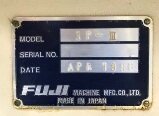

Used FUJI IP3 #9286007 for sale

URL successfully copied!

Tap to zoom

FUJI IP3 is a pc board assembly and manufacturing equipment specifically designed to meet the needs of today's board assembly and manufacturing operations. It features a high-speed SMT placement system, which allows for the placement of components with a maximum height of 0.8mm to the 12th layer of a board. The placement accuracy is +/- 25 microns. The unit is also capable of synchronizing both the motion and the insertion of components during placement. FUJI IP-3 offers a unique vision machine. It features real-time image processing technology which is used to detect, measure, and recognize components in order to ensure accurate placement. This feature provides high speed and accuracy as the tool can detect and recognize components in both real-time and offline mode. Additionally, it caries out fail/pass tests and height measurements with its vision asset. IP 3 also contains three main components. It houses an independent microprocessor which can be used to control the machine and manage data. The microprocessor can be connected to the centralized machine monitoring model. Additionally, a dedicated peripheral board is included with IP-3, which is used to connect and manage peripheral equipment. IP3 also features a precision assembly head. It is powered by a servo motor which provides a precise and reliable motion. FUJI IP 3 offers a sophisticated and reliable solution for board assembly and manufacturing operations. It allows users to rapidly and accurately assemble small to medium boards. The equipment is also capable of handling mid and large volume production with its high-speed SMT placement system and vision unit. Additionally, it is equipped with a wide range of supportive technologies such as offline programming, collision detection, and automatic scheduler, in order to maximize production efficiency.

There are no reviews yet