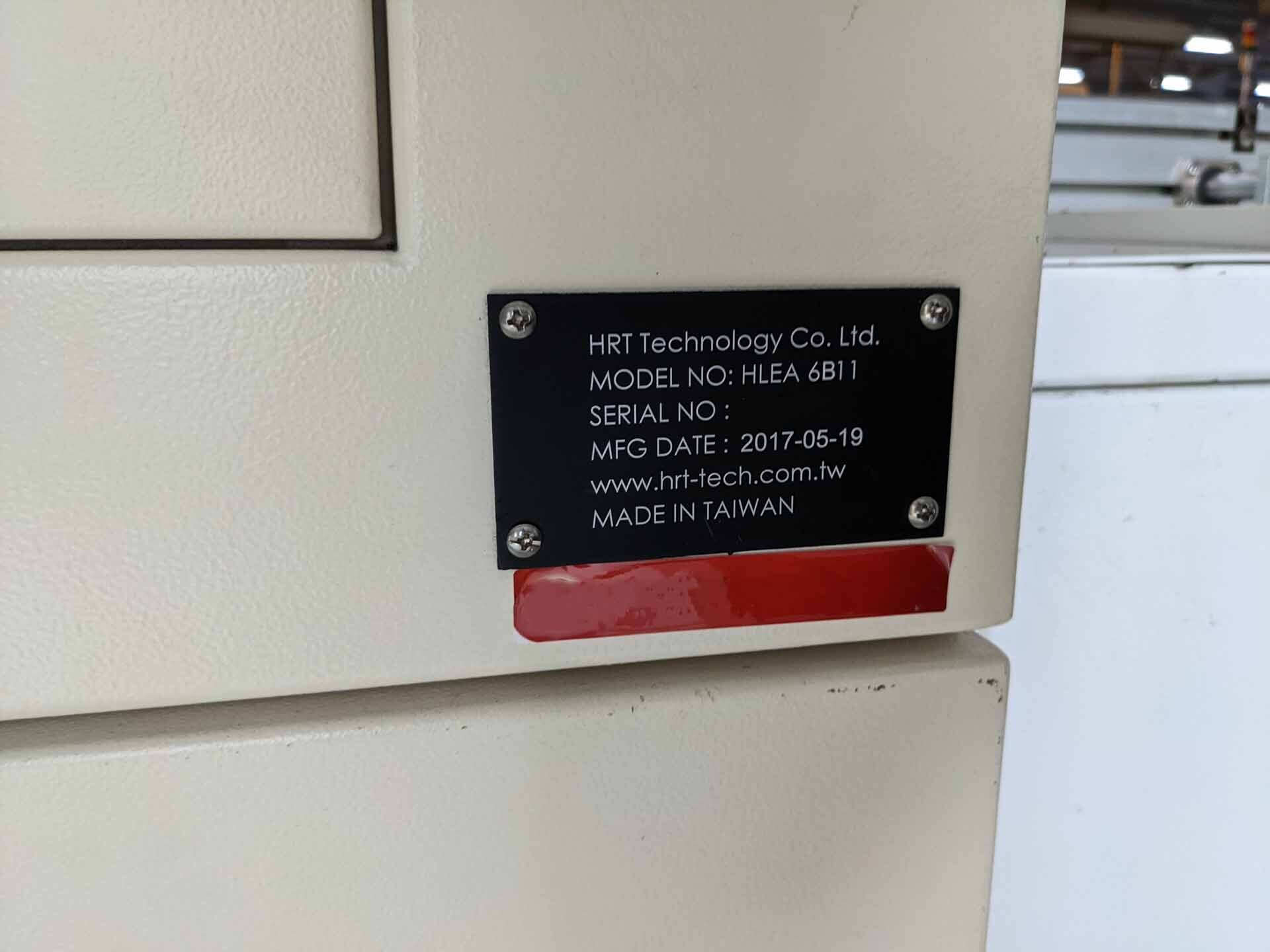

Used HRT TECHNOLOGY / HERRETT HLEA 6B11 #293653853 for sale

URL successfully copied!

