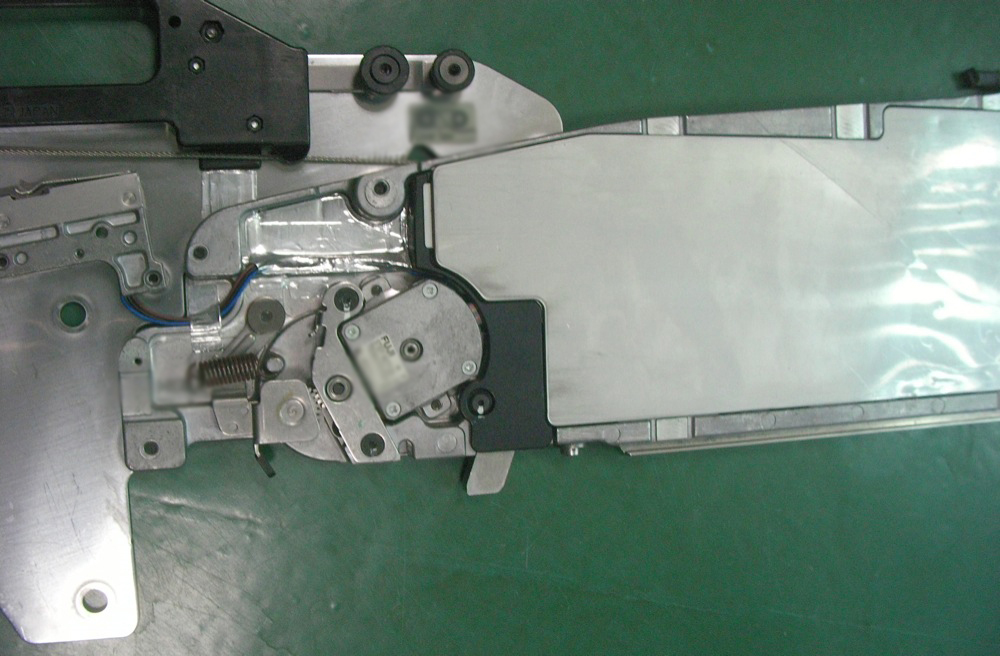

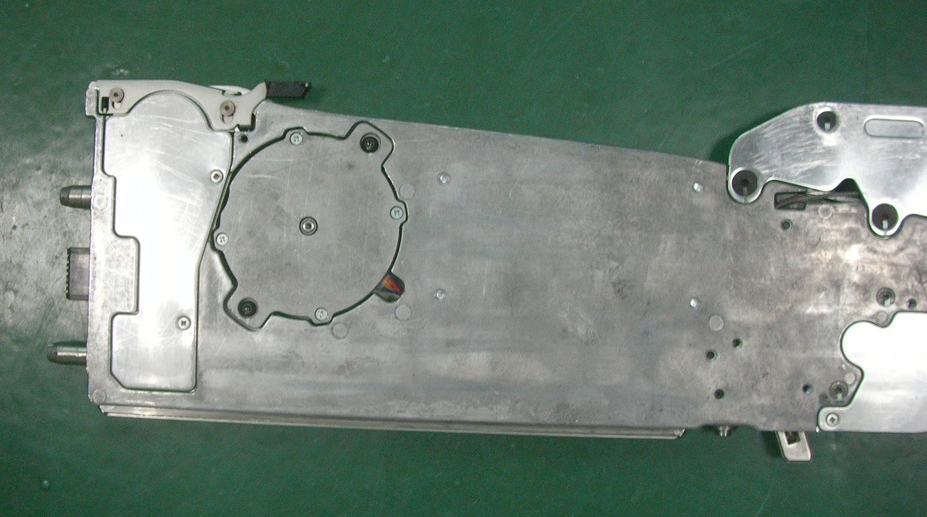

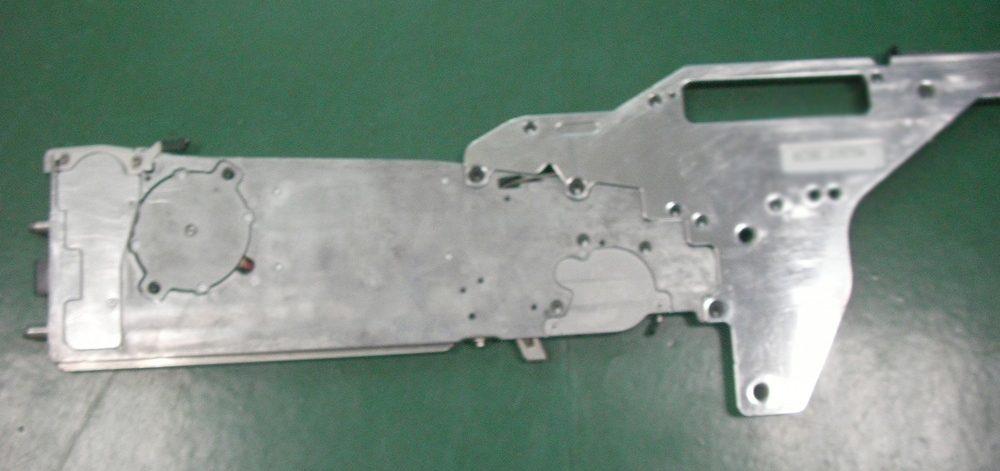

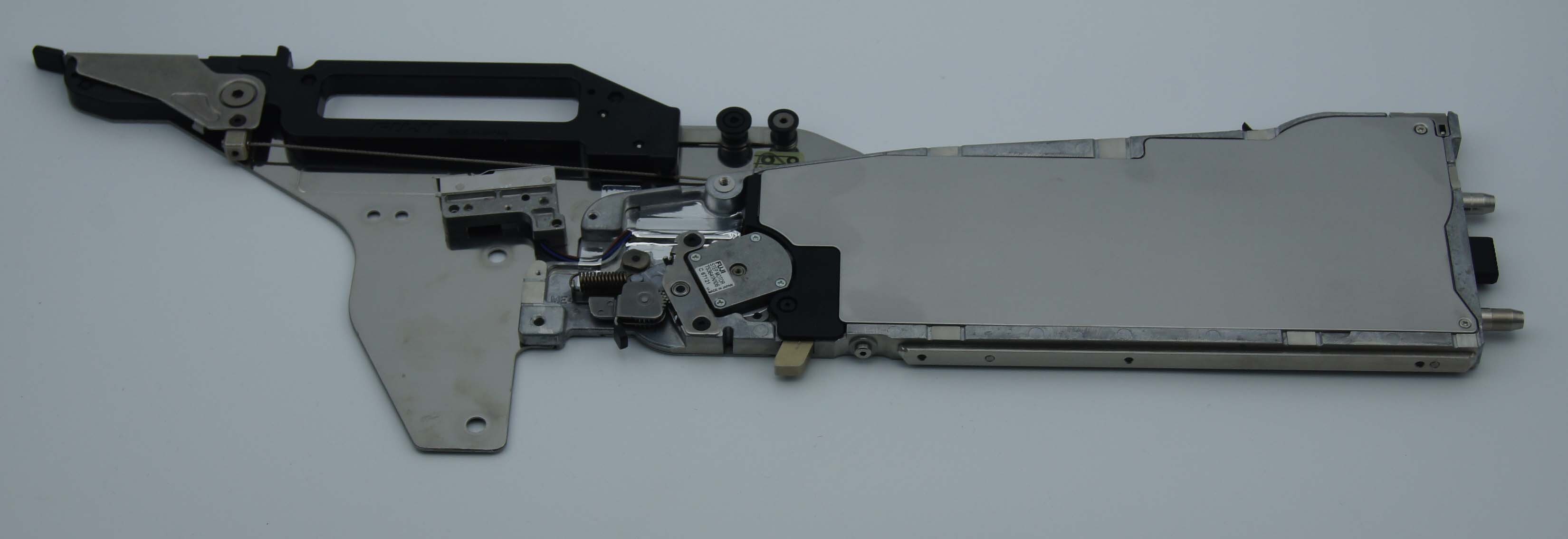

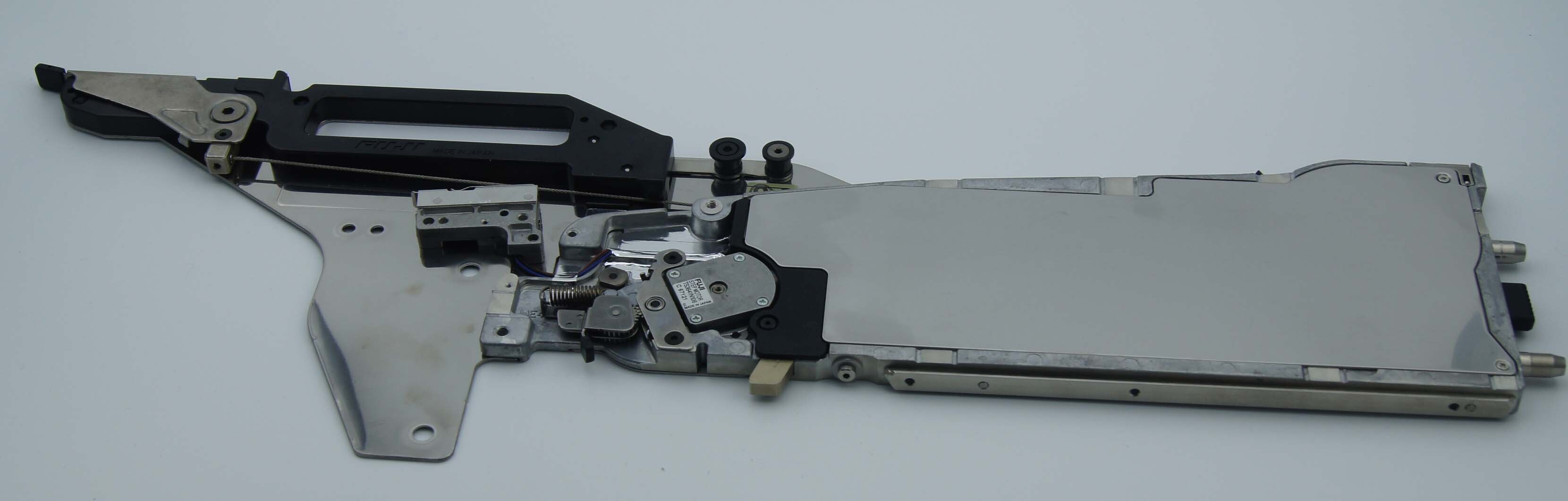

Used FUJI NXT II #9064619 for sale

URL successfully copied!

Tap to zoom

FUJI NXT II is a highly versatile PC Board Assembly and Manufacturing equipment that provides outstanding production output. FUJI NXTII utilizes a three pick-and-place head multi-gantry structure to handle PCBs with precision and speed. This particular system is also equipped with a high-accuracy placement head, allowing it to accurately place components down to 0201 size packages. NXT II also features an intuitive graphical user interface, allowing the operator to quickly and easily understand the current production status and incoming board designs. NXTII utilizes a highly advanced machine vision unit to enable fast and precise component positioning and placement. The machine vision machine works in conjunction with the placement head