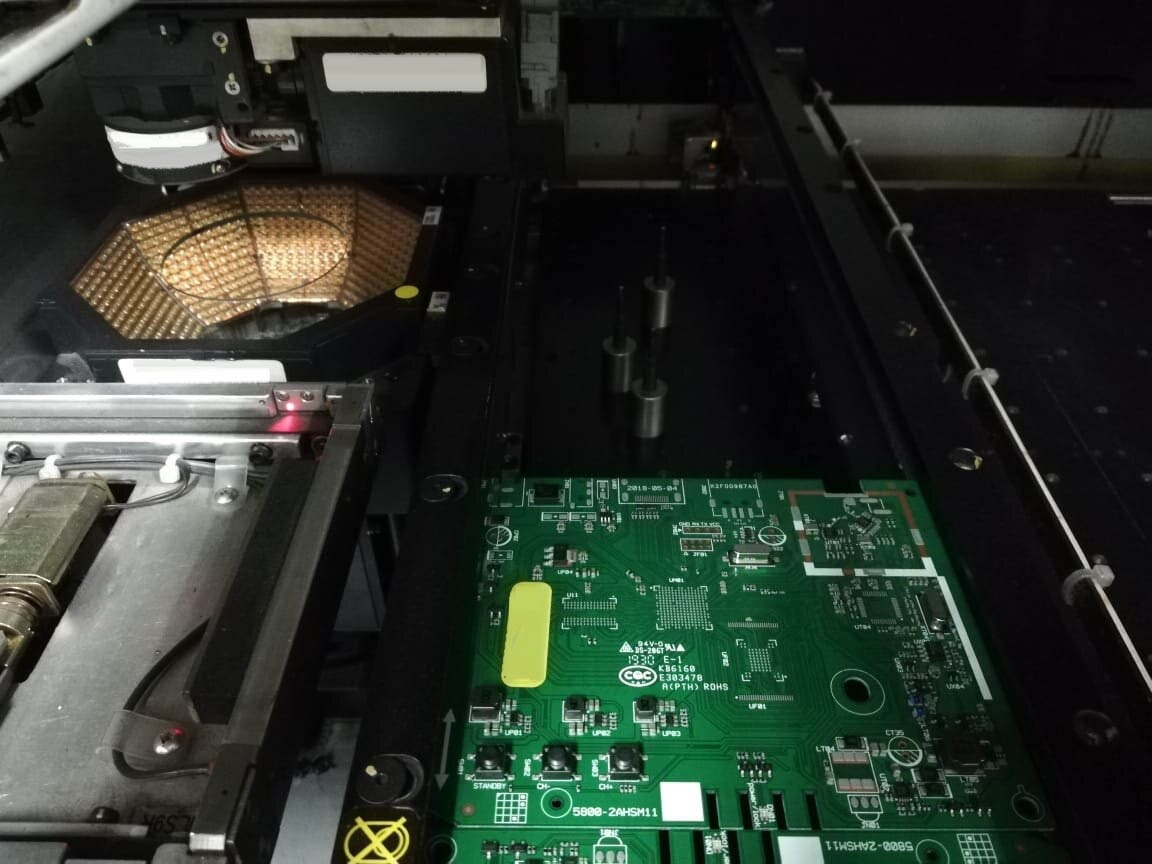

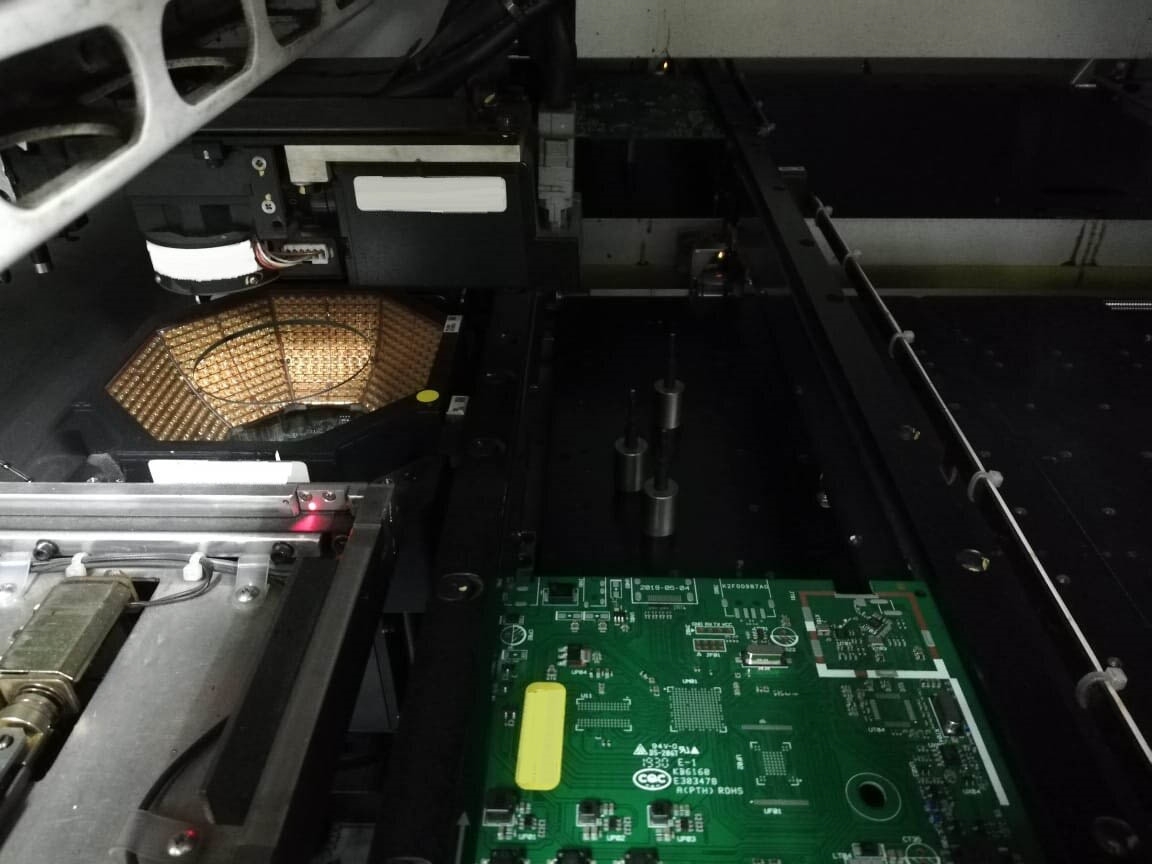

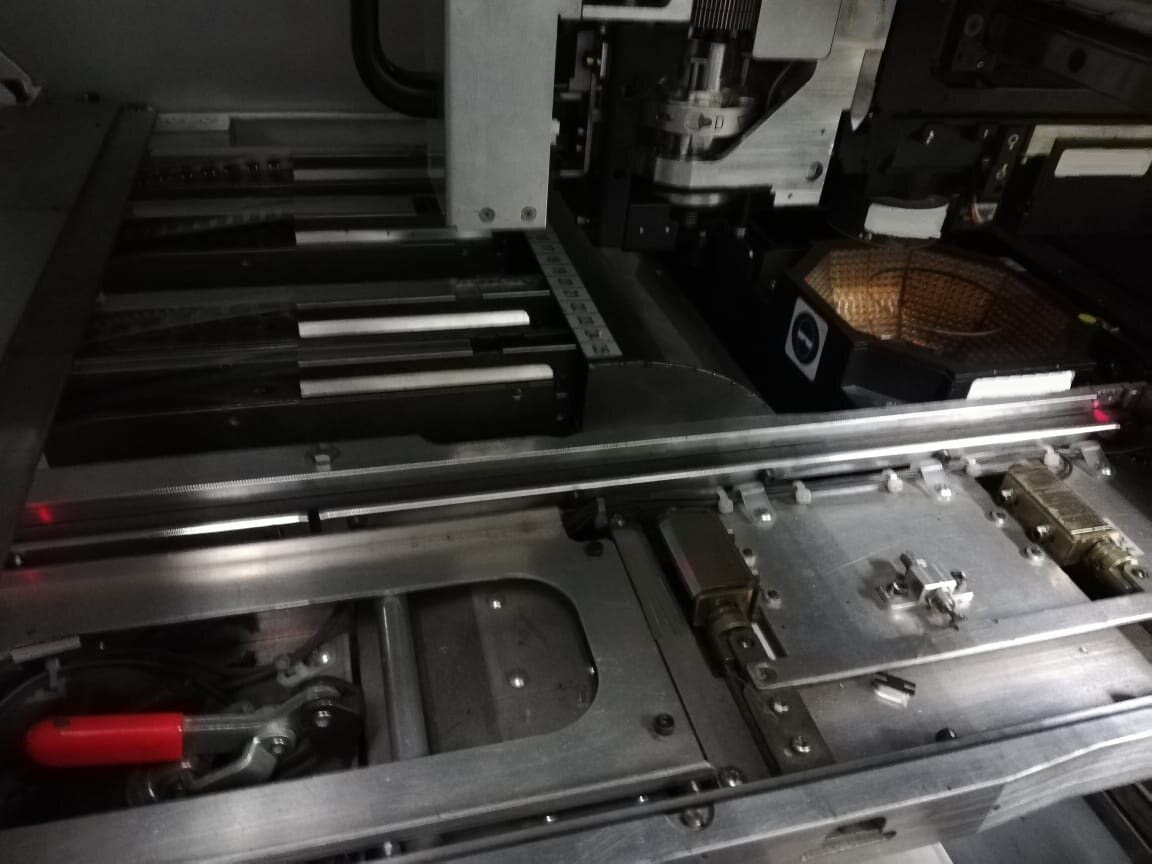

