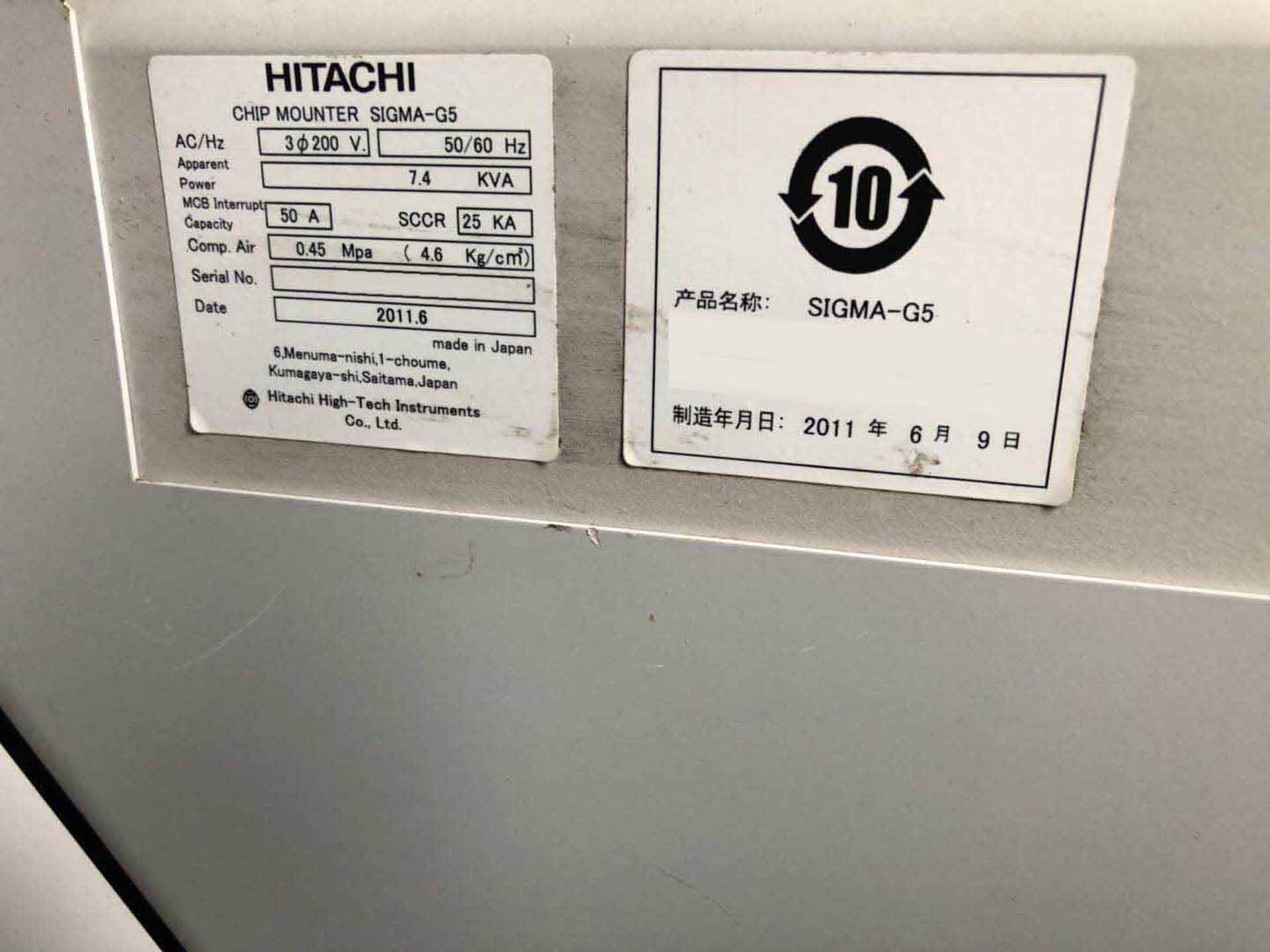

Used HITACHI Sigma-G5 #9208933 for sale

URL successfully copied!

