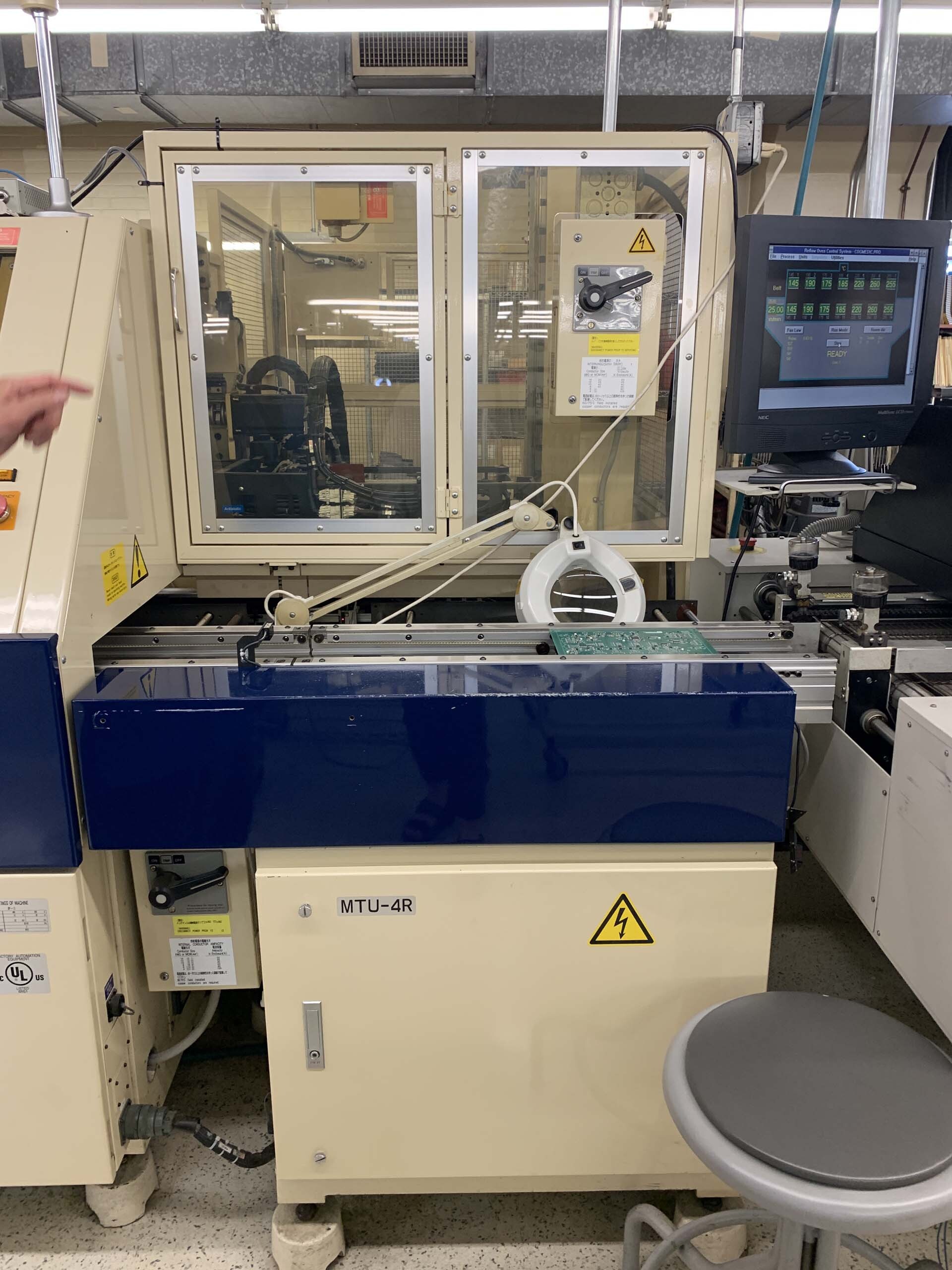

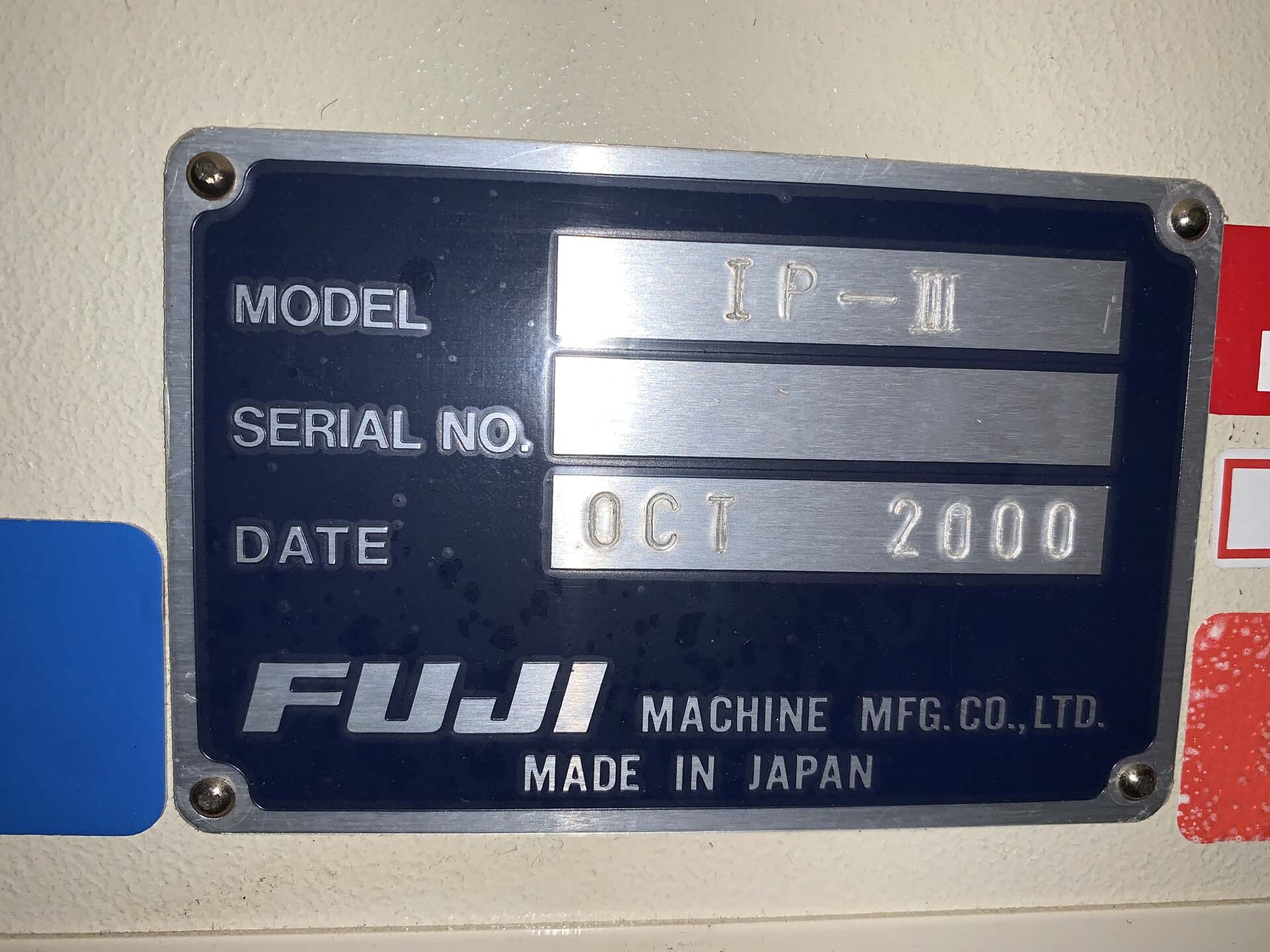

Used FUJI IP3 #9394730 for sale

URL successfully copied!

