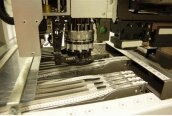

Used FUJI NXT M3 #9178076 for sale

URL successfully copied!

Tap to zoom

ID: 9178076

Vintage: 2006

Modular placing machines

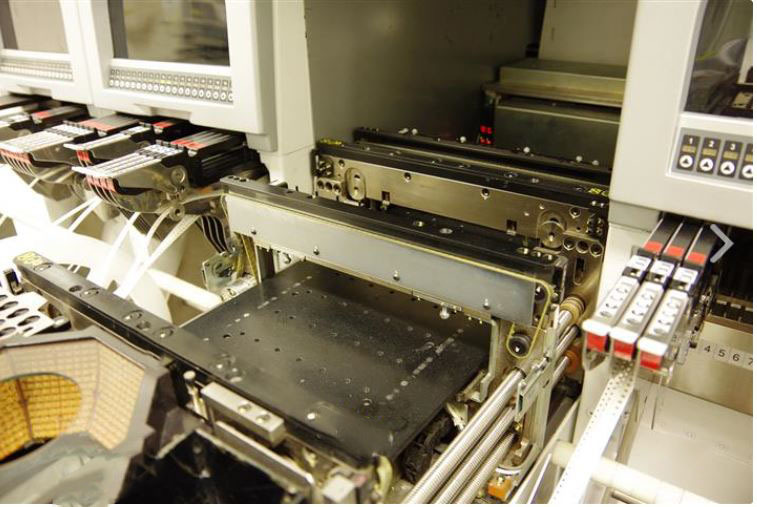

4M Independent base with CPU

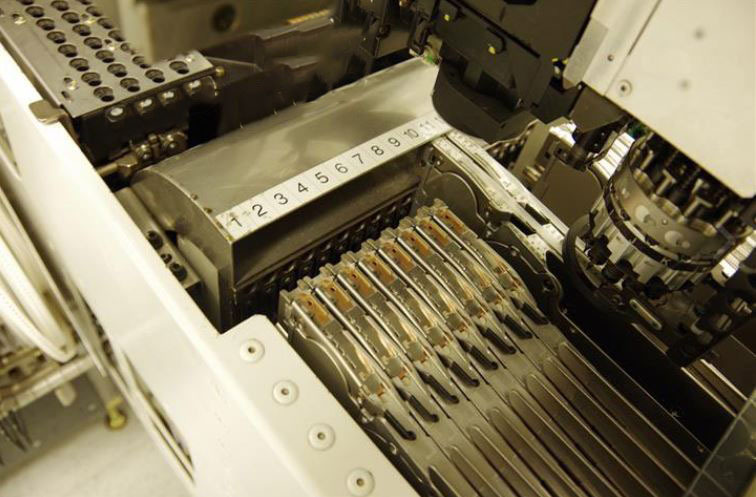

Double conveyor:

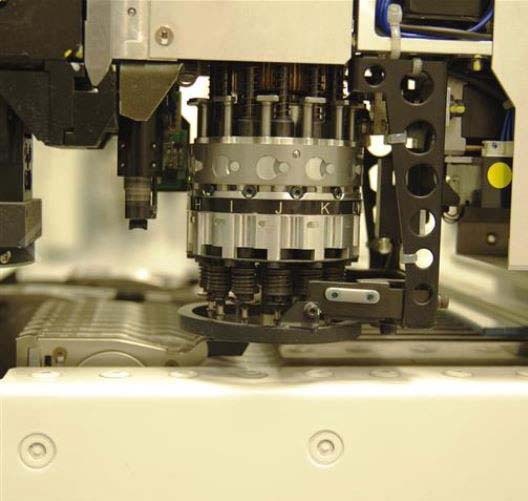

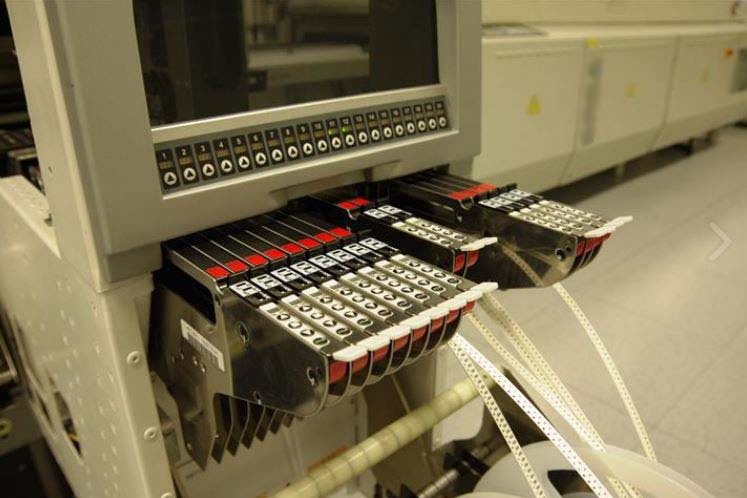

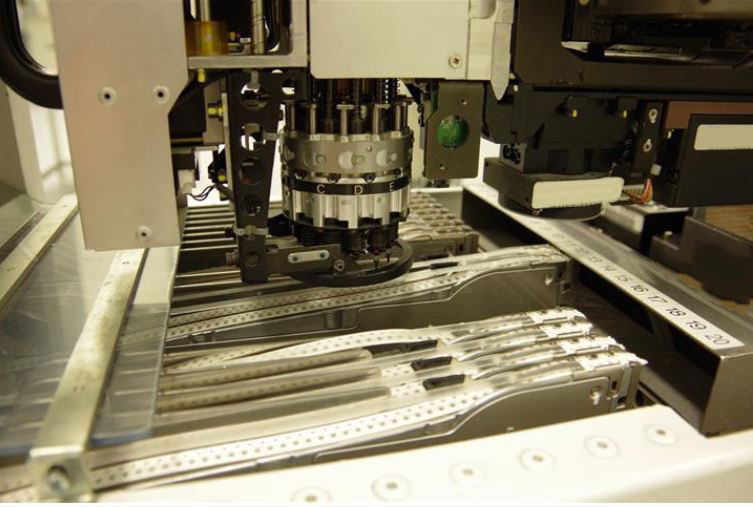

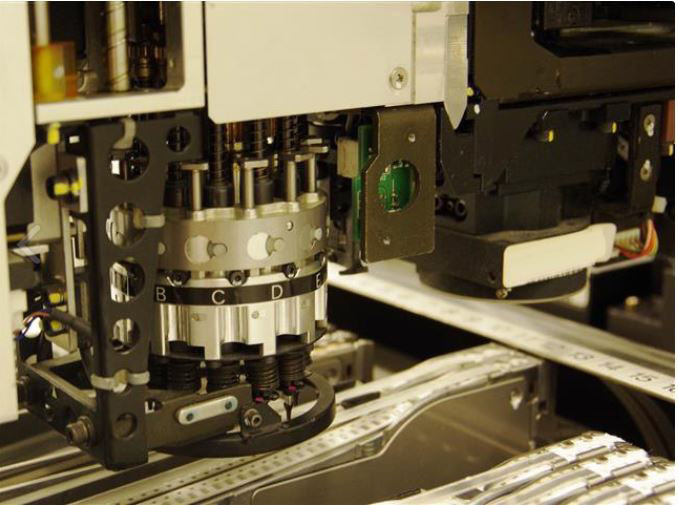

(3) H12 Heads

(1) H08 Head

With nozzle changer

Automatic back up pin option

Include: Vacuum pack

2006 vintage.

FUJI NXT M3 is a highly advanced all-in-one pc board assembly and manufacturing equipment designed to meet the needs of modern production environments. The system includes an embedded computer, an embedded software unit, specially developed hardware and component sorting capabilities. With its highly reliable and flexible platform, NXT M3 can be used to effectively manage and group high-volume production batches with a single stroke. The machine uses an optimized workflow based on its advanced component placement functions and an advanced real-time computerized vision inspection tool that ensures all components are properly identified and correctly located. The asset also features an extensive parts library that can store up to thousands of components for easy selection and sequential placement. With its robust material handling features, FUJI NXT M3 can be configured to suit the size and speed of production processes and deal with the most common component types. Basic features of NXT M3 include: a single assembly head capable of making both chip and nozzle type placements; customized component placement programs that can be easily changed remotely or locally; an integrated vision model for accurate component identification and placement; a highly accurate chip-sorting process; and a high-capacity and high-speed data storage equipment for component information. The system also uses advanced real time detection systems that allow for the detection of the vibration and voltage fluctuations that can occur during assembly to ensure accuracy and prevent damage. The unit relies heavily on its advanced computerized vision inspection capabilities, which allow it to accurately identify parts even if they are damaged or unable to be read by ordinary systems. This machine can also be used to prevent wrong components from being placed in the wrong locations. For extra accuracy, it can be used in conjunction with offline programming tools to ensure further accuracy in the placement of parts and components. In addition, FUJI NXT M3 offers unparalleled flexibility in its work processes with the ability to manage multiple production processes including board testing, component placement, component and board inspection, labeling, polishing, and soldering. All of these processes are easily manageable via the comprehensive embedded software tool. Furthermore, the asset can be implemented on virtually any production line, making it suitable for a wide range of industries and applications. Overall, NXT M3 is an extremely powerful and efficient tool for pc board assembly and manufacturing. Its advanced placement and inspection capabilities combined with its extensive parts library offer unparalleled flexibility and accuracy for all pc assembly processes. The model relies heavily on its computerized vision equipment and can help to dramatically reduce production waste and cost.

There are no reviews yet