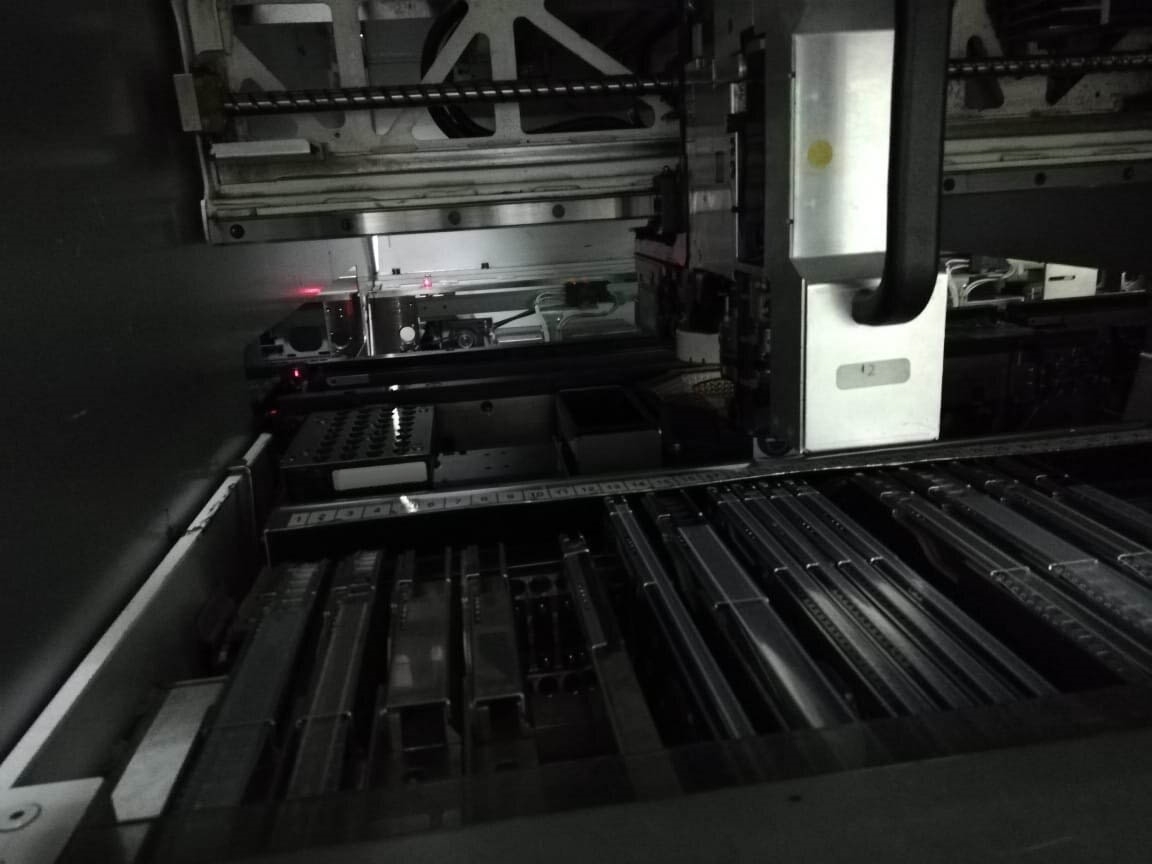

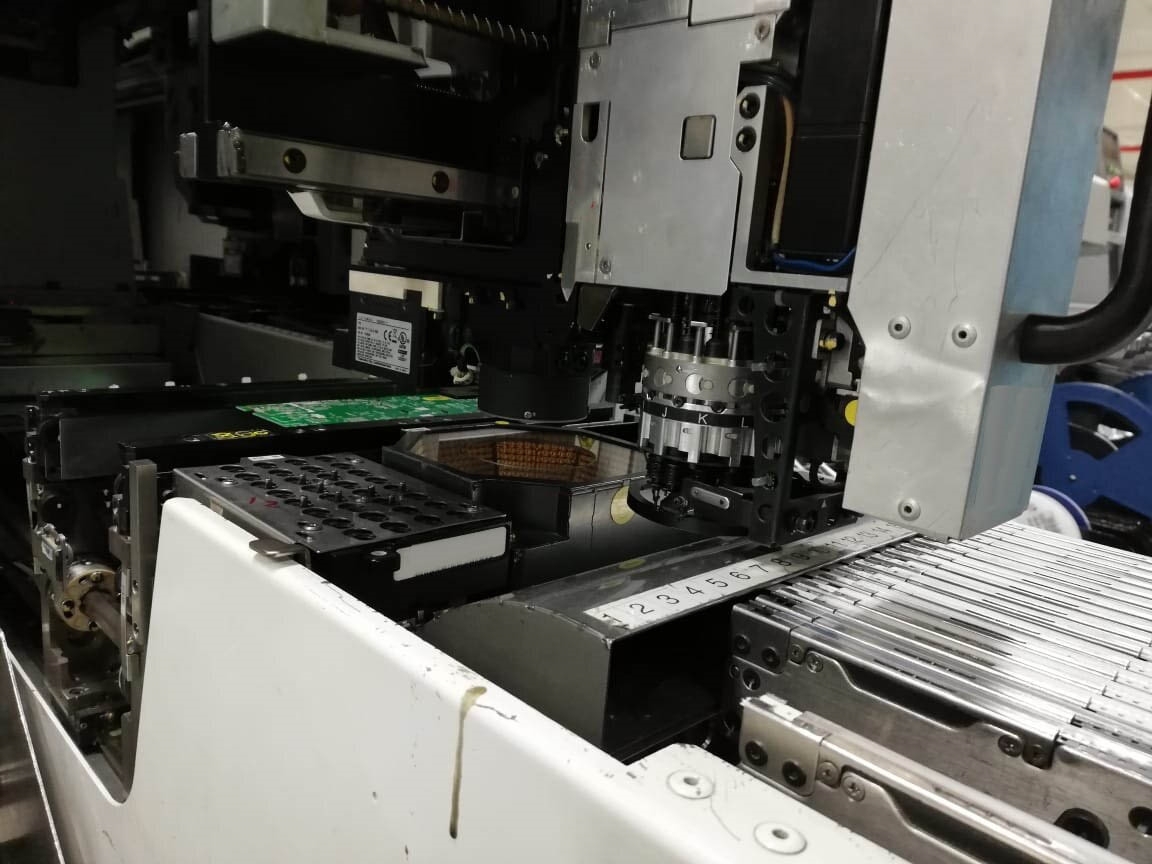

