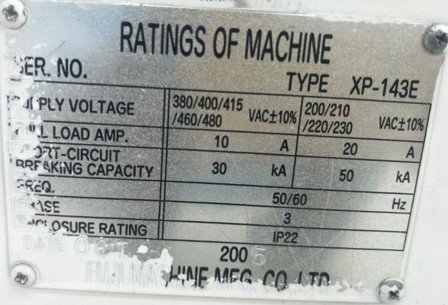

Used FUJI XP 143E #9383642 for sale

URL successfully copied!

Tap to zoom

FUJI XP 143E is a state-of-the-art PC Board Assembly and Manufacturing Equipment, a fully automated robotic system designed specifically for the manufacturing and assembly of printed circuit boards. It is designed to increase production efficiency, reduce labor costs, and prevent manual errors in the production process. FUJI XP143E unit is comprised of several components that work together to produce the desired end product. The first component is the PC Board transport unit which uses an indexer and motorized conveyor belt to transport the PC board components to the work stations in the manufacturing process. The integrated Unloader-Indexer is the second component which loads and unloads PC components from the conveyor belt and directly loads the components onto the assembly line. The third component is the advanced Multi-Area PC Board assembly station, which uses a combination of sensors and conveyors to assemble and interconnect the components on a single PC board. The fourth component is the Finish Printing Unit, which uses an UV printer to etch the printed circuit boards. The integrated Intelligent PC Board assembly machine allows thesystem to perform high precision, cost effective and automated SMT assembly in a significantly short period of time. It is capable of stamping samples at adjustable speeds, ensuring each product has the highest quality and reliability. Furthermore, a wide variety of solder paste and processing materials are available, allowing for greater flexibility and potential expansionability. The automated smart-handling compoulpter machine ensures the highest accuracy and safety when dealing with PC boards and components. XP 143 E PC Board assembly and manufacturing tool also includes several advanced diagnostics, trouble-shooting, and calibration features. These features allow more precise and accurate asset control, which in turn helps to improve the overall quality of assemblies produced on the model. Additionally, the equipment is equipped with a powerful diagnostic tool that provides detailed information about the machine's performance and can be used to detect potential problems in the assembly or manufacturing process. FUJI XP 143 E can also be programmed to carry out complex production cycles depending on the particular production requirements. For example, the system can be programmed to individually assemble the PC board components, apply solder connections to the components, and then connect the components to each other using a specialized soldering unit. This allows for a rapid and precise production process that yields exceptional quality assemblies. Overall, XP143E PC Board Assembly and Manufacturing machine is an extremely versatile and easy to use tool that is designed to help improve efficiency and reduce errors and waste in the production process. With its advanced features and diagnostic capabilities, XP 143E is a valuable asset to any electronics manufacturer.

There are no reviews yet