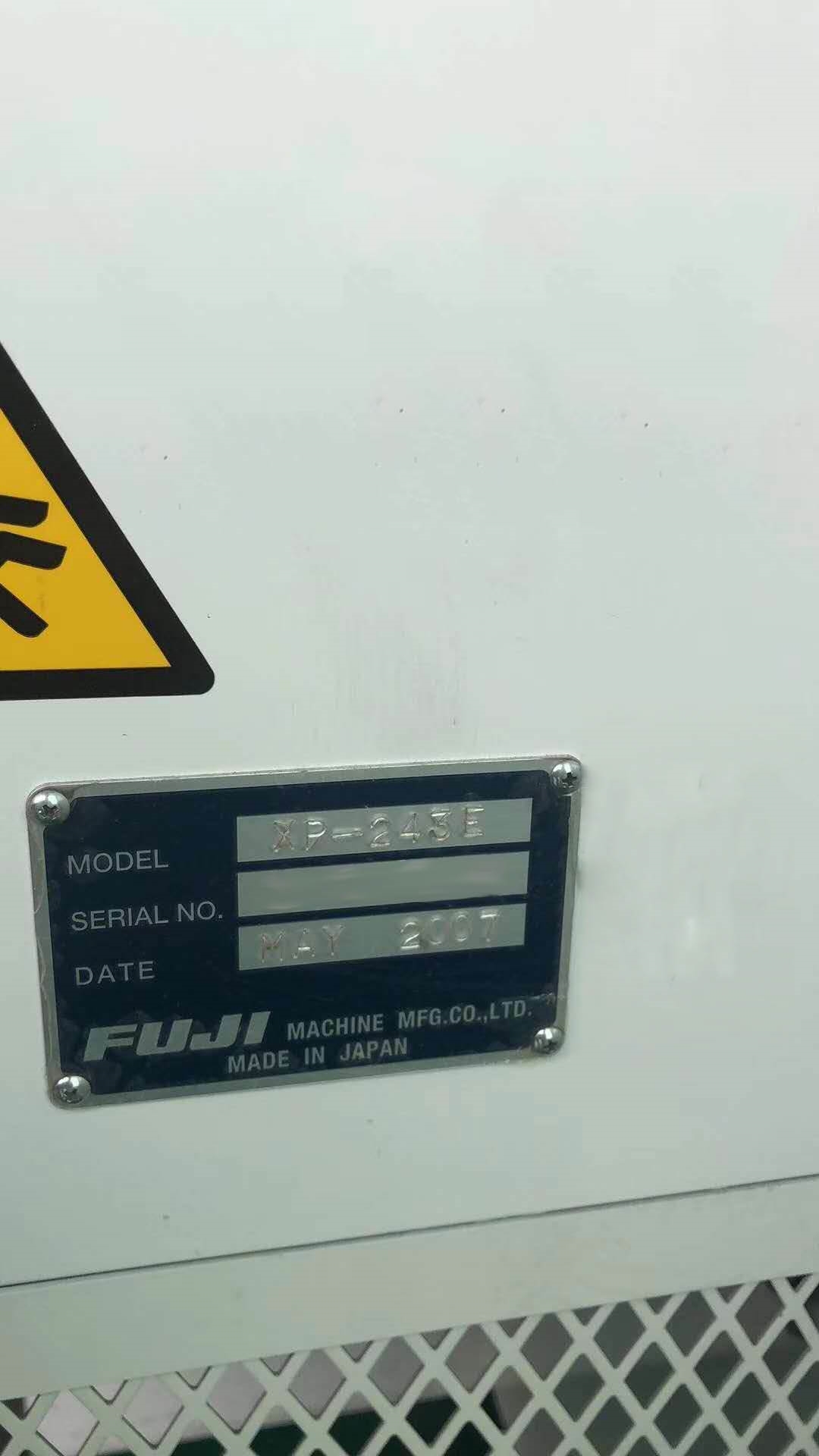

Used FUJI XP 243E #9273187 for sale

URL successfully copied!