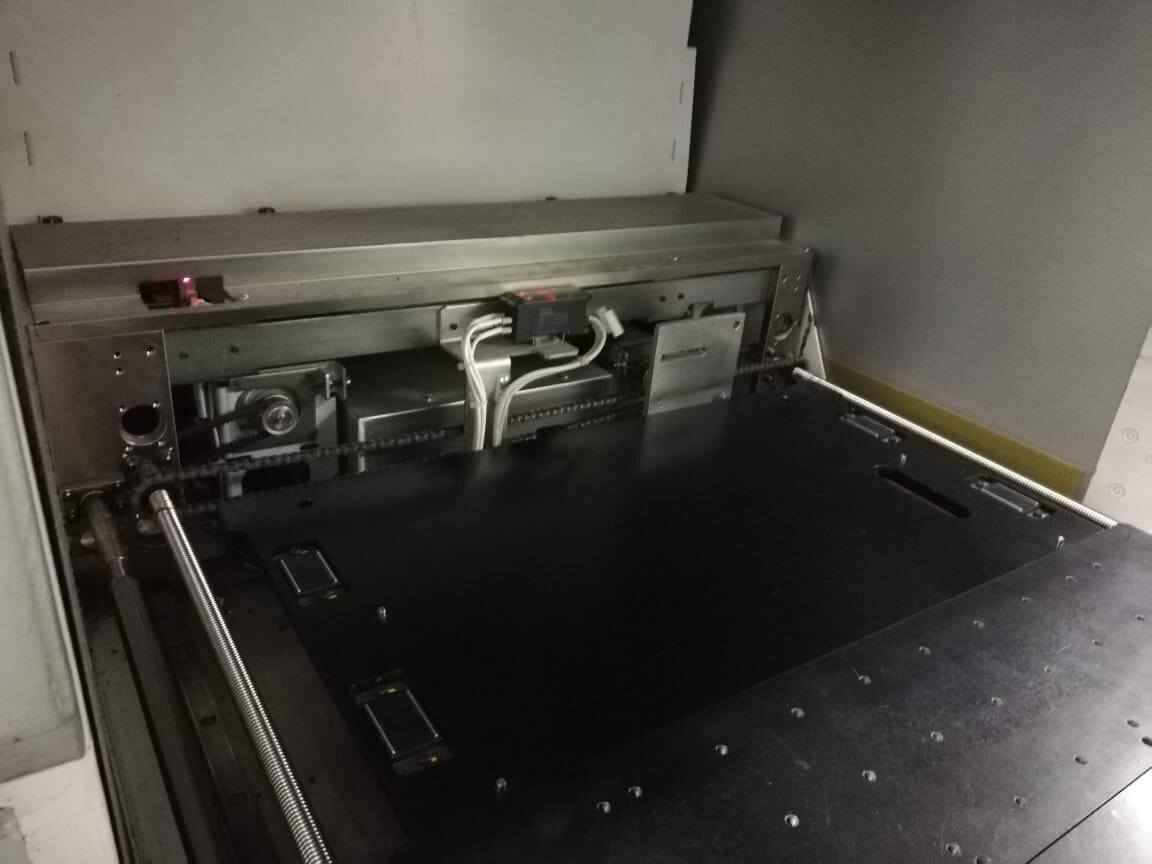

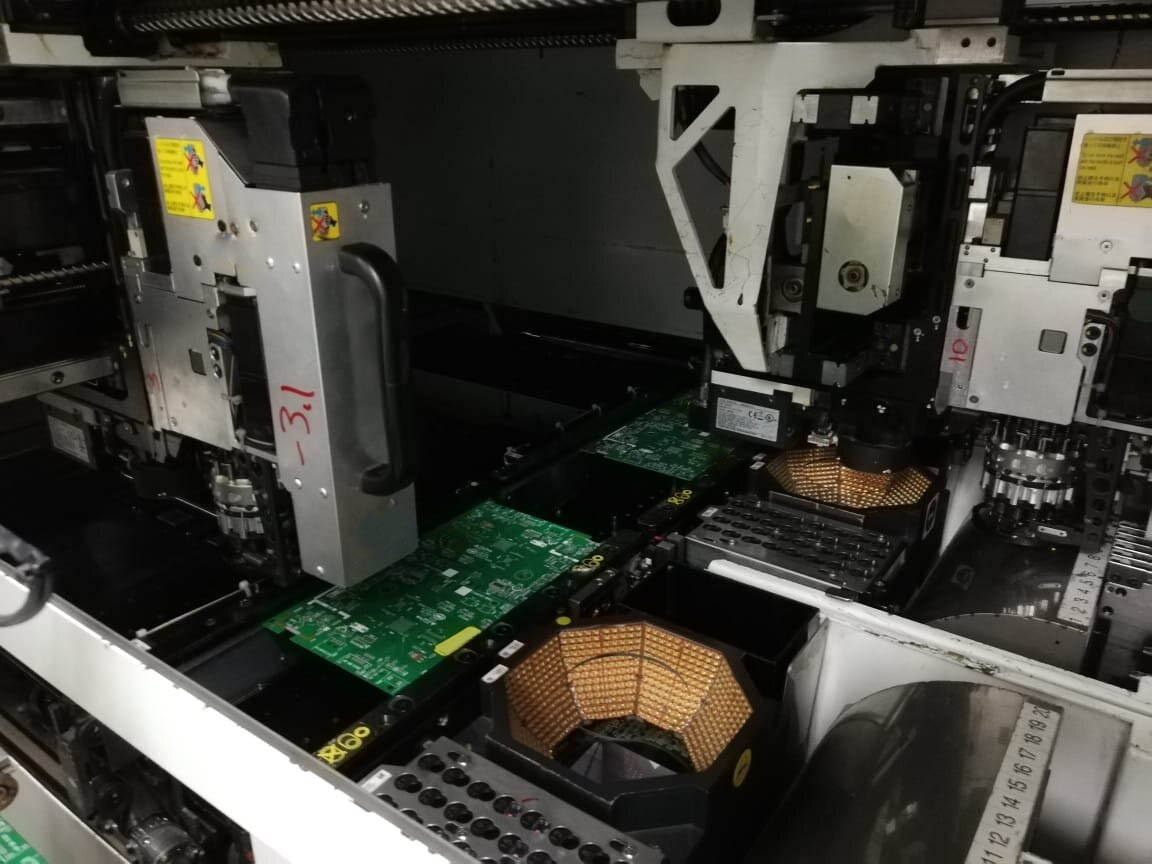

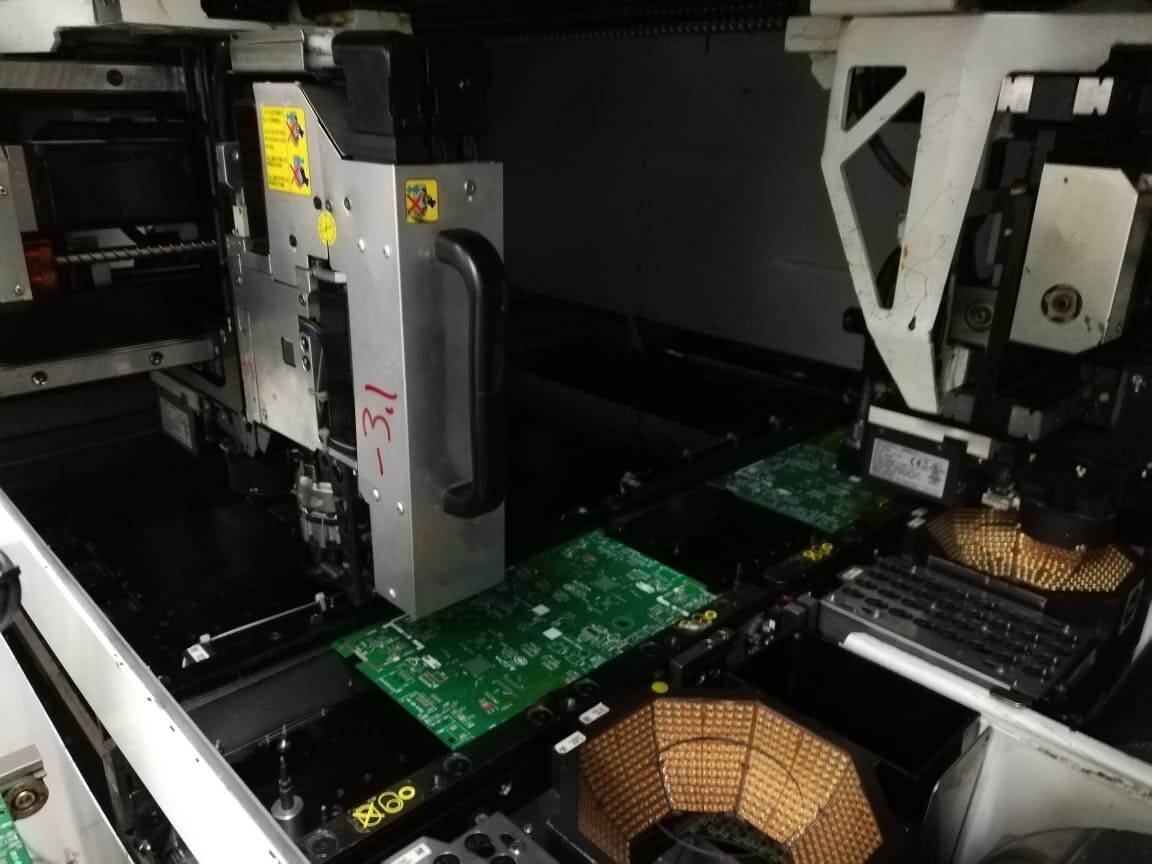

