Used GLENBROOK TECHNOLOGIES RTX-113 #9360979 for sale

URL successfully copied!

Tap to zoom

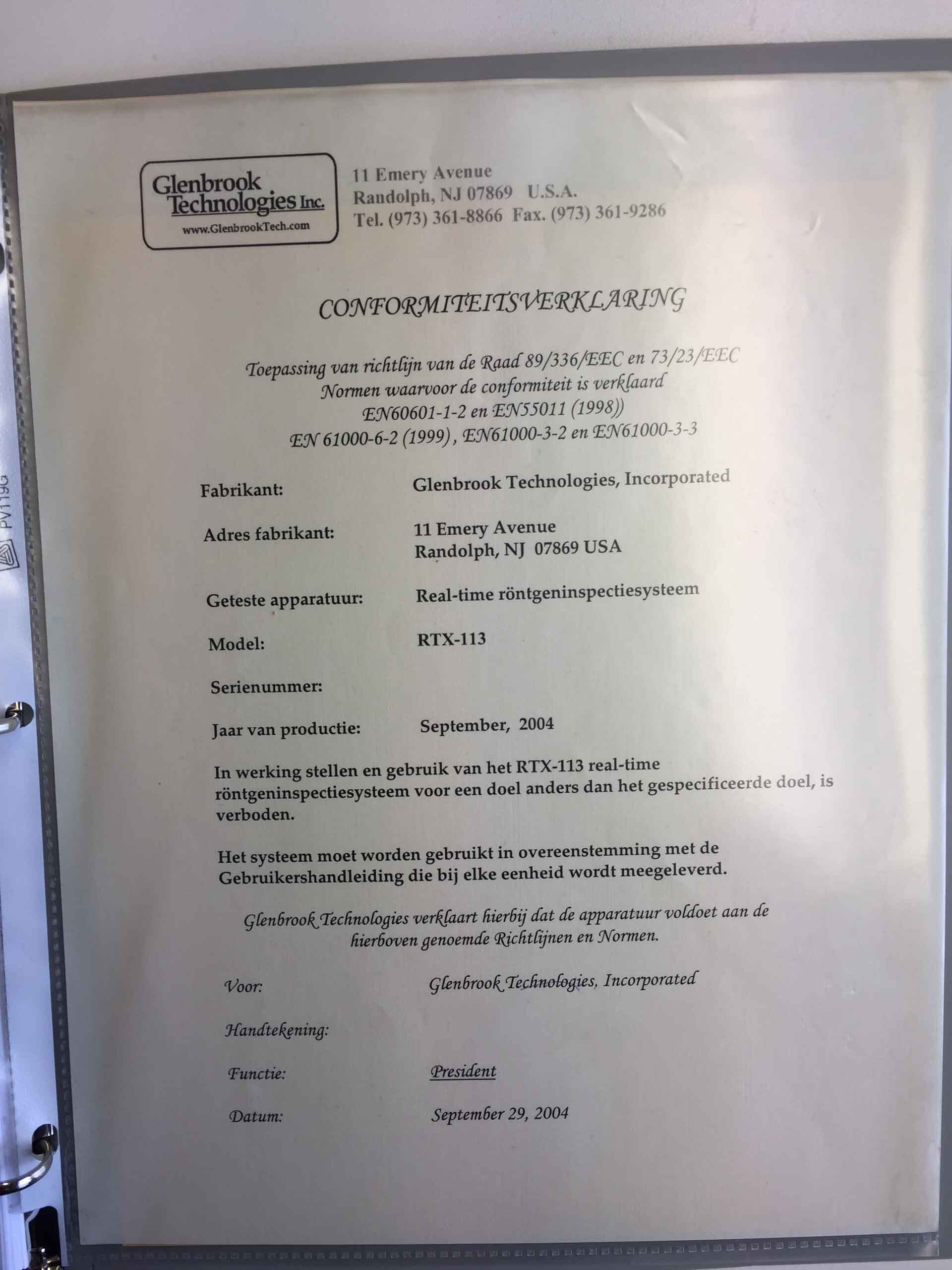

ID: 9360979

Vintage: 2004

X-Ray inspection system

User manual in dutch

2004 vintage.

GLENBROOK TECHNOLOGIES RTX-113 is a PC Board Assembly and Manufacturing Equipment, designed to help simplify and streamline the creation and manufacture of Printed Circuit Board (PCB) assemblies. It is designed to meet the needs of both small and large PCB manufacturing enterprises, and its features include: Assembly: GLENBROOK TECHNOLOGIES RTX 113 includes an automated assembly system with a combination of manual and automated components. It features loading and assembly stations, including auto-fluxing and component insertion, and a superior accuracy of 0.003"/0.0005 Degrees accuracy. Soldering: The Unit also features a variable-speed soldering conveyor using IR heating technology. It also includes auto-profile menu capabilities, on-site welding, and an adjustable PCB base plate. The machine is designed with safety in mind, including an enclosed welding station with redundant UVM safety curtains. Inspection: To ensure the highest quality of production, RTX-113 includes a precision inspection station with video image recognition. The tool also features an off-line quality control station with automated incoming inspection and automated 100% inspection prior to packaging. Other Features: RTX 113 also includes a variety of additional features designed to enhance the PCB assembly process, such as software for automation design, flexible material handling systems, and a variety of options for test interfaces. It also provides comprehensive technical support with a wide range of training and on-site installation services. In short, GLENBROOK TECHNOLOGIES RTX-113 is a comprehensive PC Board Assembly and Manufacturing Asset tailored to the needs of PCB manufacturers. It offers a variety of features intended to simplify and streamline the production of PCB assemblies, including automated assembly, soldering and inspection. It is designed to ensure a high level of accuracy and quality, and it provides a variety of features for test interfaces and flexible material handling to help make the entire PCB assembly process as efficient and cost-effective as possible.

There are no reviews yet