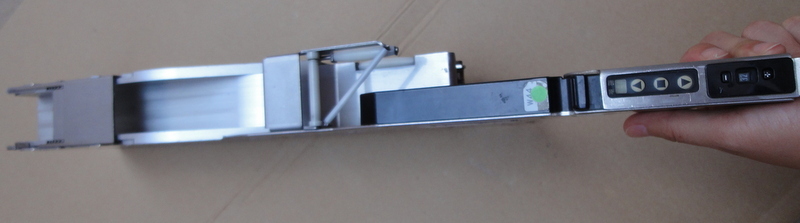

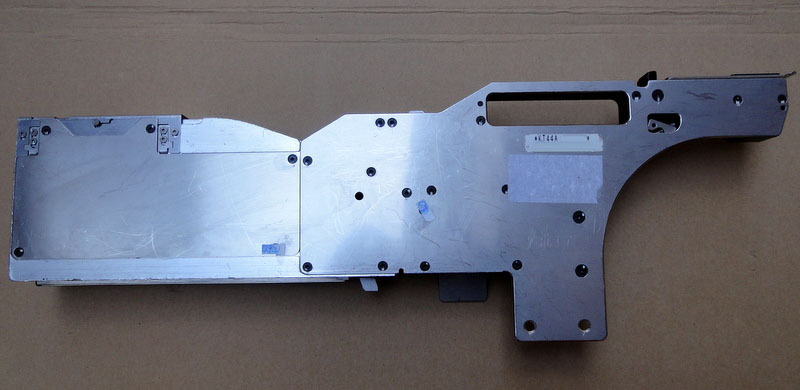

Used FUJI NXT I #199510 for sale

URL successfully copied!

Tap to zoom

FUJI NXT I is a fully automated production line for pc board manufacturing and assembly. The equipment is comprised of several integrated machines that function together to assemble the pc board. The line consists of a surface mount technology (SMT) machine, an automated optical inspection (AOI) machine, a reflow oven, an automatic tool changer, and a selective soldering system. The SMT machine is used to place surface mount components onto the board. It uses a pick-and-place head to accurately and quickly place components of various shapes and sizes onto the board. The AOI machine is used to inspect each component placed on the board, looking for soldering flaws and excess flux. The reflow oven melts the solder paste on the board to permanently connect the components. The automatic tool changer allows for the use of different tools, such as curing tools, heat guns, and nozzles, depending on the kind of component being worked with. The selective soldering unit is used to apply solder to the through-hole components. FUJI NXTI is capable of handling a wide range of pc board sizes and designs. It is controlled by an advanced pc-based controller, which is used to input the necessary instructions and settings for the various machines used in the process. It also includes a real-time monitoring machine that tracks the progress of the production line and can alert operators to any potential problems. The entire tool is highly reliable and efficient, producing finished pc boards of superior quality. Additionally, NXT-I can be easily upgraded and integrated with newer technologies, making it an ideal platform for manufacturers who need maximum flexibility. Its simple and intuitive user interface also makes it easy to master and operate, even by inexperienced staff. With its robust build quality and powerful set of features, NXTI is the perfect pc board manufacturing and assembly asset for any serious pc manufacturing operation.

There are no reviews yet