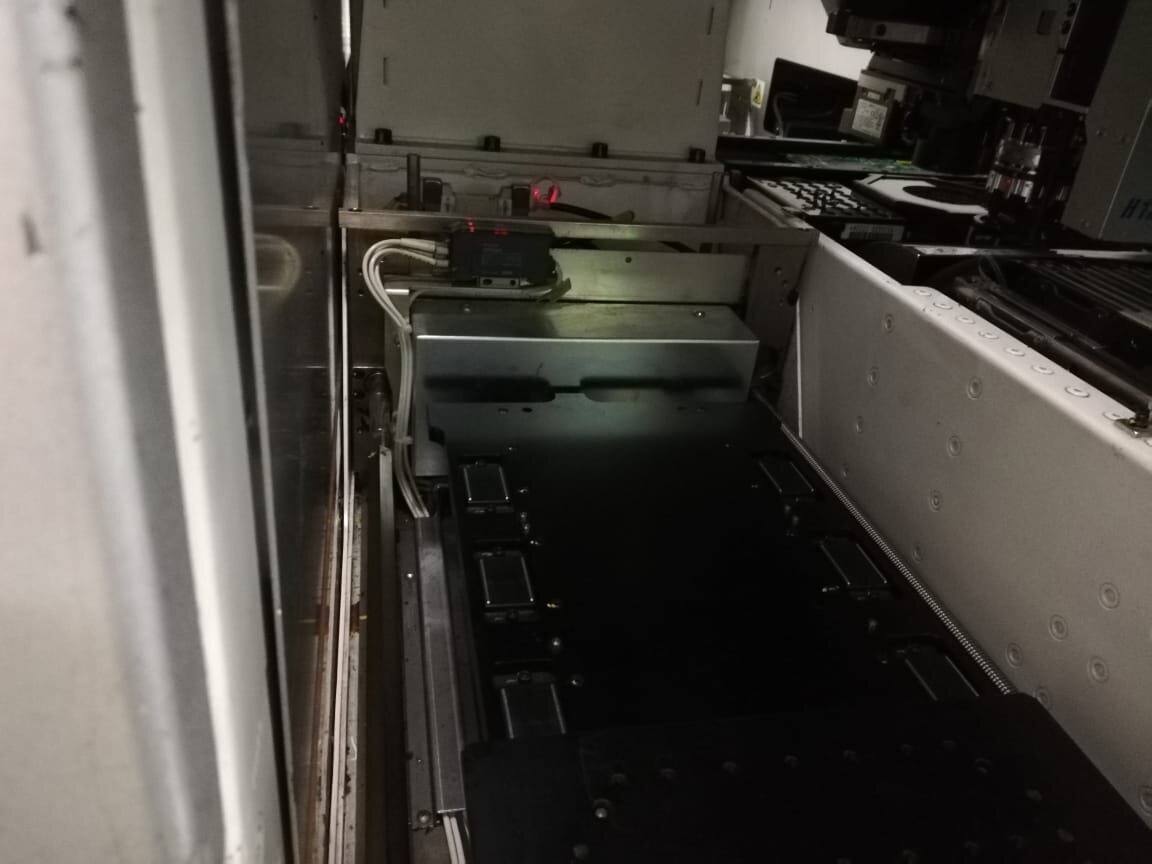

Used FUJI NXT I #9254065 for sale

URL successfully copied!

Tap to zoom

ID: 9254065

Vintage: 2007

Pick and place machine

(15) Modules:

(12) M3 Modules

(3) M6 Modules

Heads:

