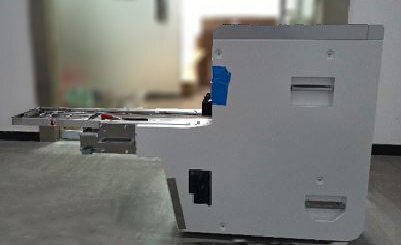

Used FUJI M-Tray unit for NXT #9378919 for sale

URL successfully copied!

Tap to zoom

ID: 9378919

FUJI M-Tray is an automated PC board assembly and manufacturing equipment designed for quick and efficient production of printed circuit boards. The system consists of four main parts: a control panel, an assembly tray, a motherboard assembly conveyor, and a rework station. The control panel features a user-friendly interface that allows the operator to move, set, and monitor all production parameters for the unit. It also allows the operator to easily monitor and manage the machine's assembly tray inventory as well as to monitor tool operations and to make any necessary adjustments. The assembly tray is a stationary container designed to accommodate multiple printed circuit boards. It ensures that the PCBs remain in position while they are picked by automated robotic arms. The tray also minimizes residue left on the PCB during automated assembly. The motherboard assembly conveyor is a continuous-feed assembly line designed to transport PCBs from the assembly tray to a rework station. It can hold and move PCBs in increments of 0.2 mm. It also ensures consistency and accuracy during assembly by providing a level platform for the robotic arms to place components on the PCBs. The rework station is the final component of FUJI M-Tray. It is used to insert components into the printed circuit board and to perform rework operations, such as repairing or replacing damaged components on the circuit boards. This station also holds the PCBs in place and ensures that the assembly process is consistent and accurate. FUJI M-Tray is a highly efficient asset for automated assemblies and rework of printed circuit boards. It is easy to use, due to its user-friendly interface and can be quickly set up and operated. The model ensures that the assembly operation is accurate and efficient, and it is a productive and reliable solution for increasing production output.

There are no reviews yet