Tap to zoom

ID: 9208933

Vintage: 2011

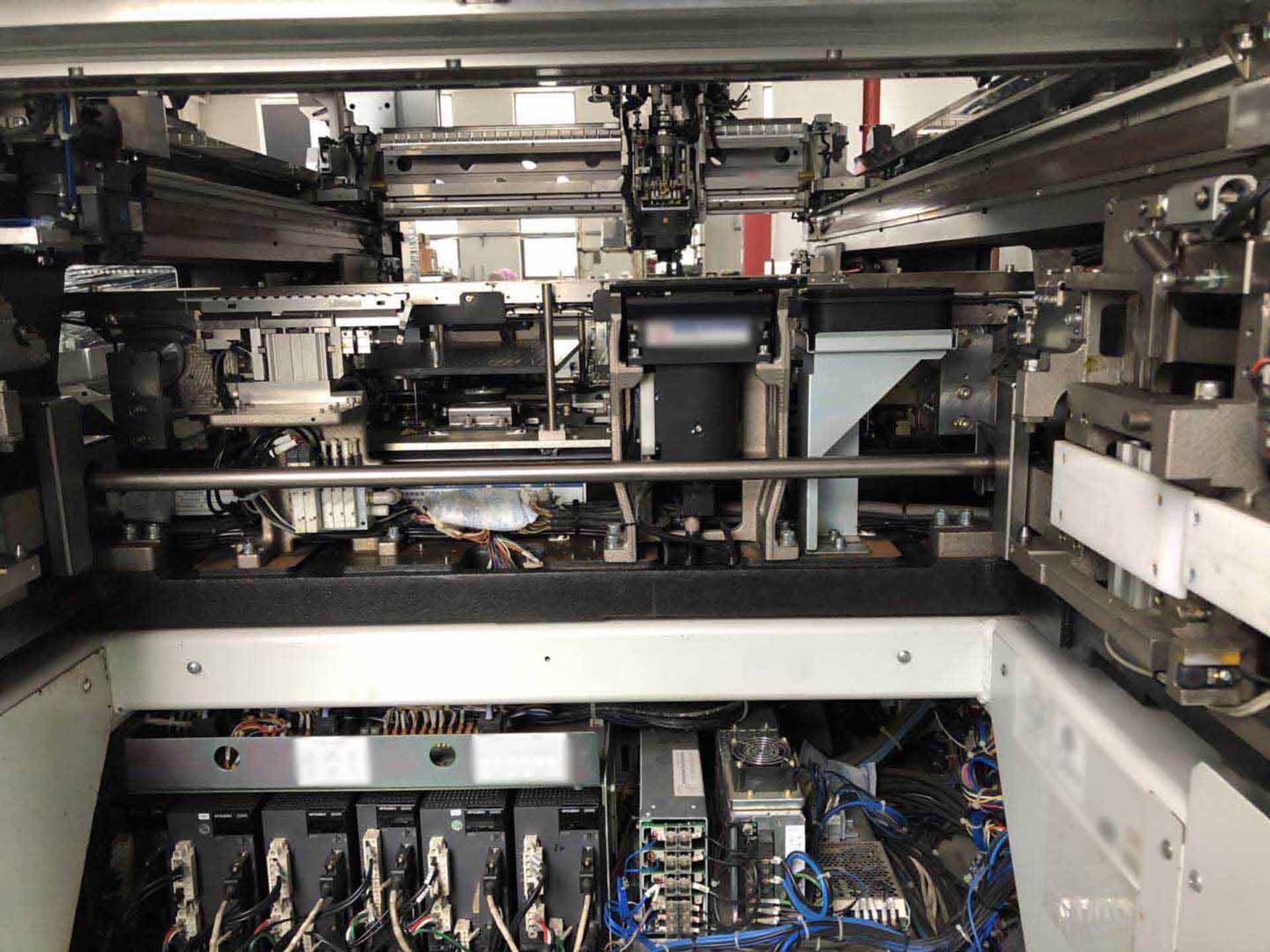

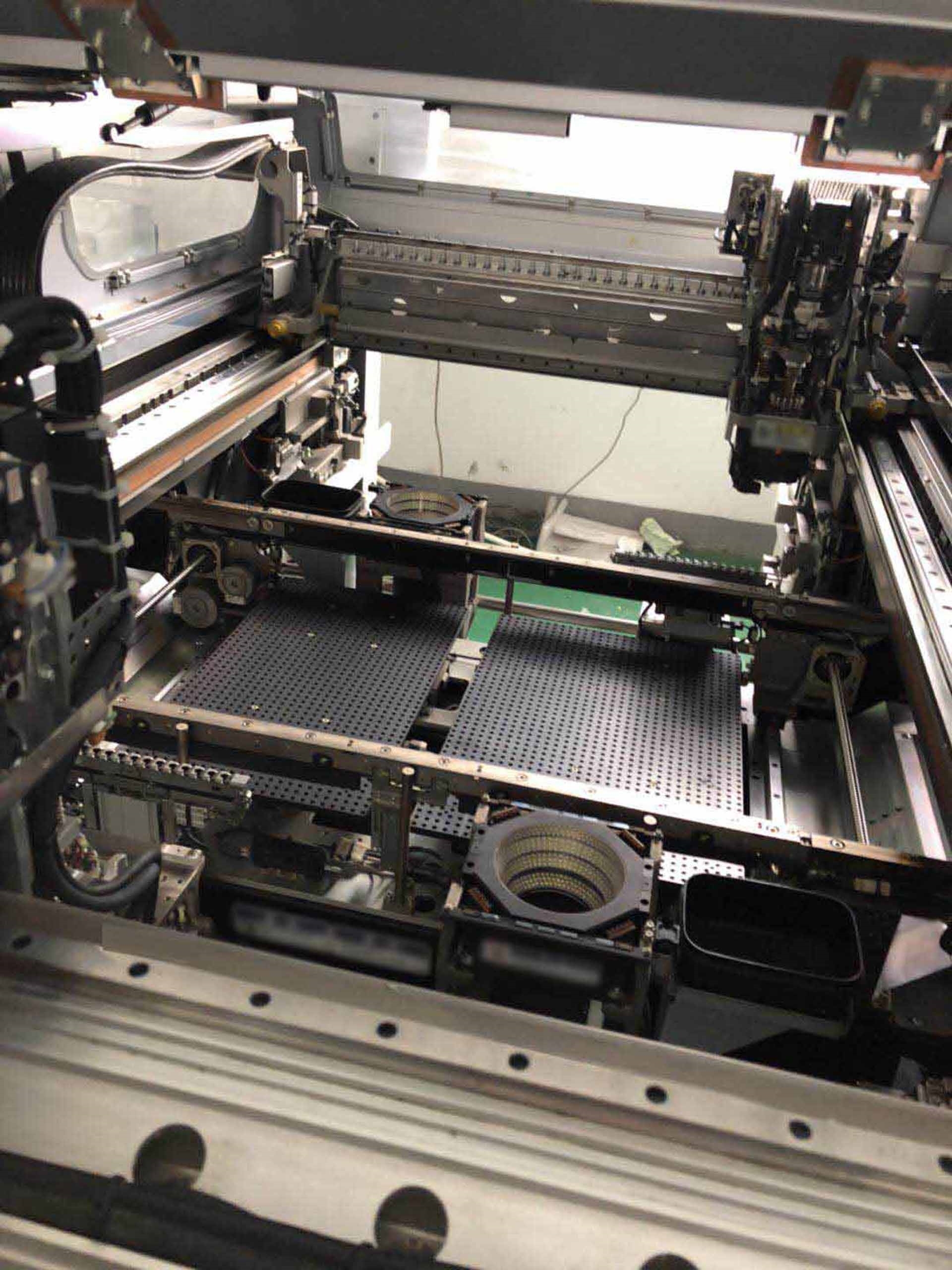

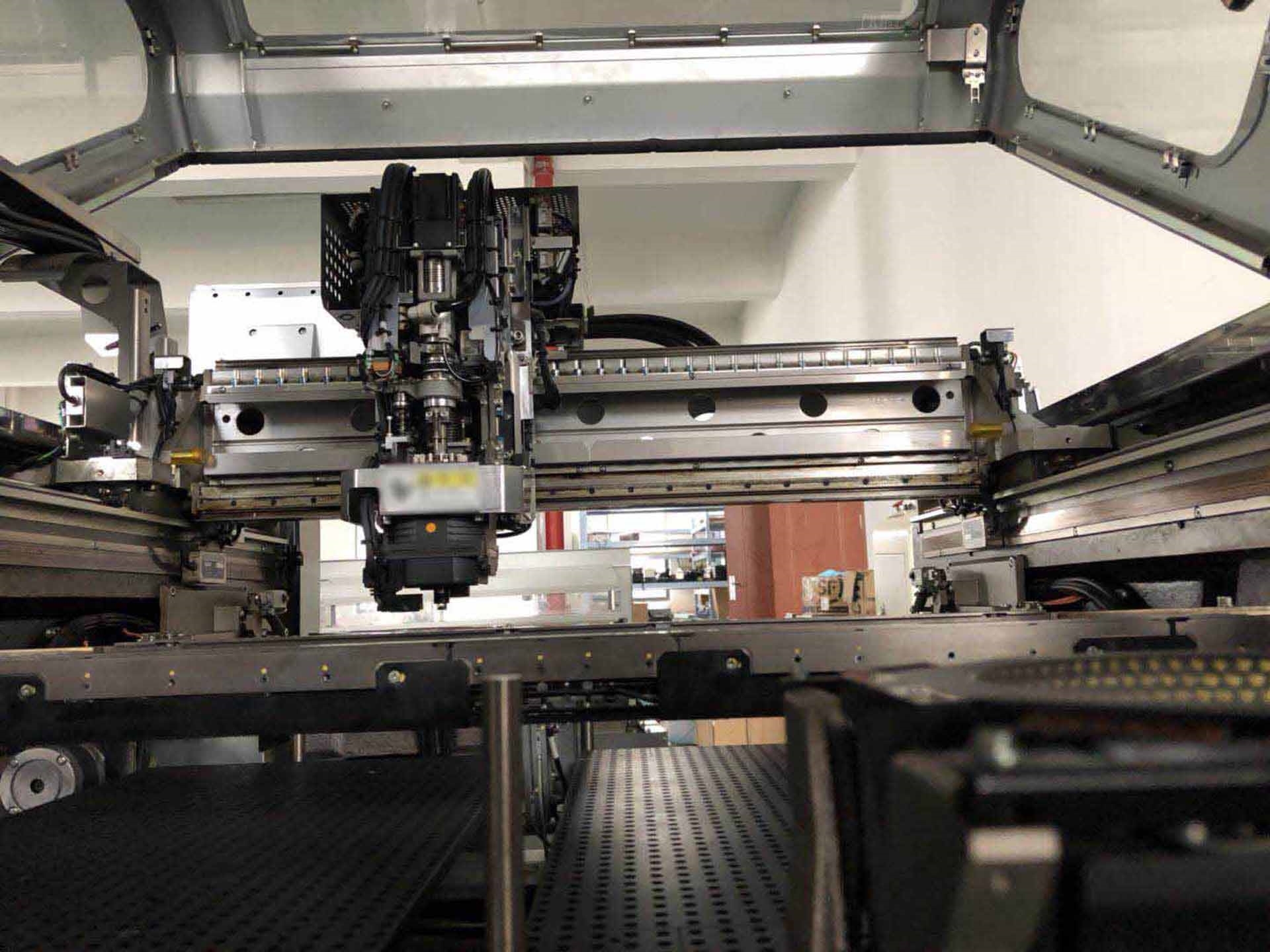

Chip mounter

(2) Heads

(2) Fixed cameras

(2) Mark cameras

2011 vintage.

HITACHI Sigma-G5 is the latest addition to their series of pc board assembly and manufacturing systems. For users and manufacturers this benchtop model offers a powerful, yet economical solution to prototyping, surface mounting, and inspection of printed circuit boards (PCB). Sigma-G5 equipment features a lightweight body that allows for easy transportation between different workspaces. The system can accommodate a wide variety of PCB sizes ranging from 2.5 cm x 3 cm to 25 cm x 30 cm, making it suitable for a variety of applications. Additionally, the unit features a five-step stencil printing process to ensure precise and accurate results. HITACHI Sigma-G5 features HITACHI advanced vision alignment machine which utilizes