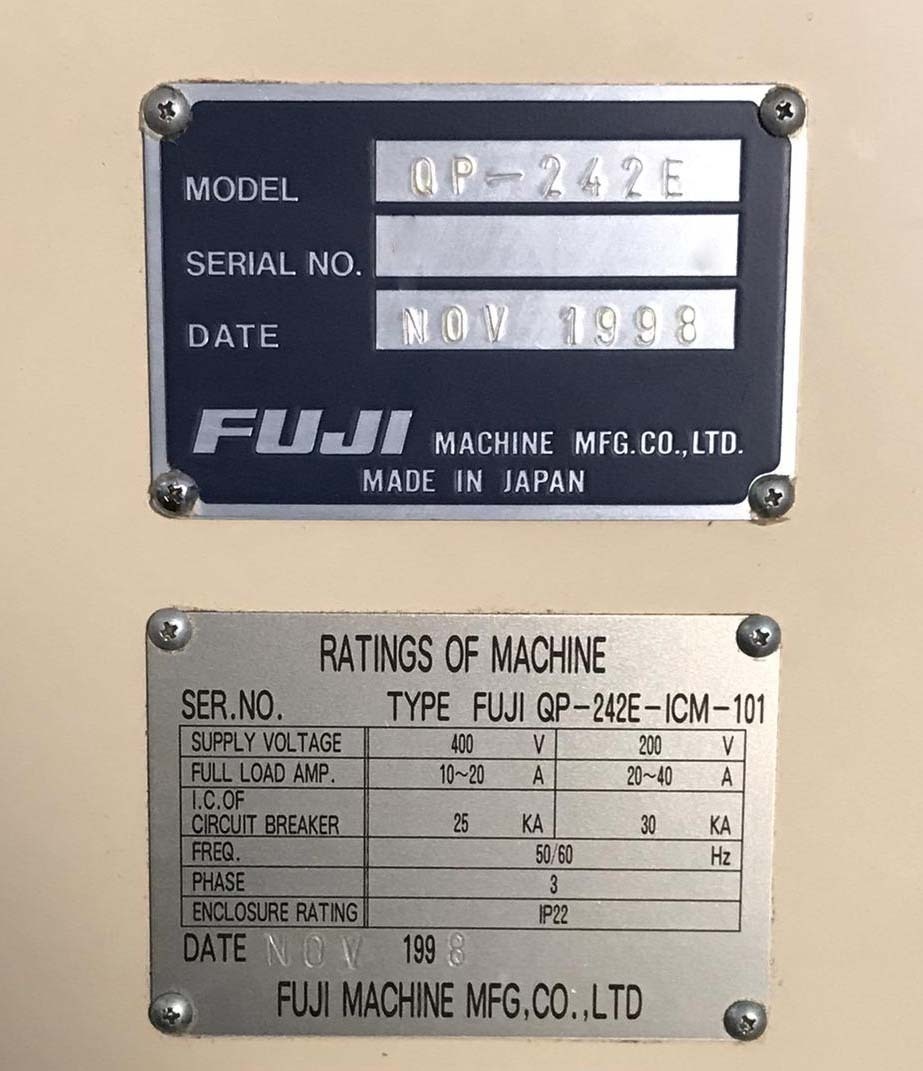

Used FUJI QP 242E #9300930 for sale

URL successfully copied!

Tap to zoom

ID: 9300930

Vintage: 1998

Pick and place machine

Feeders:

Qty / Size

(10) / 8 mm

(11) / 12 mm

(18) / 16 mm

(13) / 24 mm

(5) / 44 mm

(6) / 32 mm

1998 vintage.

FUJI QP 242E is a PC board assembly and manufacturing equipment. It utilizes a high speed, high accuracy linear motor driven quick pick and placement machine that can pick and place components up to 0201 in size and is capable of handling both 8mm and 12mm feeders. The machine's ultrafast pick and place speed allows for processing in a fraction of the time that traditional machines require. Furthermore, FUJI QP242E is equipped with two camera heads and an on-board vision system that provides integrated inspection capabilities. This unit is able to detect damaged or misapplied components and take the necessary corrective action while the machine continues to operate. The innovative vision machine also features an external camera source that can be used to inspect the orientation and polarity of components prior to and immediately after placement. QP 242 E is equipped with two nozzle changers that allows a maximum number of 24 heads with 12 nozzles each. This reduces significantly maintenance time, as the nozzles can be changed in a single cycle, while the machine continues its operation and availability is maintained. The machine also features auto-clean function that cleans all nozzles after a certain component is placed, so that no additional maintenance from the user is required. FUJI QP 242 E excels in its accuracy and offers a total combination of accuracy and speed. It has the ability to place up to 72,000 components per hour with an average accuracy of ± 0.02mm, providing a highly reliable and efficient assembling process. The component verification is carried out in real time, allowing any errors to be detected and corrected immediately, thus guaranteeing a high quality board assembly. In addition, QP 242E features an advanced software that allows for easy, efficient and accurate programming and setup of the machine. It also provides visualization of the product on the production line, which allows the user to view the assembly process in real time and detect any problems or errors that arise. The user friendly graphical interface also allows for easy data monitoring and analysis. QP242E offers an automated board assembly solution for a wide range of applications as it is suitable for both large and small volumes of boards. The advanced software and integrated vision tool ensures accuracy and quality in each board assembly, making it the perfect choice for any type of PCB manufacturing.

There are no reviews yet