Tap to zoom

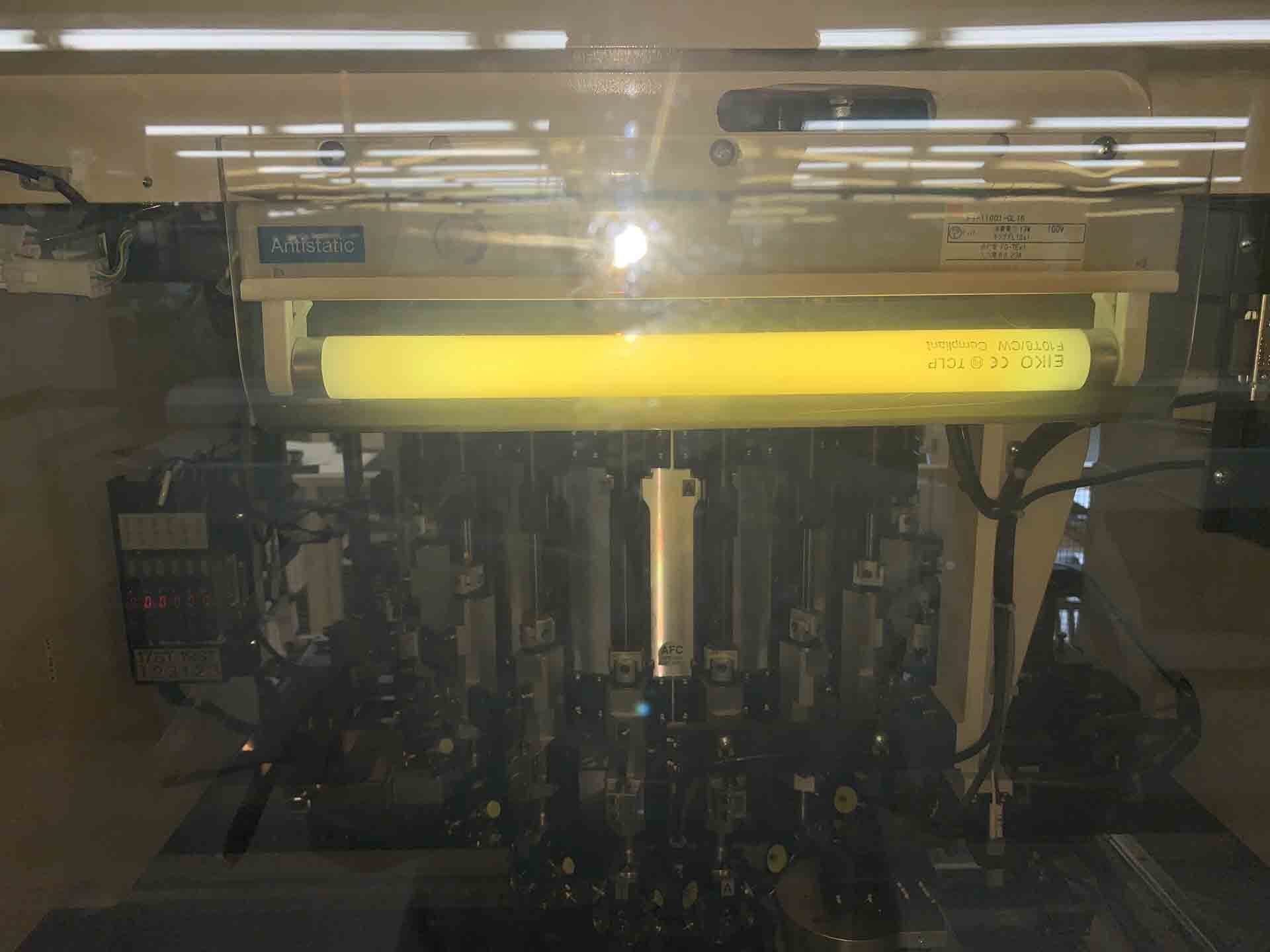

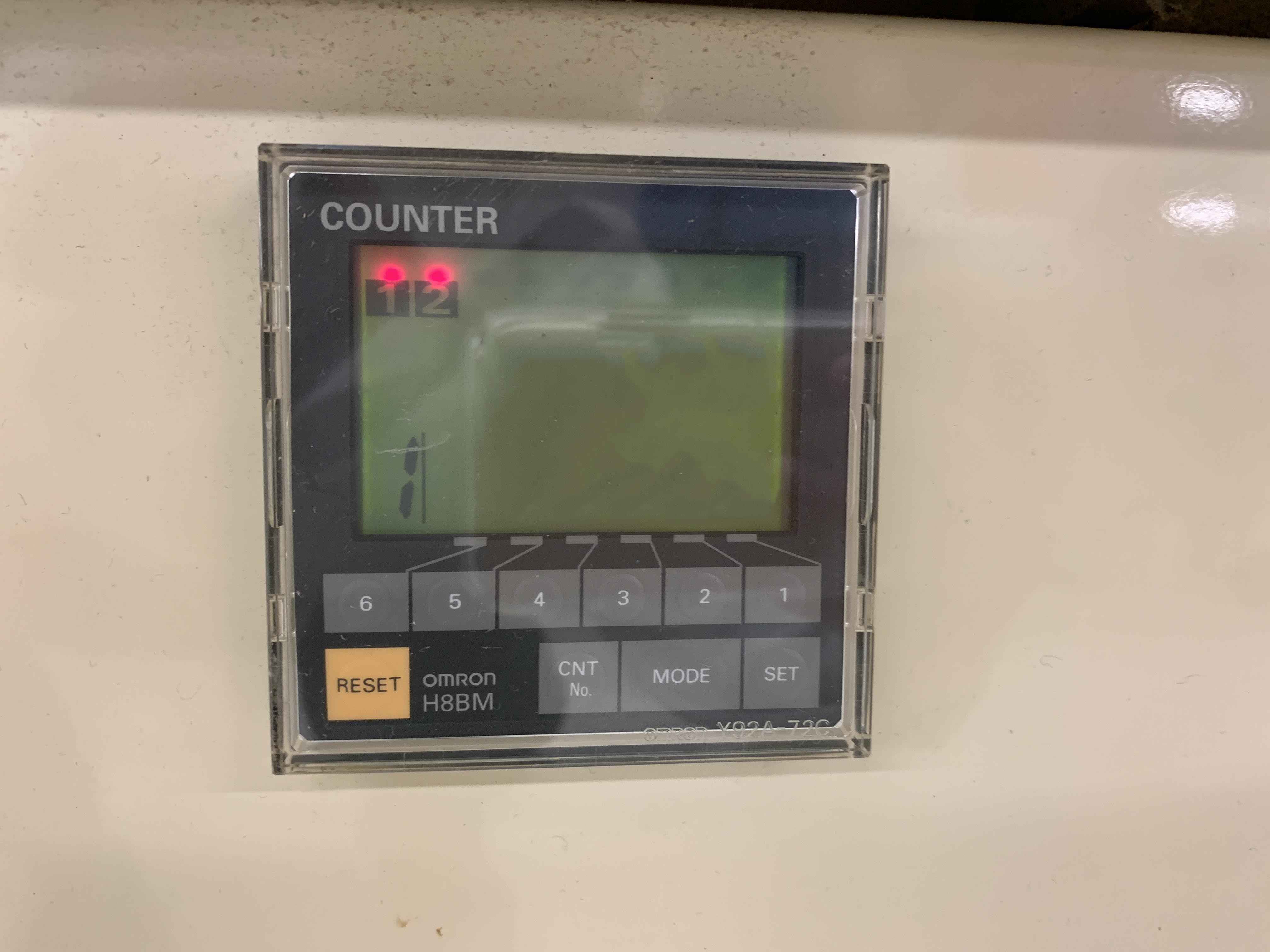

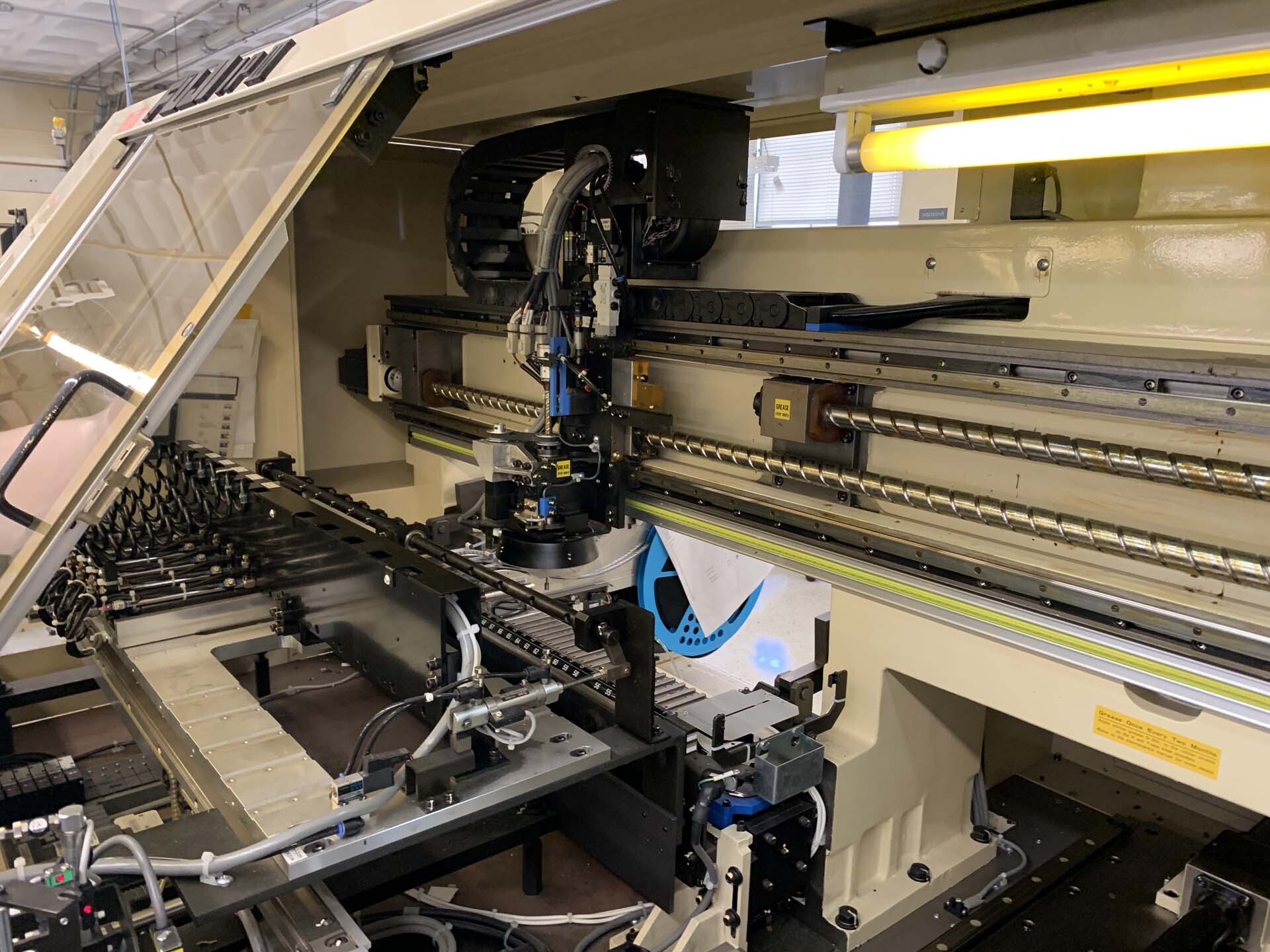

FUJI IP3 (Integrated Production Platform 3) is a complete, self-contained PC board assembly and manufacturing solution. It is designed to provide maximum efficiency, process and production control for modern electronics production, delivering a cost-effective alternative to manual assembly. FUJI IP-3 can be configured to include all of the necessary components for automated PC board assembly, including: 1. Automated optical inspection equipment (AOI) for verifying placement correctness. 2. Component placement machine (CPM) which can accurately place a wide variety of surface mount components. 3. Soldering machine (SM) for soldering components onto the board. 