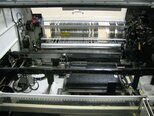

Used FUJI XP 143E #9312043 for sale

URL successfully copied!

Tap to zoom

FUJI XP 143E is a fully automated PC board assembly and manufacturing equipment designed to bring accuracy and precision to the production of printed circuit boards (PCBs). It has an impressive array of features to maximize efficiency in the PCB assembly process. The system utilizes four FUJI placement heads to accurately place components onto the PCB with a maximum placement speed of 48,000 CPH (components per hour). It also features an intuitive and reliable vision unit to inspect component placements, thereby eliminating human error and ensuring high-quality results. FUJI XP143E is designed to be completely self-contained for efficient and productive PCB assembly operations. It comes with a feeder machine featuring 60 pocket-feeder cassettes, feeders for bulk storage of items, and a 3D mounting motor to precisely position components. In addition, the tool is equipped with an automated fill-in mounter that enables it to perform both fill-in and mid- board rotation operations. XP 143 E also features an inline tinning asset that enables it to perform PCB tinning operations directly onto the PCB, without the need of an additional tinning machine being employed. It is capable of performing both selective and whole-board tinning. Furthermore, the model is equipped with a pulse oven to evenly apply solder paste to the pads of the PCBs and perform accurate reflow soldering. The intelligent temperature control of the oven ensures that components are not damaged due to excessive heat. XP 143E also comes with an automatic inspection equipment to ensure that all components and connections have been properly placed and soldered. It is equipped with an Array-Hotcal heater to optimize the soldering connection strength and a Ground Wire Placement system to ensure stable electrical connections between the ground wire and various components. As a result, FUJI XP 143 E provides a reliable and efficient solution to meet the needs of today's PCB manufacturers. It is built to deliver precision and accuracy for a wide range of PCB assembly needs, and can be easily maintained and serviced for stable PCB production over long-term use.

There are no reviews yet