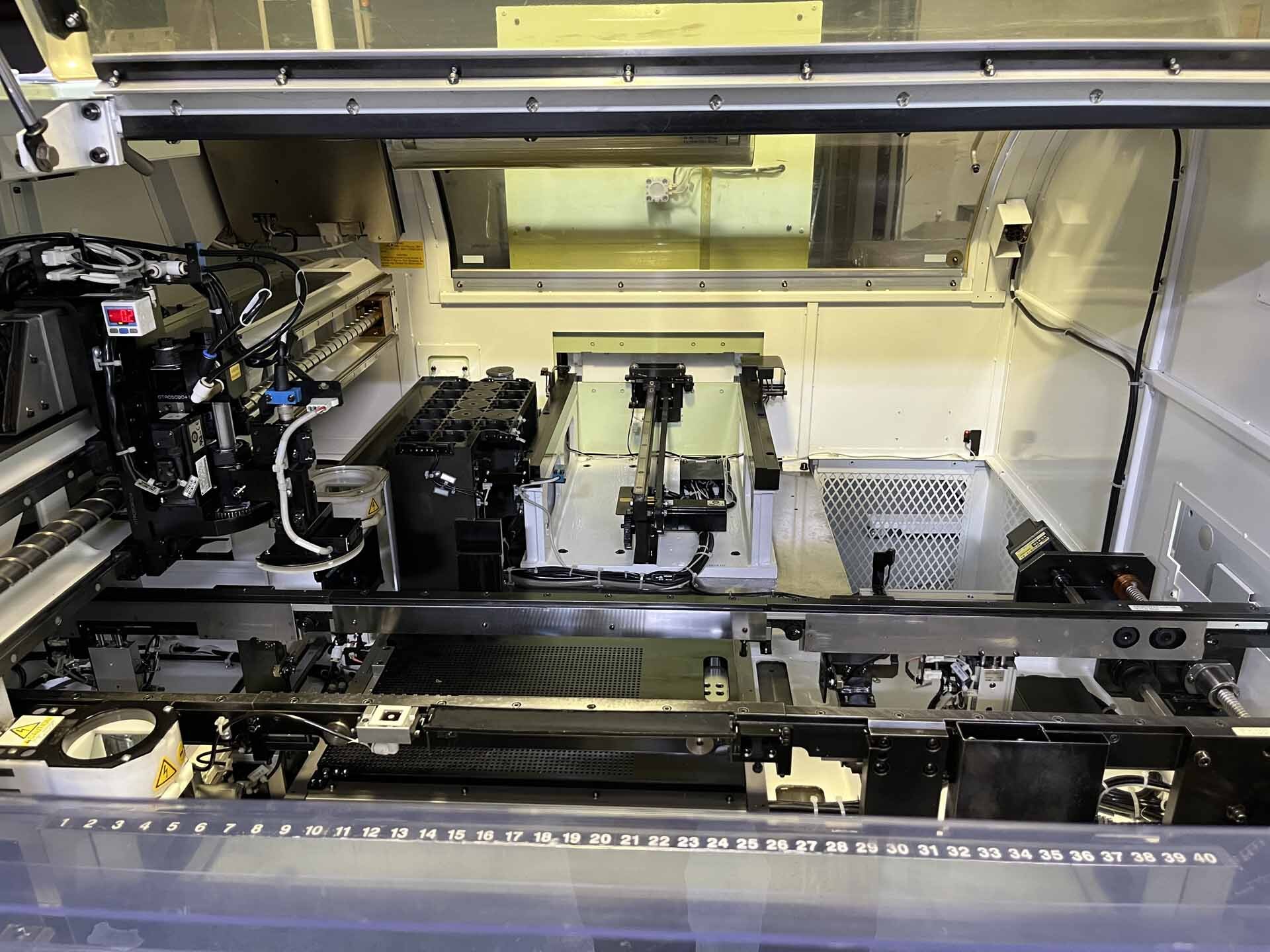

Used FUJI XP 243E #293659408 for sale

URL successfully copied!

Tap to zoom

ID: 293659408

Vintage: 2006

Chip shooter

Mobile Feeder Platform (MFU)

MTU Tray

2006 vintage.

FUJI XP 243E PC Board Assembly and Manufacturing Equipment is an automated production equipment system designed to deliver precision and cost-effectively manufactured Printed Circuit Boards (PCBs). This unit sets itself apart with its ability to deliver high-quality, volume-manufactured products consistently and reliably. FUJI XP243E PC Board Assembly and Manufacturing Machine is highly advanced, featuring a wealth of features. It is equipped with 64-sites multi-stage assembly and cutting capability that ensures precise and accurate processing of parts. Each of its multi-stage assembly functions can be operated individually, allowing for maximum flexibility to accommodate diverse production needs. XP-243 E PC Board Assembly and Manufacturing Tool is constructed with a high-performance, ultra-durable aluminum chassis. This provides the asset with stable operation, remarkable durability, and a consistent finish for each manufactured product. The model is designed with a modular structure that allows for easy maintenance and continuous operation. The equipment also features a highly powerful, yet user-friendly software that ensures easy operation and efficient workflows. The intuitive software interface highlights real-time production information, including production progress and assembly time, alerting operators of any issues that may arise. For complex assemblies, XP 243 E PC Board Assembly and Manufacturing System provides a wide range of features, ranging from library-based tendering to pre-programmed customized functions. The library-based tendering function allows operators to easily access components from any library, while the customized functions provide operators with an unprecedented level of control for intricate components. The unit also includes an array of technological advancements, such as "SpeedLine" technology and "STL-Ops" technology. The "SpeedLine" technology helps maintain a controlled, linear flow of components to be placed and the "STL-Ops" technology offers a fully automated picking and subsequent placement of components within a defined accuracy and speed. To further enhance the efficiency and overall performance of production process, FUJI XP-243 E PC Board Assembly and Manufacturing Machine has multiple service options available, including tool/tape feeder, rotary mounter-motor relay, bar base-tender loader, and soldering robot systems. The bar base-tender loader is particularly useful, as it is able to check and monitor bar codes of components before loading components into the device. In addition, XP 243E PC Board Assembly and Manufacturing Tool is compliant with industry-leading standards and is capable of operating in a wide range of temperatures. This ensures high reliability and consistent performance even in extraordinary conditions. XP243E PC Board Assembly and Manufacturing Asset is an integrated multifunctional equipment model designed to increase throughput and competitiveness in the production of Printed Circuit Boards (PCBs). Its intuitive user interface, advanced features, and powerful software make it an ideal choice for ensuring reliable, cost-effective production of high-quality PCBs on a consistent basis.

There are no reviews yet