both line-insertion and edge recognition to ensure board placement accuracy. This tool also features a semi-permanent mounting device that makes setup and changeover times much faster. The asset boasts a cycle time of less than 10 seconds per board that allows it to easily meet production requirements. Sigma-G5 comes with two divisions - the pick-and-place division and the soldering unit. The pick-and-place division is a fully-automated machine that can place a variety of components ranging from 0.5mm to 55 mm. This can be done at a high speed of 2,000 components per hour. The machine also comes with a built-in laser vision model that can identify components no matter their shape or size. This equipment can even identify components with skewed shapes which is a difficult task for traditional pick-and-place machines. The soldering unit features both Hot Bar soldering and through-hole soldering capabilities. The Hot Bar unit offers high temperature soldering and is capable of soldering components up to 0.4 mm in size. The Through-Hole unit can accommodate components up to 10 mm in size. In addition to offering a robust production solution to manufacturers, HITACHI Sigma-G5 is modular in design which allows for easy maintenance and repair. The system comes with a host of user-friendly features such as a touch screen monitor for easy visual feedback as well as a programmable logic controller (PLC) to help reduce the learning curves of using the unit. In conclusion, Sigma-G5 is a versatile and user-friendly pc board assembly and manufacturing machine. It is capable of meeting a wide variety of production demands and can easily accommodate a variety of PCB sizes. The tool features both pick-and-place and soldering capabilities with a built-in vision alignment and laser identification technology. HITACHI Sigma-G5 can easily meet the speed and accuracy requirements of today's production lines.

There are no reviews yet