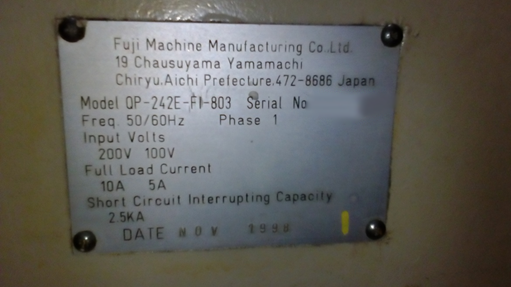

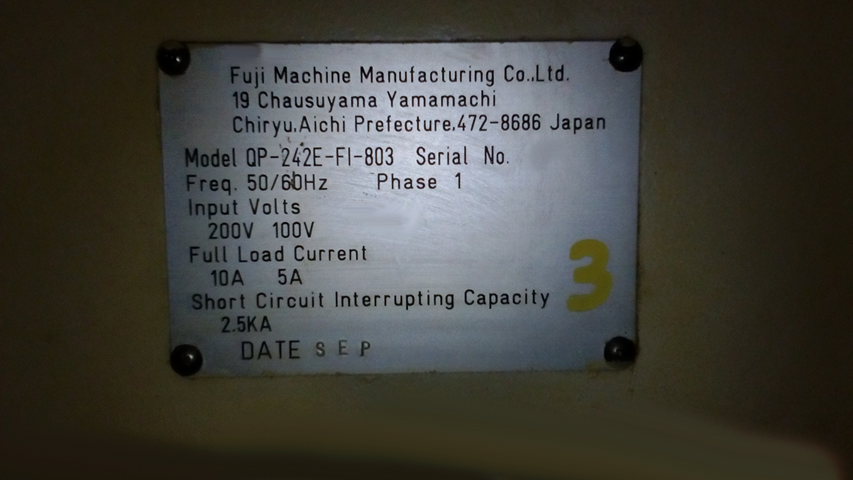

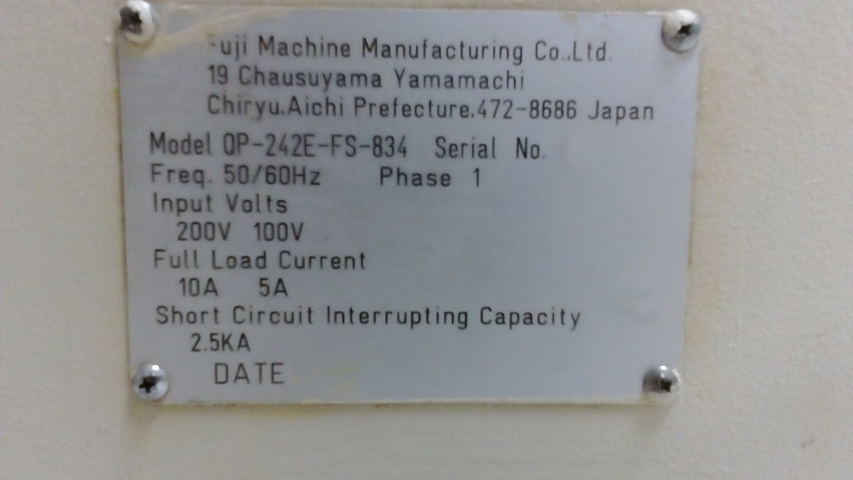

Used FUJI QP 242E #9127131 for sale

URL successfully copied!

Tap to zoom

FUJI QP 242E is a highly advanced PC Board Assembly and Manufacturing Equipment. This system is designed to increase overall throughput and capabilities while at the same time significantly reducing operating costs. In this unit, the component placement, board inspection, integrated programming, and testing operations are all fully automated. The placement module of FUJI QP242E is equipped with high-speed, precision machine vision and robotic technologies. It can handle a wide variety of components including surface mount, through-hole and small-form packages. It's equally suitable for both hard- and soft-mounted components. It requires minimal manual intervention, and all operations are monitored, recorded and reported with an easy-to-understand GUI interface. The high placement accuracy makes it suitable for the most complex applications. QP 242 E also utilizes advanced board inspection technology. A custom-designed camera machine can inspect for defects and accuracy on both sides of the board, and alert operators in real-time if any issues are observed. It also provides detailed feedback about component and placement accuracy, allowing operators to correct any inconsistencies prior to final assembly. The integrated programming feature of QP 242E provides an easy-to-use tool for designing and programming boards that will be used in production. It is capable of handling complex designs with detailed programming information for the most demanding applications. The tool's test capabilities also ensure the entire board is working as expected and ready for shipment. The asset performs a series of tests prior to shipment for both quality assurance and to ensure the board is functional. It checks for proper functionality of the board and can help troubleshoot any issues that may arise. Overall, FUJI QP 242 E is an extremely efficient and effective PC Board Assembly and Manufacturing Model. It has numerous features that make it suitable for even the most complex applications. The automation of the component placement, board inspection, programming, and testing capabilities makes this equipment a reliable and cost-effective solution for any PC Board Assembly and Manufacturing requirements.

There are no reviews yet