Used HRT TECHNOLOGY / HERRETT HLEA 6B11 #293653849 for sale

URL successfully copied!

Tap to zoom

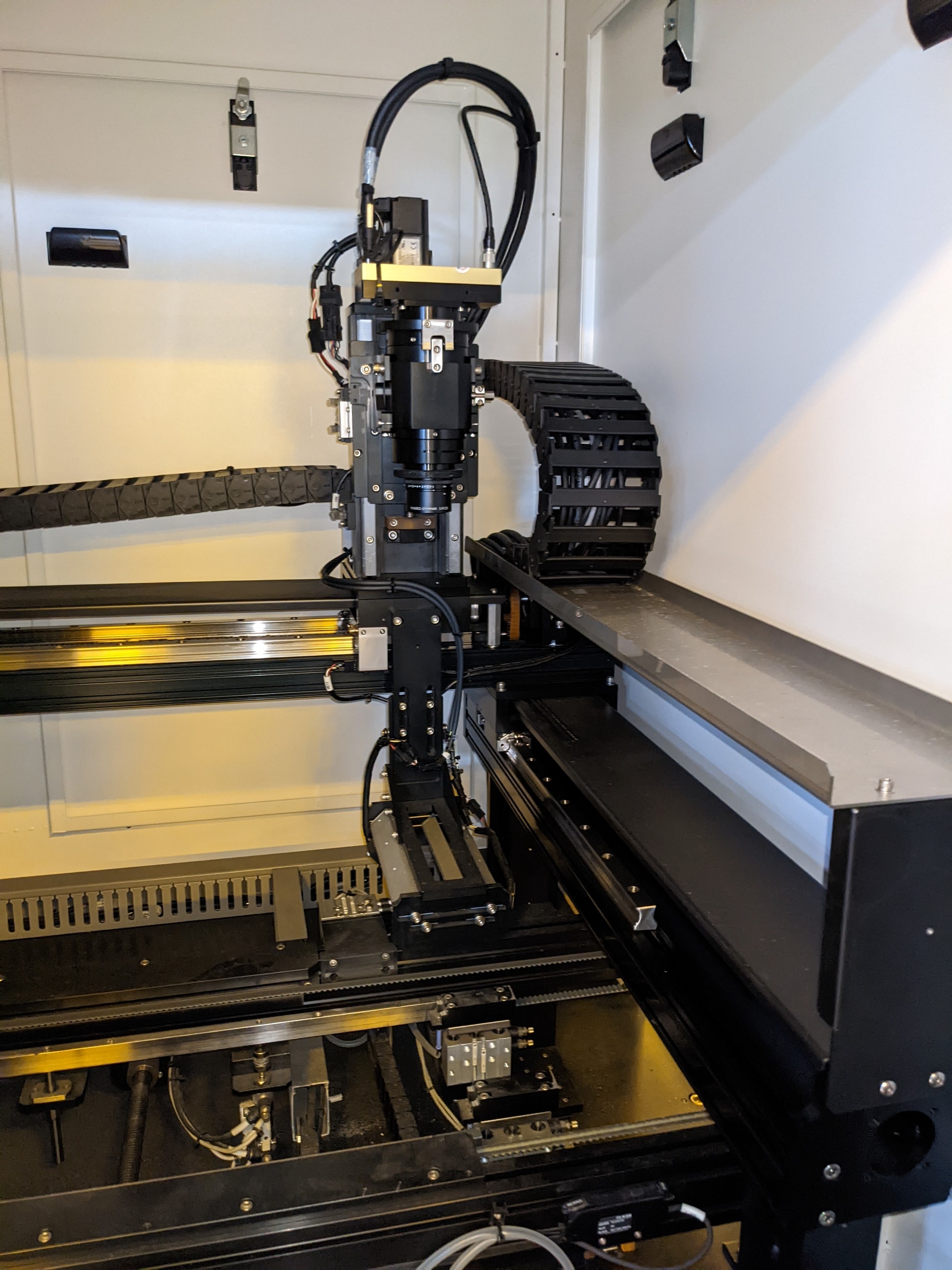

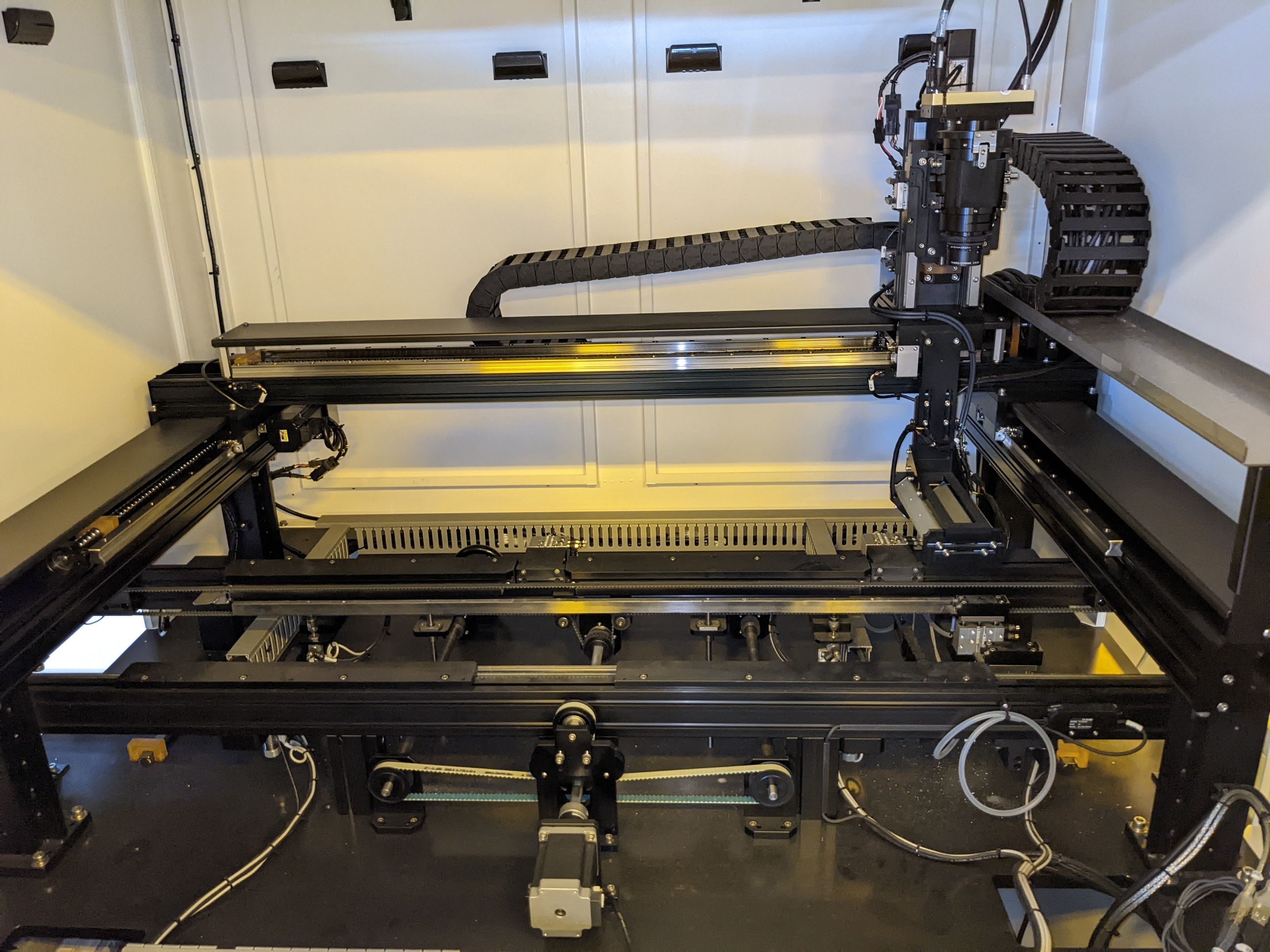

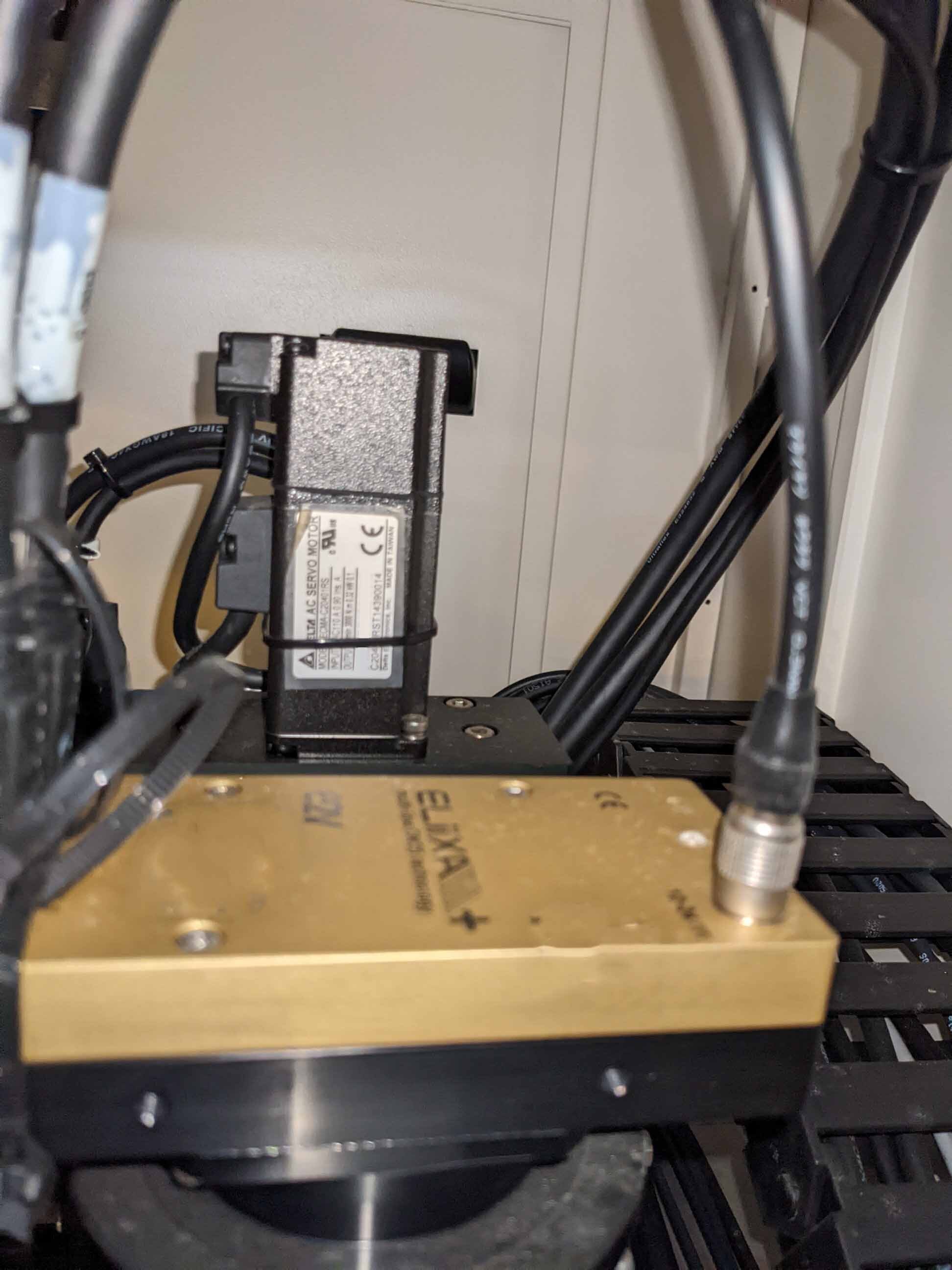

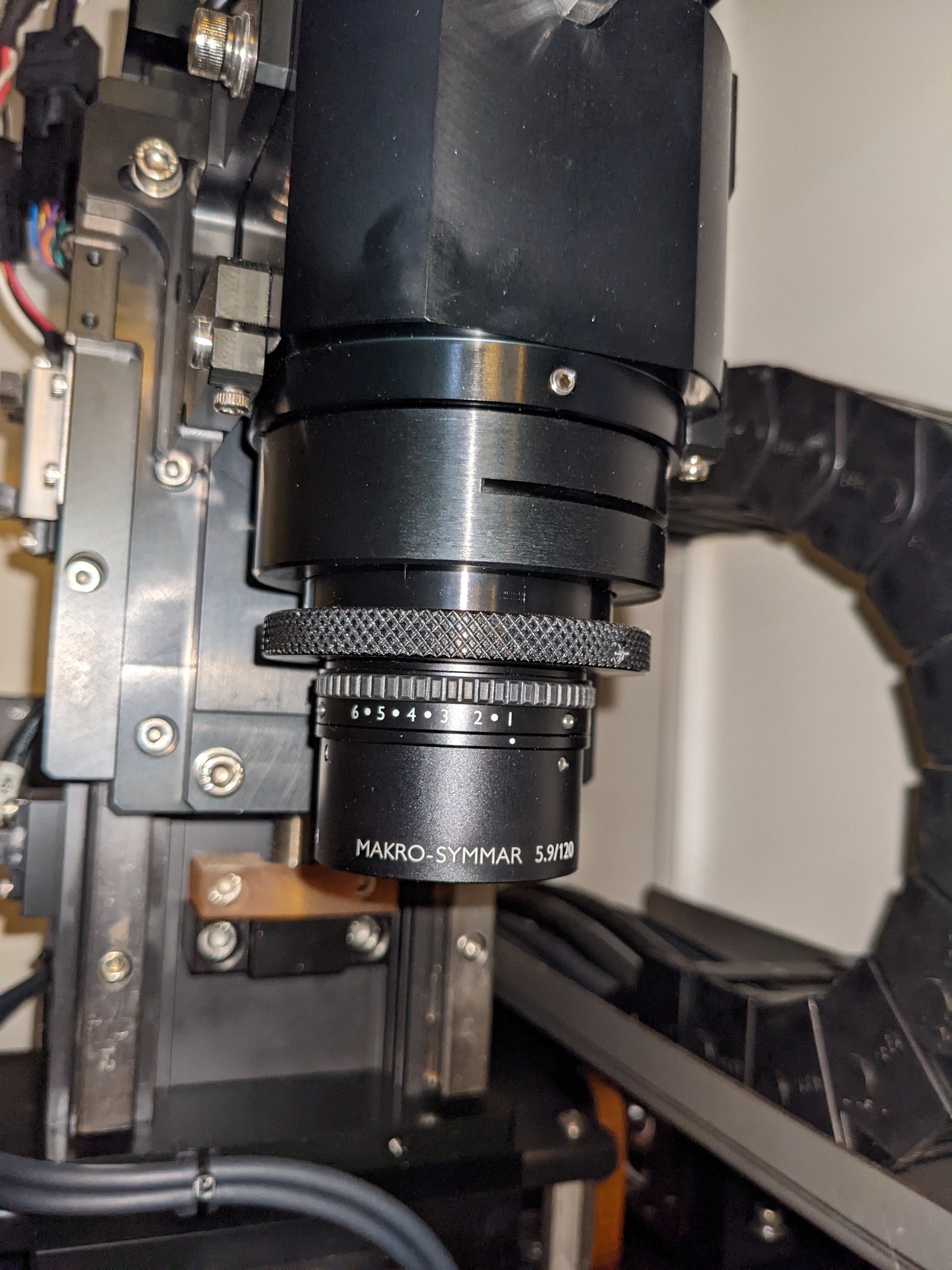

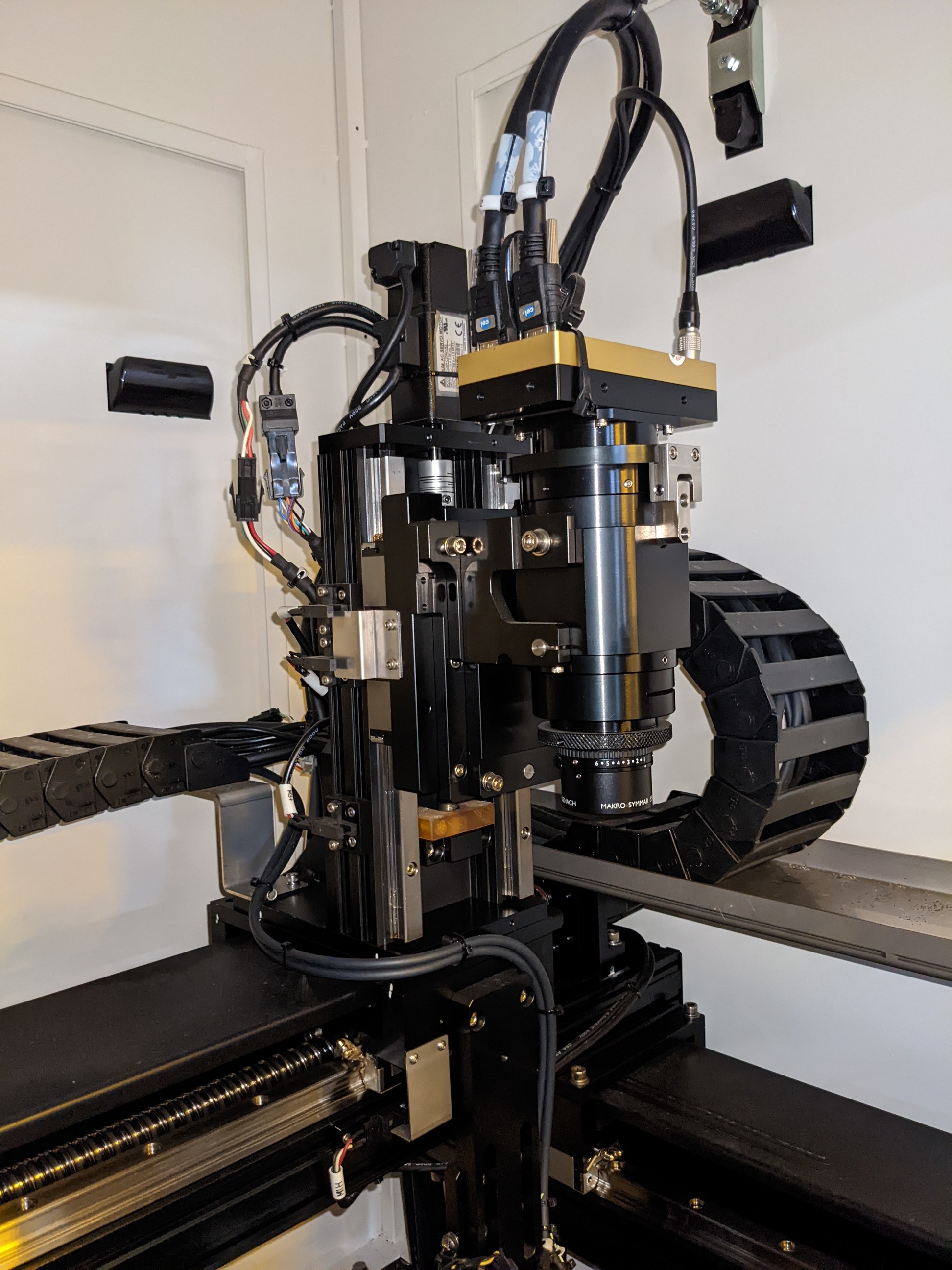

HRT TECHNOLOGY / HERRETT HLEA 6B11 is a PC Board Assembly and Manufacturing Equipment from Heritage Retronics Technology (HRT). This system is designed to provide the highest level of quality, reliability and performance for the production of PC Boards. The unit consists of a variety of components including a control board, a