4. Pick & place machine (PPM) for integration with the advanced printing technologies of FUJI for high-precision component placement. 5. 3D solder paste inspection (SPI) for ensuring that the soldering paste application is correct. 6. Bus bar processing system (BBP) for performing treatments to bus bars, such as cutting, bonding and routing. 7. And finally, rework station (RS) for correcting minor manufacturing defects prior to shipment. In addition to these automated systems, IP 3 unit can also include thermal profiling and measurement systems, laser depaneling systems and BGA reballing systems to provide the fullest, most cost-effective end-to-end PC board assembly and manufacturing solution. IP-3 is designed with flexibility in mind, allowing for integration of multiple systems into a single unit for maximum efficiency. It also has an integrated PC server which can store production data and track production over time, allowing for consistent and reliable production. The machine is additionally intelligently designed to provide clear alarms and tool status notifications to ensure that any negative issues can be addressed quickly and efficiently, minimizing product damage and minimizing wastage. FUJI IP 3 platform is highly intelligent and capable, allowing users to achieve high levels of accuracy and efficiency in assembly, delivering the highest quality output. With automated component placement and inspection, automated solder paste inspection and related assembly processes, and centralized control over production data, IP3 provides a complete, optimized PC board assembly and manufacturing solution for modern production requirements.

There are no reviews yet