Tap to zoom

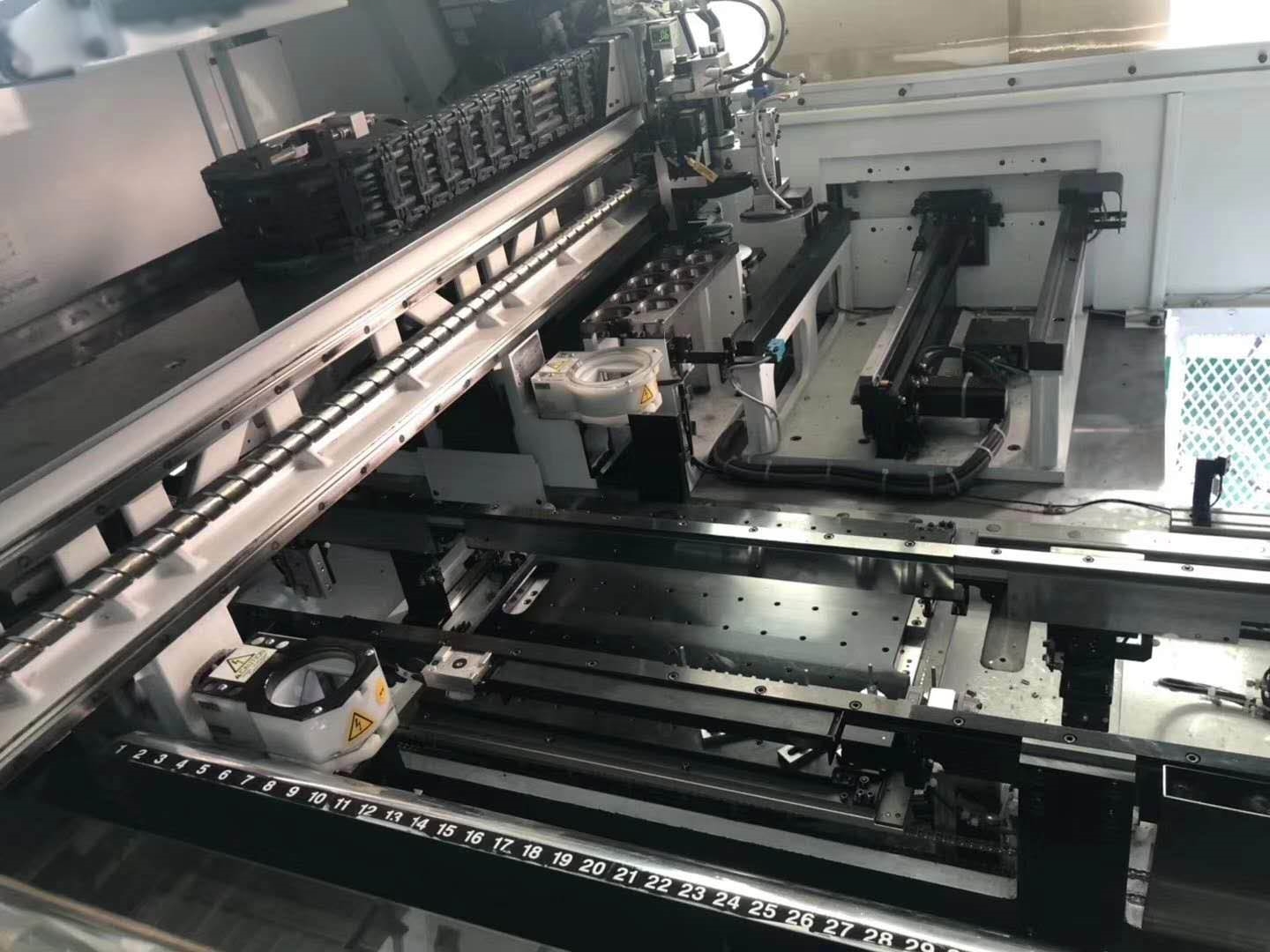

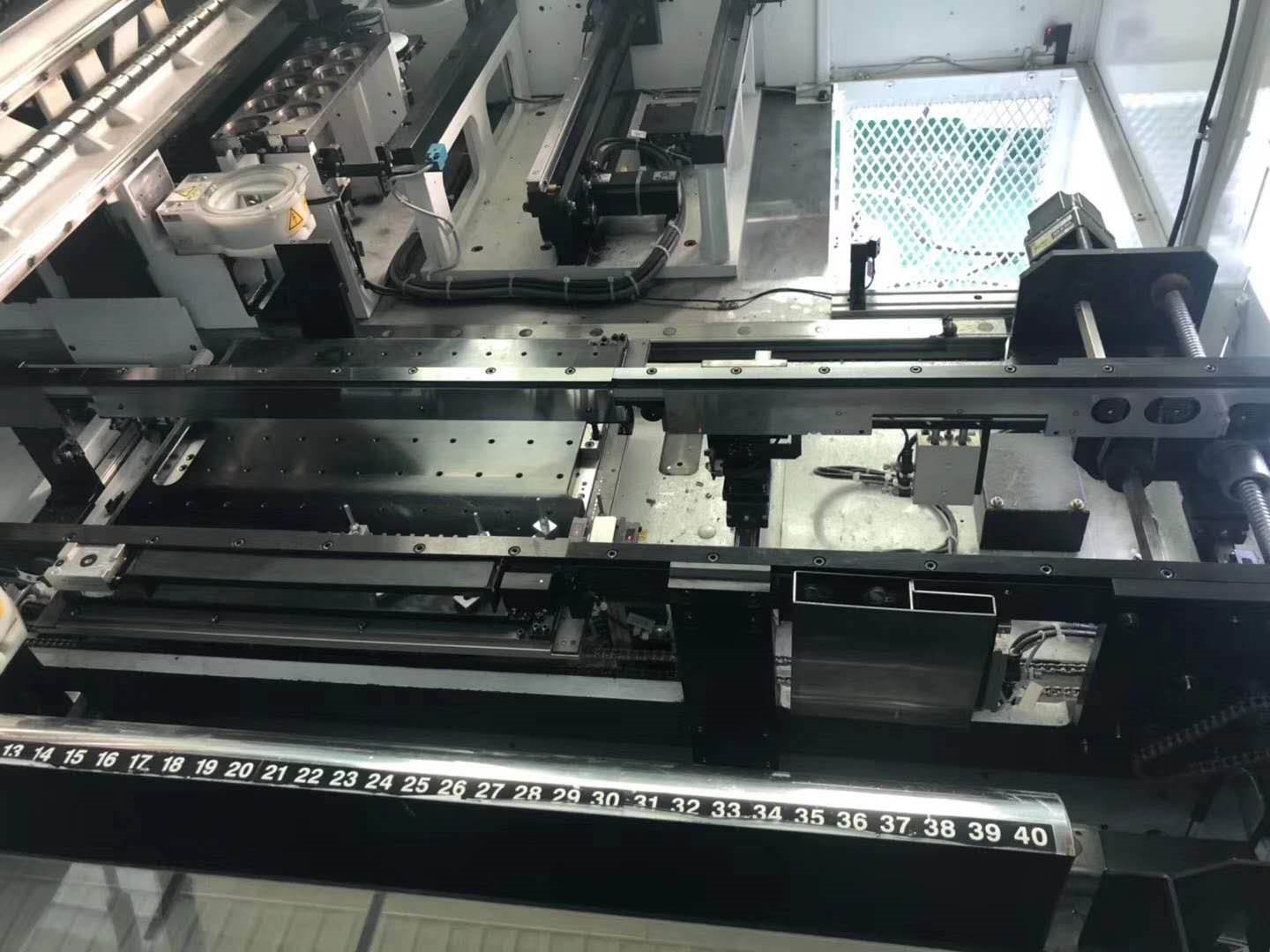

FUJI XP 243E is a pc board assembly and manufacturing equipment designed for high-speed production of electronics. The system is an image-recognition unit capable of placing components correctly onto pc boards. The machine utilizes vision sensors that can be used to read and recognize component identification, orientation, and placement. The tool can be adapted to identify various types of electronic components, such as capacitors, resistors, quartz devices, and power devices. Additionally, the asset can accommodate a variety of pc board sizes, including through-hole and surface mount technology. FUJI XP243E is configured with two independent head units, each capable of independent motion. This allows for fast component placement and pick-and-place operations. A pitch interval automatic feeder is used to feed components to the head units. The feeder is compatible with tapes, strips, or reels and can handle up to 16 components at a time. A multi-chip detection model is used to reduce errors in component identification and placement. The equipment also utilizes a flexible and powerful software that makes it easy to program and operate. The programming interface makes it possible to program the system to place components within different sizes and placements. It also supports image processing and machine vision applications, which can be applied to verification, component detection, and defect inspection. Overall, XP-243 E offers high speed and capacity for pc board assembly and manufacturing. It is capable of handling components of different sizes and types and can accommodate various placement designs. Its image processing capabilities can be utilized for defect inspection and component placement verification. And its powerful software makes it easy to program and operate the unit.

There are no reviews yet