(14) H12S Heads

(3) H08 Heads

(2) H04 Heads

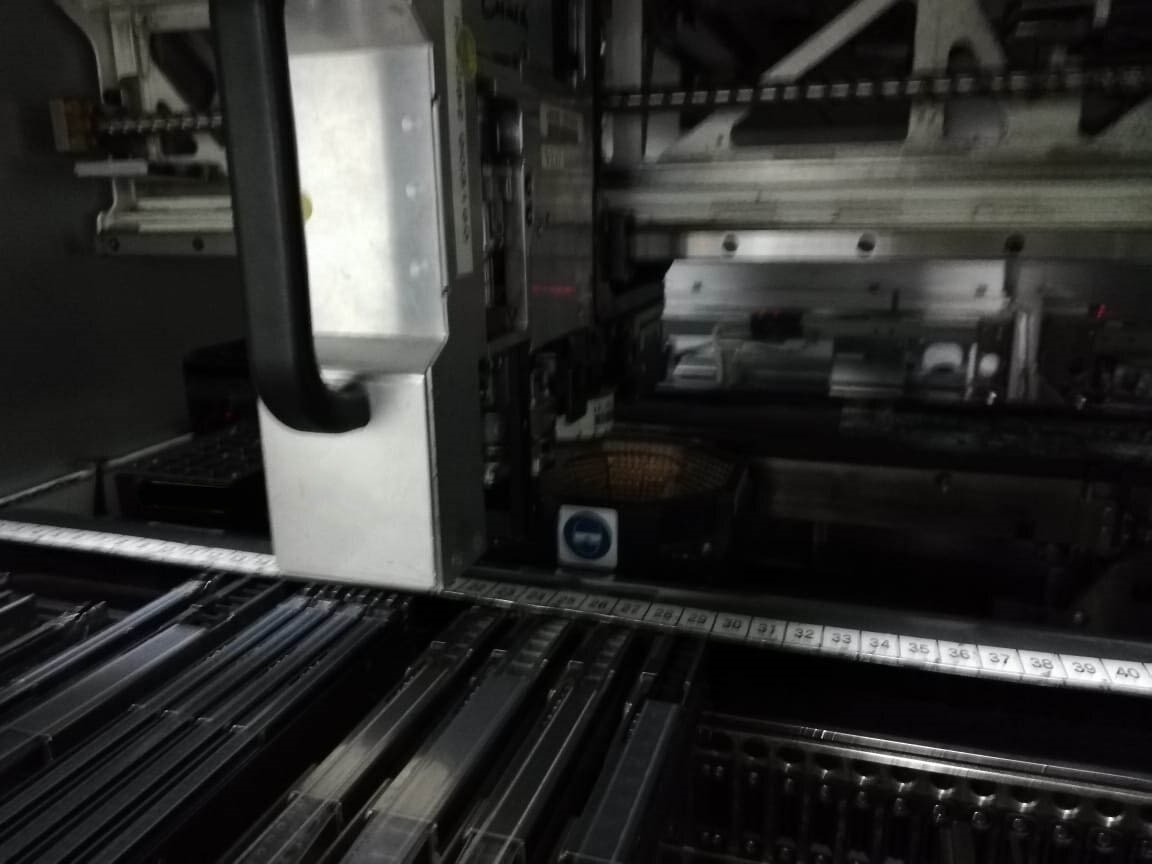

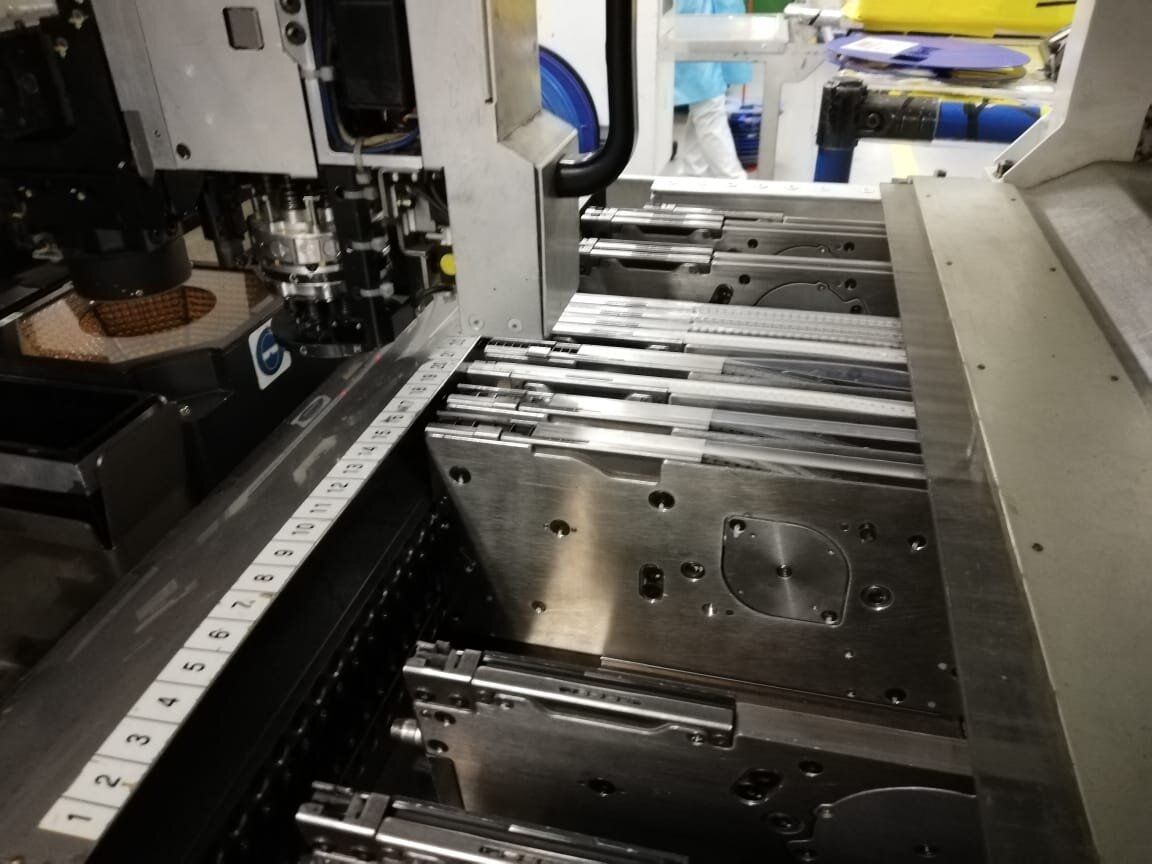

Feeders:

(379) 8 mm

(67) 12 mm

(27) 16 mm

(12) 32 mm

(10) 44 mm

(3) 56 mm

Feeder pallets:

(10) M3

M6

Feeder racks: (7) Trolley racks

Base 1:

Running hours: 66,581.2

Base 2:

Running hours: 67,674.4

Base 3:

Running hours: 66,902.3

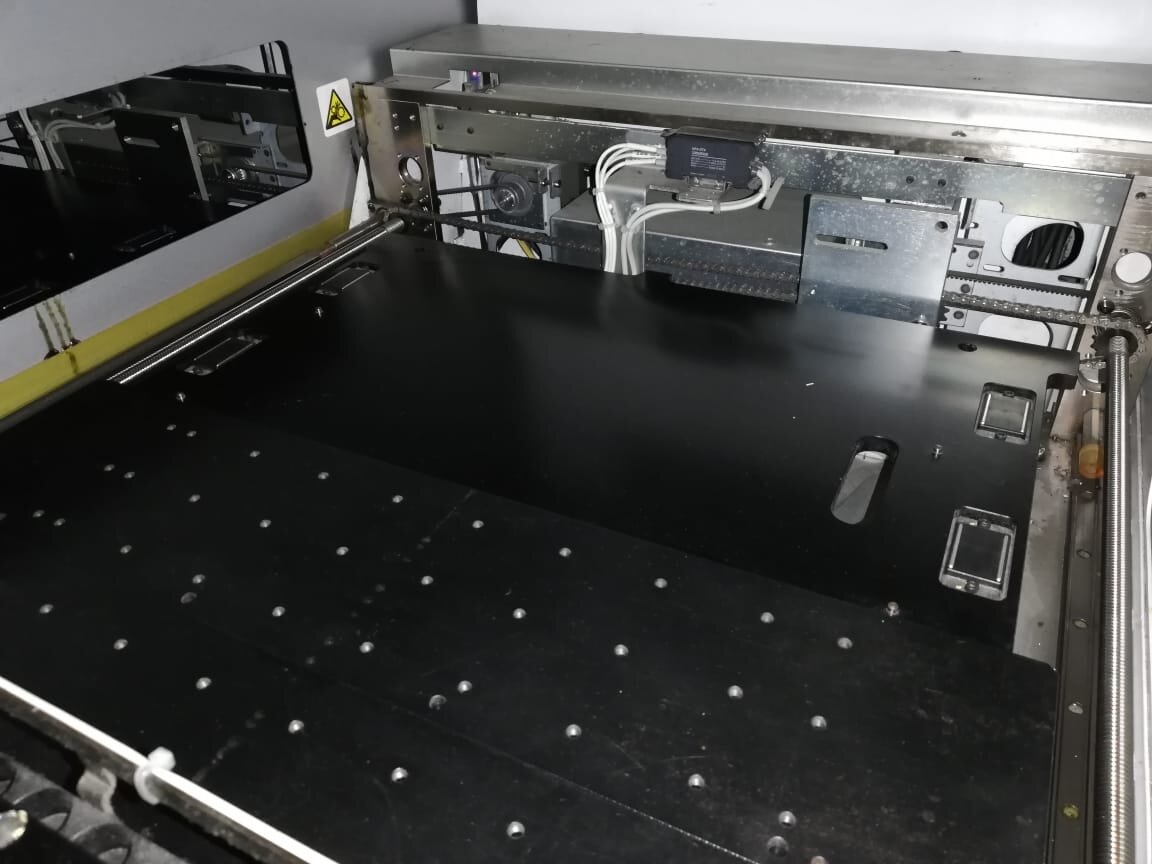

VPD System

LT Tray unit

2007 vintage.

