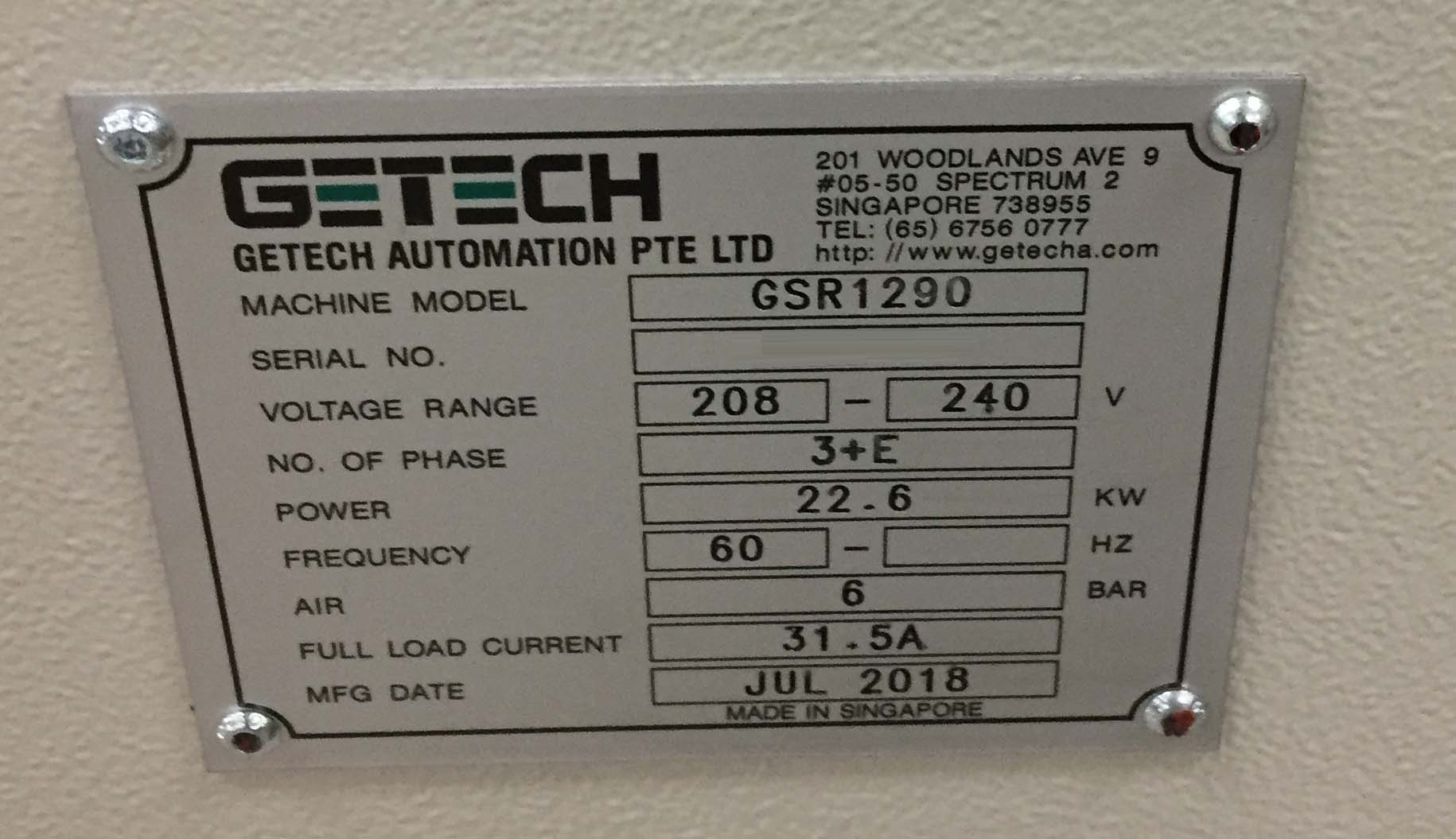

Used GETECH GSR 1290 #9257999 for sale

URL successfully copied!

