Used GPD Max Series #9202627 for sale

URL successfully copied!

Tap to zoom

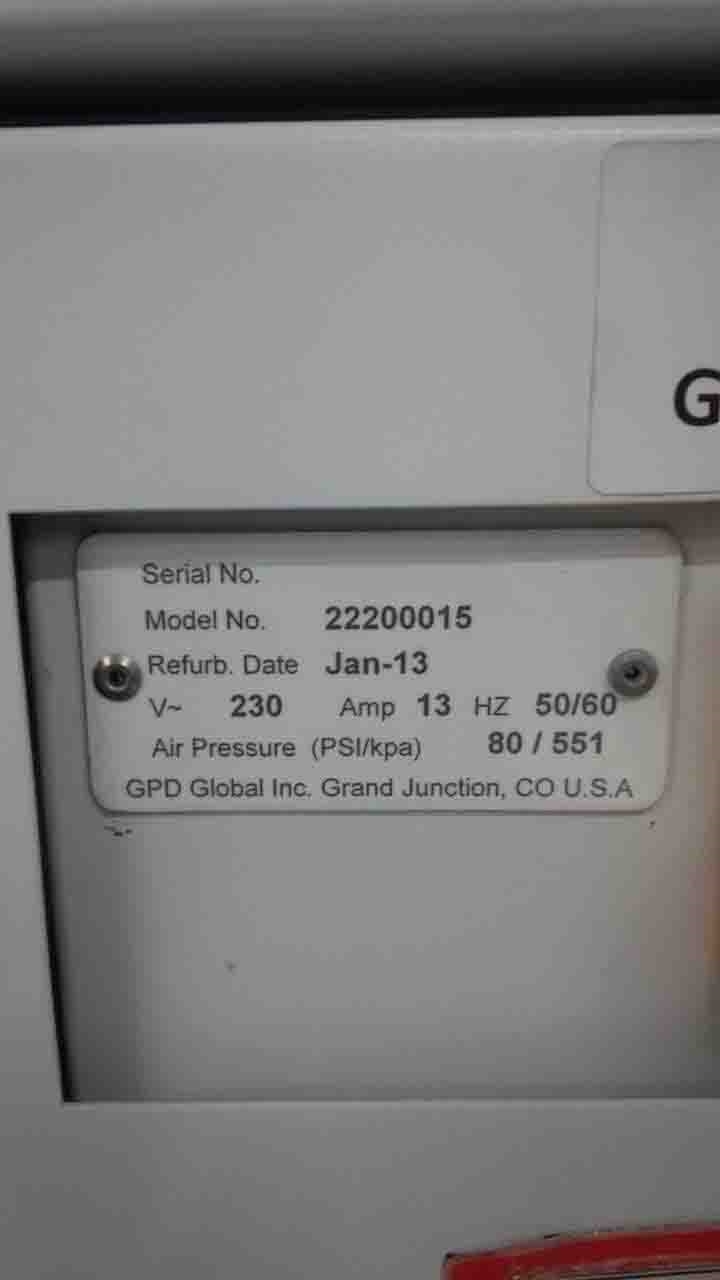

ID: 9202627

Dispensing system

Model no: 22200015

Jetting pump

Inline conveyor system / Stand-alone system

Dispense rate: 38000+ Dots per hour

Linear speed: 762 mm/second (3"/second)

Positioning accuracy: ±0.025 mm (±0.001")

Repeatability (Per axis): ±0.0152 mm (±0.0006”)

Z-Axis travel: 82.6 mm (3.25")

Resolution (Per axis): ±00051 mm (±0.0002)

Pump stations (Maximum): Up to 2 working pump mounts

Conveyor width adjust: 38 cm to 305 mm (1.5" to 12")

Ventilation flow rate (Per port): 7079 l/min (250 CFM)

Micromax P/N: 22200015

Air cap: 5cc, 10cc, 30cc

L Wrench set

Pipettes

Super lube with MSDS

Door keys: Triangle & square

(2) Computer removable drive keys

(5) Vaccum standoffs

(2) SMEMA Cables

(2) SMEMA Dummy plugs

Nozzle heads P/N: 2650-0041

(5) Cleaning wires, 0.18mm P/N: 10/4713

Level detect PIEZO SYSTEMS valve 3200 with heat P/N: 22293076

(5) Standoff assemblies, spring compliants P/N: 22295053

Probe tip

Air pressure: 552 kPa (80 psi)

Air flow rate: 113 l/min

Power supply: 120 V / 230 V, 50-60 Hz.

GPD Max Series is a pc board assembly and manufacturing equipment designed with the mission of providing customers with comprehensive solutions for the assembly of printed circuit boards (PCBs). It is a highly accurate and user-friendly system, providing material handling, placement and soldering capabilities for a wide variety of PCB components. Max Series is capable of meeting all the requirements for high-precision production in both manual and automated operations. GPD Max Assembly Unit consists of GPD Max Placement Machine, a high-speed precision equipment with an advanced tooling head for placement and soldering of components. It features a flexibly mounted tooling head, allowing the operator to quickly and easily transfer components from the front to the back of the assembly panel. The placement accuracy of the machine is up to 12 mils, providing superior accuracy for assembly of high-density PCBs. Additionally, GPD Max Placement Machine features an onboard vision tool for quick and accurate component identification and positioning, making it perfect for automated operations. GPD Max Soldering Machine is also part of GPD Max Assembly Asset, making it possible to carry out soldering operations directly on the board. The machine is equipped with an onboard point-to-point soldering model, ensuring precise and reliable soldering processes. It is also compatible with a variety of soldering materials, so it can be used for both lead-free and leaded soldering processes. Furthermore, GPD Max Soldering Machine guarantees high speed soldering, with the capability of soldering up to 8,000 components per hour. GPD Max Series is equipped with comprehensive control software, offering easy and flexible manipulation of the assembly parameters, including component heights, materials and panel sizes. It provides complete visual feedback on the progress of the soldering and placement process and allows the user to customize the process for different components and assemblies. In combination, GPD Max Placement and Soldering Machine and GPD Max Assembly Software provide a comprehensive tool set for assembly of high-quality PCBs. These systems are designed for maximum accuracy and reliability, and Max Series has been rigorously tested to meet all customer expectations. This equipment provides an efficient and cost-effective solution for the assembly of PCBs.

There are no reviews yet