high-speed pick and place unit, a high resolution camera machine, a stencil printer, an oven for soldering and a board routing tool. The combination of these components enables the production of high-quality printed circuit boards in a timely and cost-effective manner. The Control Board is used to control the machine and is comprised of a Motherboard, IO Board and Display. The Motherboard controls the overall operation of the asset including the communication and data transfer between the Pick and Place, Camera Model and Printer. The IO Board is responsible for the management of protective software, machine positioning, and calibration of all equipment components (including temperature control). The Display offers real-time monitoring of the machine's status and can be used for programming and debugging. The Pick and Place component of the HRT HERRETT HLEA 6B11 is a high-speed unit capable of moving components from one position to another with accuracy and speed. It is equipped with a pick and place head, nozzle, guide rail and collection unit. The Pick and Place unit is specifically designed to accept tall components and also features a component recognition system. The high-resolution camera unit is designed to give users detailed visual feedback regarding the placement of components on the board. This machine allows users to precisely inspect each component prior to placement and adjust the component positions quickly and easily if necessary. The Stencil Printer is used to transfer the patterns onto the board prior to component placement and solder reflow. The high-quality prints help ensure a high-level of precision and accuracy. The Oven is used to apply heat to the parts after they have been placed and soldered in order to ensure that the connections are reliable. To ensure proper solder connections, the machine is equipped with a temperature control tool. The Board Routing Asset is used for routing the board after component placement and soldering. This allows for more complex wiring patterns and helps to improve the overall manufacturing quality. The Router is equipped with several interchangeable tools for optimal performance. To ensure maximum reliability, the HRT HRT TECHNOLOGY HLEA 6B11 is backed by a comprehensive warranty and is filed with parts, accessories and supplies for further customization. This model is able to handle heavy workloads and offers superior production speeds, making it the ideal choice for PC Board assembly and manufacturing.

There are no reviews yet