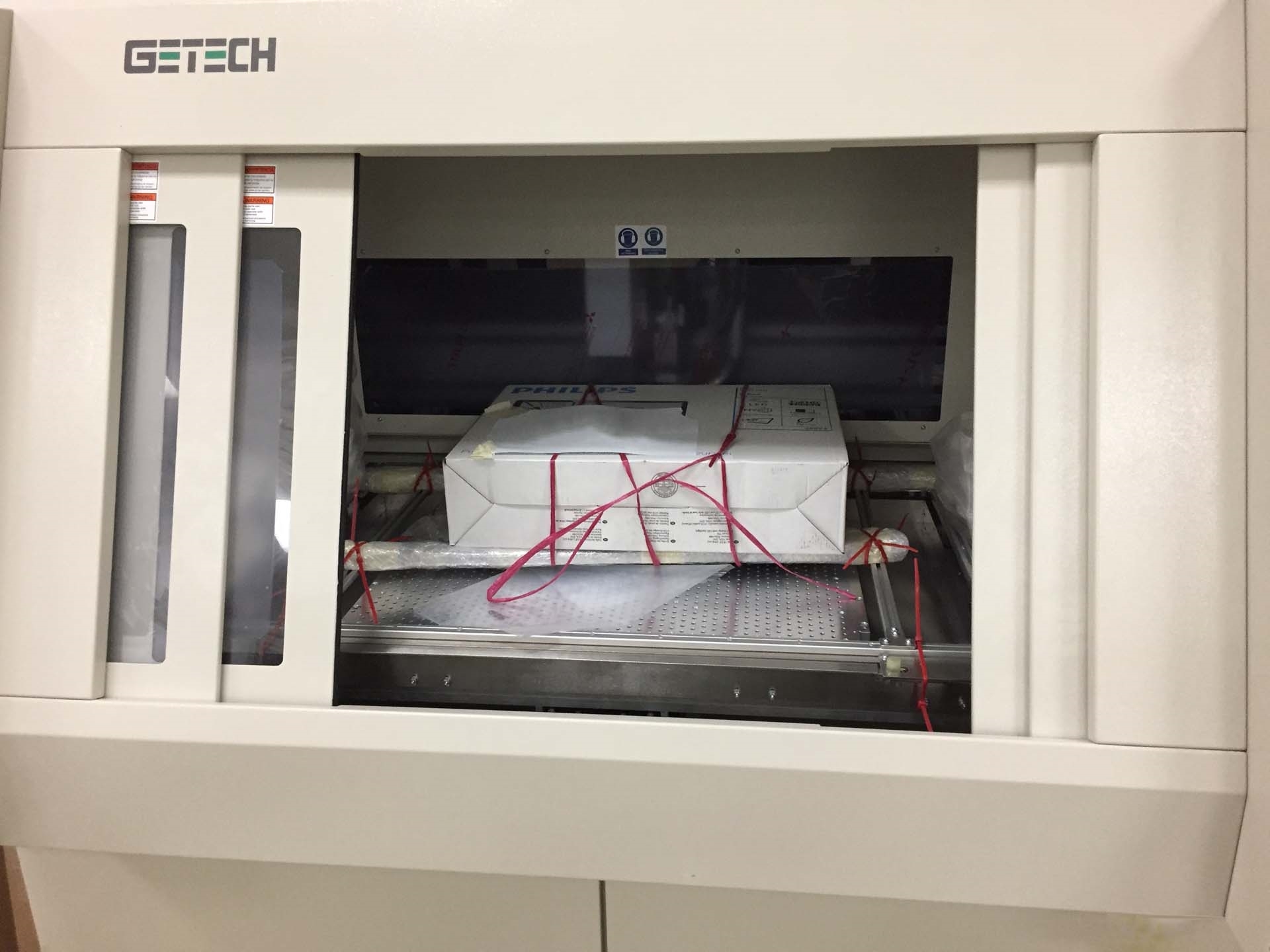

Tap to zoom

ID: 9257999

Vintage: 2018

Semi automatic router

4041 Spindle

(2) Vacuum blowers / Dust filter tanks system

Work station: 910 mm x 610 mm

Tool break detection

500 W Spindle: 60,000 RPM

Routing speed: 100 mm/sec

Positional speed: 1000 mm/sec

Windows based system platform

Low vibration vacuum pump with vacuum filter change alarm

Options:

FX5003 Fiducial mark vision system

Universal fixture and top clamp

Spare parts:

Connecting cable (6m) for 4041 spindle

Photo electric sensor

Photo micro sensor

Collet 1/8 for KAVO 4041 Spindle

Filter bags

Gas spring

Vacuum brush, 15 mm

2018 vintage.

GETECH GSR 1290 is a pc board assembly and manufacturing equipment designed to bring high efficiency and fast production output. This system makes the job of building circuit boards easier and faster than ever before. GSR 1290 can be used to produce small- to mid-size circuit board assemblies. It has a variety of components including a universal feeder unit, placement modules, a component handling machine, and a conveyor belt for transporting components. Its universal feeder can be configured depending on the component and volume requirements of your assembly. It has no delays for reloading between different feeders; this speeds up the process by eliminating time wasted on switching feeders for different components. The placement modules on GETECH GSR 1290 feature high-speed pick-and-place machines with accuracy down to 0.005mm, enabling higher throughput rates than ever before. This ensures that even delicate components are placed accurately. The clear vision tool and advanced robotics with its integrated digital image recognition eliminates human error. The component handling asset organizes the components, minimizing the chances of misplacing them or using the wrong parts. GSR 1290 operates on its own, with no operator required to be present. This ensures that the machinery runs with accuracy and reliability. Additionally, it has automatic error detection and self-correcting features that activate in case something goes wrong. This greatly reduces the risk of costly product reworks. The high throughput and repetitive accuracy of this model means that circuit board assemblies are produced in high volumes quickly and accurately. In addition to its production capabilities, GETECH GSR 1290 has comprehensive inspection functions. It can conduct a visible inspection of the assembly as well as a full BGA x-ray and infrared inspection. This ensures that everything is placed in the exact way according to the design specifications, and that all components are in working order. Overall, GSR 1290 is an efficient and powerful pc board assembly and manufacturing equipment that helps reduce labor costs, accelerate throughput, and increase production output. It is the perfect choice for those who need to produce small- to mid-size circuit board assemblies in the shortest amount of time. Designed with efficiency in mind, GETECH GSR 1290 eliminates the hassle of manual assembly and inspection processes, giving users the best in quality and production.

There are no reviews yet