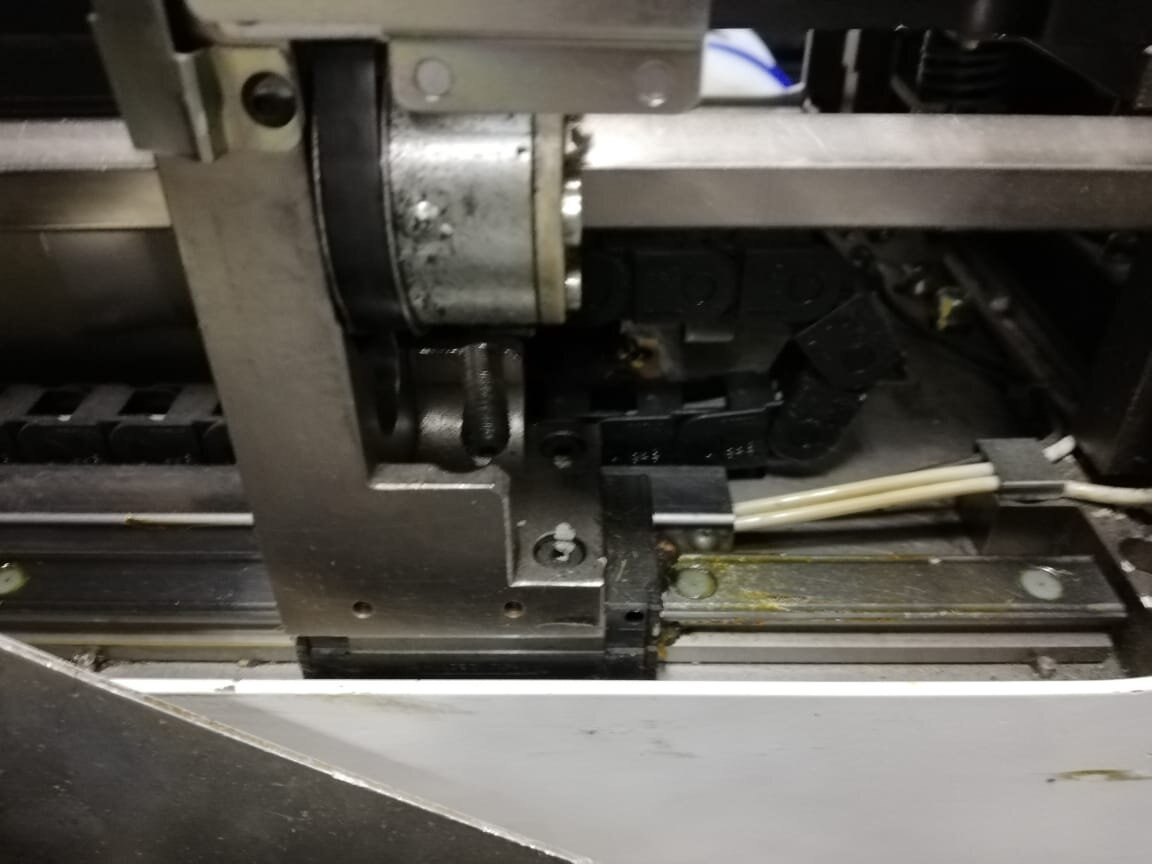

FUJI NXT I is an automated PC board assembly and manufacturing equipment designed to provide improved visual annotations and accuracy for faster, high-quality PCB assembly. It is designed to maximize efficiency by delivering both speed and accuracy while minimizing the number of components or steps required in the manufacturing process. FUJI NXTI is equipped with dual four spindle robots and automated optical image recognition, which combined with advanced vision technology allows quick identification of component positions and accuracy checks. With an internal conveyor belt to move PCB boards from station to station and a centrally located tool magazine with high capacity storage, NXT-I is able to quickly and accurately move components to the required position on the board and reduce cycle time. Additionally, the system features a built-in Wave Solder and Reflow unit which allows for easy integration into existing production lines. NXT I automates the entire process of PCB assembly, which begins with the delivery of raw materials such as PCB boards, components and solder paste. Once these materials are loaded, they are directed to the pick and place head and loaded onto the racks, where they are then loaded onto the conveyor. The built-in vision machine then locates the component on the board and places the component into the exact position with extreme accuracy. The accuracy of the placement is further ensured by the patented "Marking Check" function which determines whether or not the component is correctly placed. NXTI then marks the component for soldering with either a hot gas nozzle crimp or soldering with a built-in wave soldering or reflow unit. Once the board is loaded with components, the board is then moved through the soldering process to ensure a high-quality solder joint. FUJI NXT-I also offers integrated support for electronic code-reading, such as bar codes and RFID tags, which can further ensure accuracy, reduce manufacturing costs and increase efficiency. Finally, FUJI NXT I offers several quality assurance features and functions to confirm the accuracy of each board. The dynamic high-speed visual inspection tool performs high precision tests including reviewing component types and marking, excess solder removal, bridge integrity, and other checking functions. FUJI NXTI is also able to yield reports including quality status and any detected defects, which can be beneficial for keeping quality control records. In summary, NXT-I is a complete PC board assembly and manufacturing solution which provides quick and accurate automatic component loading, marking, placement, and soldering, as well as a range of quality assurance features and reporting capabilities. The speed and accuracy of the asset coupled with its support for barcode and RFID reading makes it an ideal choice for quality-focused PCB manufacturers.

There are no reviews yet