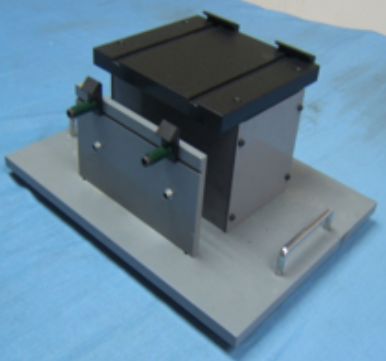

Used FUJI XP 243 #9088355 for sale

URL successfully copied!

Tap to zoom

FUJI XP 243 is an advanced PC Board Assembly and Manufacturing equipment which can help streamline and optimize production processes of various manufacturing applications. It features a full robotic assembly platform including FUJI IP3 and IP4 CNC motion controllers. This system has a hosting capacity of up to 10,000 points allowing for numerous assembly operations to be performed under one roof. Its modular design provides for maximum for cost efficiency and stability in demanding production environments. The unit includes a jigless auto feeder for the feeder housing of up to 200 mm between the feeding tapes. This ensures smooth and efficient operations even with large boards since the operator needs to only load the tape once and then the feeder will smoothly make its way along the entire width. The feeder also allows adjustment of PCB width and thicknesses as desired in order to ensure that there is compatibility with the setup process. XP 243 is equipped with a high speed camera machine that can be used to rapidly recognize components and its placement on the board. This enables faster transition of components from one production step to the other. The vision tool also boasts an ultra-high definition resolution which makes certain that all parts are detected and placed correctly in their intended locations. The asset is also fitted with a load and unload unit that allows for the placing of the board-in-making on the production table. The model also includes a continuous vacuum nozzle suction equipment which helps to prevent misplacement of components. Mounted on this contraption is a component identification unit which may be used to detect variations in component size as desired by the manufacturer. FUJI XP 243 features an advanced vision-based top down mount system. This unit moves at a speed of 290,000 CPH and can achieve a component placement accuracy of +/- 0.035mm. The machine includes geometrical programming for advanced vision and helps to minimize errors caused due to component offset deviation. Additionally, this PC Board Assembly and Manufacturing tool is capable of advanced mis-component discrimination to detect erroneous component placement and minimize component assembly wastage. It also incorporates a sub-PCB sampling station which helps to further reduce assembly time significantly. XP 243 asset is designed to ensure accuracy, repeatability, and minimum downtime. Its advanced features help streamline assembly and production processes, reduce waste and costs, and increase productivity and efficiency. This model is indeed a valuable addition to any production environment and will certainly help boost the company's bottom line.

There are no reviews yet