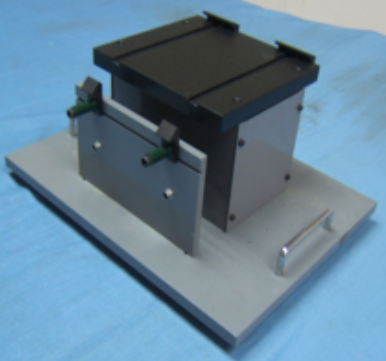

Used FUJI XP 243E #146905 for sale

URL successfully copied!

Tap to zoom

FUJI XP 243E is a full-featured, totally integrated, RFID-controlled, pc board assembly and manufacturing equipment designed to meet the needs of a wide range of high-volume production environments. The system is designed to allow users to quickly and easily create cost-effective pc board assemblies with every aspect of the production process automatically tracked and managed. The unit is provided as a complete package, containing all the components necessary for operation. This includes a conveyor, component feeders and loader, placement heads, sensors, laser, vision systems, and various software components. The conveyor machine is designed to provide a smooth, reliable transport of pc boards through the tool, ensuring accuracy during assembly. The component feeders and loader are provided to accurately and reliably feed components from the appropriate bins onto the pc boards. The placement heads are highly accurate and permit up to 25,000 placements per hour. This allows for high-volume production without sacrificing quality. The integrated vision asset is also used for component identification and placement alignment and works in conjunction with the laser model to measure components prior to placing them on the board. The integrated RFID equipment is used to track components, monitor the production process, and record production results. This system not only helps reduce operator errors but also allows production to run with minimal manual interventions and oversight. The software components are designed to control and monitor the entire production process. This ensures maximum efficiency and accuracy while providing the necessary data to make informed decisions. The unit is designed to be highly flexible and easily customizable, allowing users to quickly adapt to changing product requirements. Overall, FUJI XP243E is an excellent pc board assembly and manufacturing machine that provides a high level of automation and reliability. The integrated RFID tool, vision systems, and software provide an efficient, cost-effective solution for high-volume production environments.

There are no reviews yet