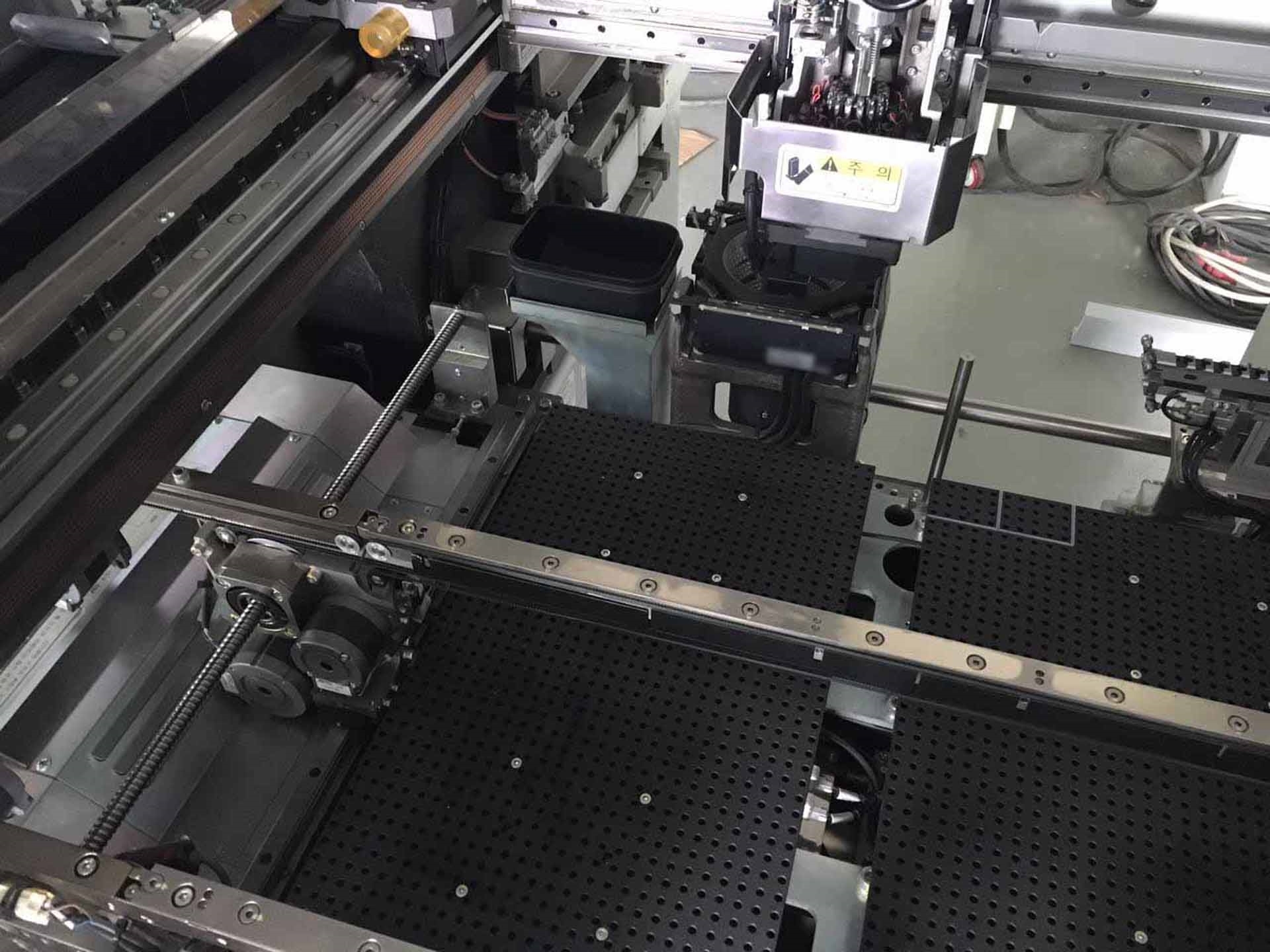

Used HITACHI Sigma-G5 #9208921 for sale

URL successfully copied!

Tap to zoom

HITACHI Sigma-G5 is a PC board assembly and manufacturing equipment designed using advanced technology that make it a competitive choice for electronics manufacturers. This system features a multi-head placement head unit with a 6-axis high-speed servo motion, making it an ideal choice for high throughput production lines. Sigma-G5 also includes a totally integrated vision machine that records each component's placement location and orientation, making it ideal for high accuracy placements. This tool features a total of 4 heads, each with up to 12 nozzles per head, with a maximum total of 48 nozzles. HITACHI Sigma-G5 also has laser centering sensors that are used to align the components on the PC board, which helps to ensure that the parts fit perfectly with each other. Sigma-G5 features a high-speed conveyor mechanism that can handle up to 100 boards per hour, and an inline optoelectronic router that enables efficient routing. In addition, optional Multi-Conveyor feeders are also available, for improved board handling efficiency. Furthermore, HITACHI Sigma-G5 can be used for pick and place of odd form components, such as connectors, IC chips, etc, allowing for flexible and cost effective board assembly. This asset also features high speed detection technology to ensure that components are correctly placed, and a wide range of components can be placed at high speed, including specialty components such as BGAs and MLPs. Sigma-G5 has a very user-friendly graphical user interface, and offers an extensive range of diagnostics and maintenance at all levels of the model. A comprehensive suite of programs is also available to customize and control the equipment. HITACHI Sigma-G5 can also be integrated into existing networks and other systems for even more convenience and control. Sigma-G5 is a reliable and highly efficient system that is perfect for electronics manufacturers who need incredibly accurate and high speed placement solutions. With the ability to process up to 100 boards per hour, this unit can output an impressive amount of completed boards to fulfill the demands from customers. Its wide range of features and functions also make it versatile enough to handle different types of components and boards, making it an excellent choice for any electronics manufacturing situation.

There are no reviews yet