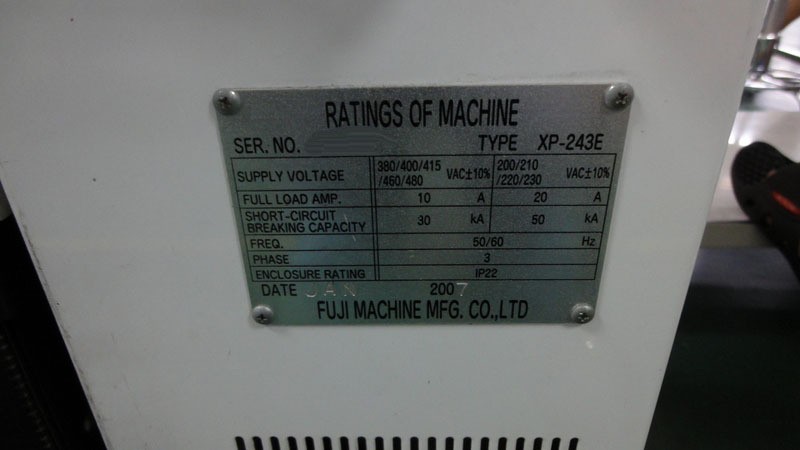

Used FUJI XP 243E #199832 for sale

URL successfully copied!

Tap to zoom

FUJI XP 243E is a PC Board Assembly and Manufacturing equipment. It is designed for efficient prototyping and production of high-quality and reliable electronic board assemblies. The system provides flexibility and scalability of components, allowing customers to customize their assembly workflow. It includes a comprehensive set of tools to aid in component placement, programmable fieldbus operations, reflow soldering, vision inspection, solder paste printing and dispensing. All these features increase production speed and quality. FUJI XP243E is designed to meet the needs of fast tract prototyping and production. It features a short-legged programmable flexible CPN fieldbus architecture, enabling real-time motion control, component placement, and programmability. Moreover, it is equipped with a high-resolution 10.4" LCD display. Combined with an intuitive graphical user interface and high-speed image processing, XP-243 E increases programming time and accuracy. FUJI XP-243 E has different modules that offer the highest flexibility for the customer. The Automated Optic Centric (AOC) placement head is used to position and place components accurately. AOC information is then transferred to a reflow soldering module. The soldering module is equipped with FUJI floating wave micro-adjustable reflow soldering technology, enabling high precision soldering across multiple zones. For vision inspection, FUJI XP 243 E is equipped with a solder paste module built into the soldering unit. Operators can view and edit programs with a wide range of visual aids such as LED, the Last Good Known View (LGKV), test print preview and color mismatch analysis. XP 243E also features multiple integrated dispensing functions. The dispensing head supports multiple adhesive and flux options and utilizes its dispensing speed adjustability to optimize material usage while delivering precise accuracy. XP243E's process diagnostics provide real-time performance data for better control. Data such as total cycle time, number of placements /sec, and total number of placements are securely archived and accessible from multiple stations. Furthermore, XP 243 E complies with regulatory environmental requirements and comes with a self-diagnose machine for maintenance. The tool also meets RoHS compliance standards. FUJI XP 243E PC Board Assembly and Manufacturing asset is designed for quick prototyping and production of reliable and high quality products. It offers enhanced speed and accuracy with its comprehensive suite of tools and modules, and ensures that production meets all environment regulations and standards.

There are no reviews yet