to capture images of the board during programming and execution, providing real-time feedback to the operator via the graphical user interface. The machine vision tool is also staged with an onboard alignment and inspection asset that ensures every component is correctly placed and inspected accurately before proceeding with the next step. FUJI NXT II also offers an advanced assembly process control model, allowing it to automatically adjust placement speeds based on a variety of input factors. This equipment can operate in either PC Board Assembly mode or in Manufacturing mode, allowing operators to select the optimal board production process for the job. Additionally, FUJI NXTII offers an enhanced component supply mechanism, allowing operators to quickly and easily replenish supply components as needed. In terms of accuracy, NXT II is capable of producing boards with extremely high accuracy. The system is capable of placing components with an accuracy exceeding 0.08mm, making it an ideal choice for highly accurate board manufacturing and assembly. Additionally, NXTII utilizes an advanced vision-aided alignment unit to reduce mis-pick errors and improve board placement accuracy. In addition to its production and assembly capabilities, FUJI NXT II also offers comprehensive test capabilities, allowing it to fully inspect component placement and detect any defects that are present. The machine utilizes a component test/repair head to quickly detect any blown or missing components, as well as an AOI (Automated Optical Inspection) head for high-speed inspection of board accuracy during the assembly process. All in all, FUJI NXTII is an ideal choice for PC board assembly and manufacturing, offering a wide range of production and assembly features for maximizing output and accuracy. With its highly intuitive graphical user interface, advanced assembly process control tool, component supply mechanism, and comprehensive test capabilities, NXT II is a top-of-the-line PC Board Assembly and Manufacturing asset.

There are no reviews yet