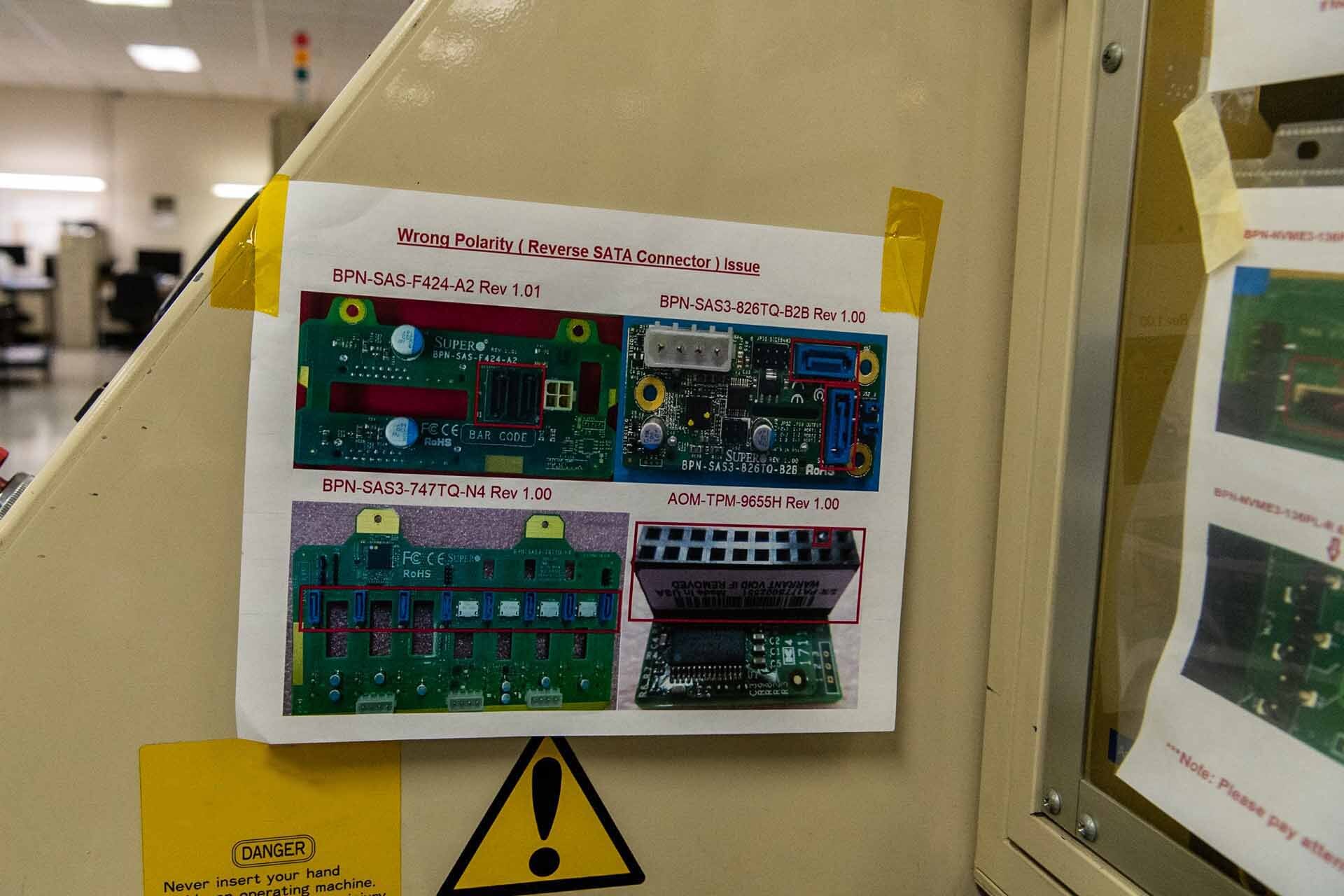

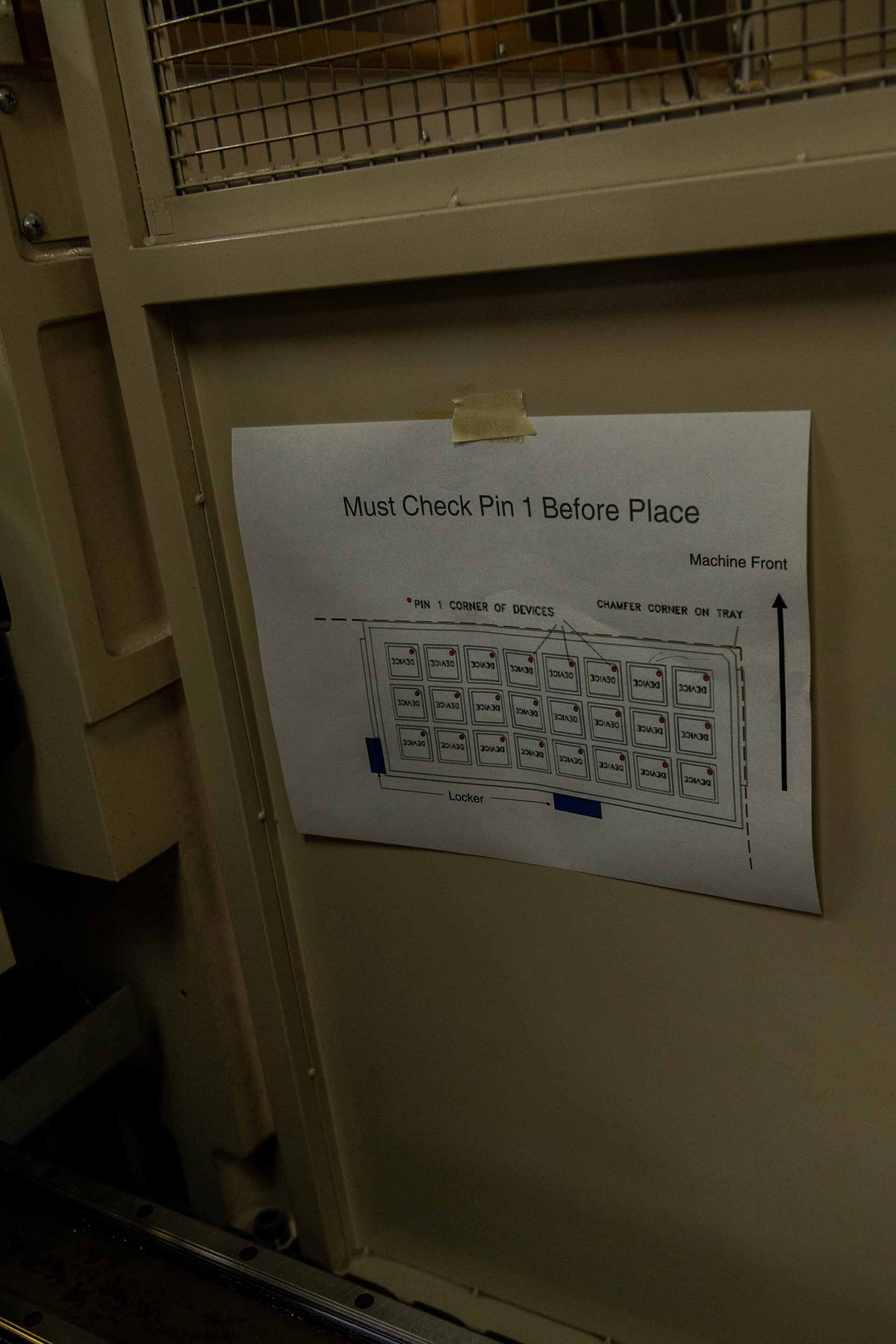

FUJI IP3 is an advanced PC board assembly and manufacturing equipment that is designed to meet the specific requirements of the modern electronics manufacturing industry. FUJI IP-3 is an intelligent workstation system based on the latest state-of-the-art FUJI technology, offering enhanced production efficiency. The unit itself is made up of several distinct components which include a programmable logic controller (PLC), a vision machine, an SD card reader, a conveyor belt, an automation tool, and a human machine interface (HMI). IP 3 PLC is a robust, highly efficient control center which is utilized to monitor and automate the PC board assembly and manufacturing process. The PLC integrates a wide range of inputs such as signals from sensors, feedback from actuators, and advanced programming to ensure efficient and productive operation. All of the asset's components, including the PLC, can be easily programmed to ensure consistency in operations and exact compliance with industry standards. The vision model is what makes FUJI IP 3 unique and one of the most advanced PC board assembly and manufacturing systems on the market today. This highly advanced vision equipment utilizes industry-leading vision technology to accurately scan parts and components during the production process, and with the help of sophisticated software is able to detect any anomalies or incorrect placements on the board. This prevents downtime and increases production efficiency. At the heart of IP-3 lies a versatile automation system which has been designed to cover all aspects of PC board assembly and manufacturing. This unit takes care of all transportation, identification, orientation, and fabrication of the parts and components required for board assembly as well as ensuring that the product produced is of high quality. The automation machine is also highly energy efficient and helps to reduce energy consumption during the production process. The SD card reader and conveyor belt are both integral parts of IP3. The SD card reader is used to read data from an SD card and this data can be used to upload product designs and part data and control the assembly process. The conveyor belt is used to transport the PC boards throughout the production line and is also able to handle a high-capacity workload. The human machine interface, or HMI, is an essential component of FUJI IP3. This tool provides a user-friendly interface which facilitates communication between users and the asset. The HMI makes it easy for users to control, monitor, and adjust the model's settings in order to get the most out of the equipment. FUJI IP-3 is an advanced PC board assembly and manufacturing system that offers enhanced performance and efficiency over traditional systems. With its easy-to-use controls, high- tech vision unit, and automation capabilities, IP 3 is a state of the art solution to the modern electronics manufacturing industry.

There are no reviews yet