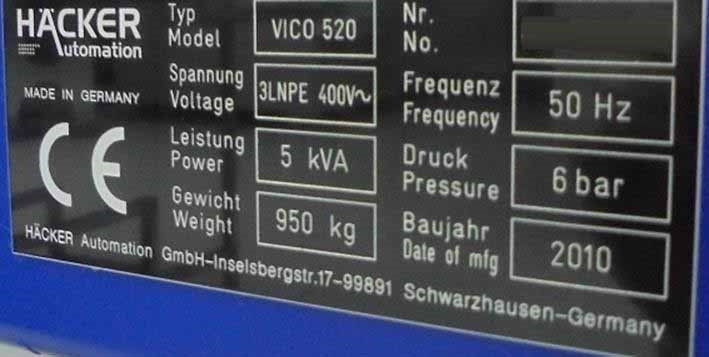

Used HACKER AUTOMATION VICO 520 #9192149 for sale

URL successfully copied!

Tap to zoom

ID: 9192149

Vintage: 2010

Pick and place machine

Signal tower

Substrate holder, 4"

3D Imaging

Cameras from, 8" wafer to tray

With FS20-2 flip station

CE Marked

2010 vintage.

HACKER AUTOMATION VICO 520 is a PC Board Assembly and Manufacturing equipment that is designed to streamline the process of designing, creating, and assembling PCBs. This system utilizes innovative technology such as automated solder paste deposition, component placement, reflow soldering, and optical inspection processes. VICO 520 has an open platform that is customizable to fit the customer's requirements and can be used for a range of applications such as prototype manufacturing, short-run production, and batch production. Its flexibility allows for a variety of configurations to be created to fulfill specific customer needs. HACKER AUTOMATION VICO 520 features an advanced optical vision unit to inspect components before they are assembled onto the board in order to ensure that the products are of the highest quality. This machine is capable of sensing the parts with great accuracy and can detect on-site defects or flaws before they are soldered onto the board. In addition, VICO 520 features advanced solder paste deposition technology to ensure quick and accurate application of paste of to the surface of the PCB. The dependable reflow soldering process ensures that all components are accurately soldered onto the board to create a high-quality finish. In order to make the PCB assembly process easier and quicker, HACKER AUTOMATION VICO 520 also features a user-friendly user interface. This allows the users to easily enter all the information related to the design into the tool. The asset also comes with a built-in PC software package that helps to configure the settings and provides an overview of the production process. Overall, VICO 520 is an ideal solution for businesses that require a reliable, efficient, and cost-effective solution for PCB assembly and manufacturing. Its robust features make it the perfect choice for companies that create PCBs in large quantities, as they can benefit from the improved speed and accuracy that the automation processes bring to their production line.

There are no reviews yet