Tap to zoom

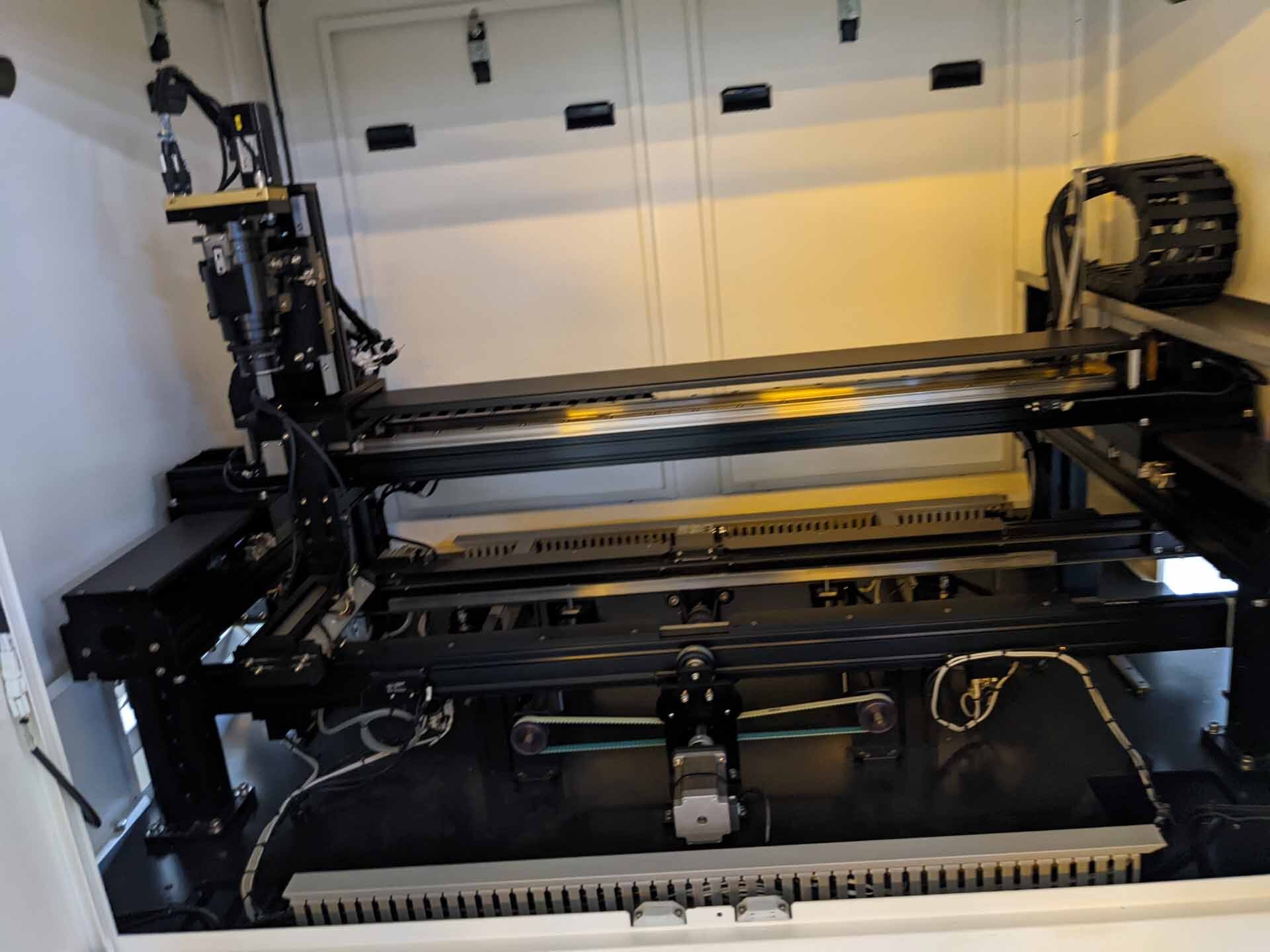

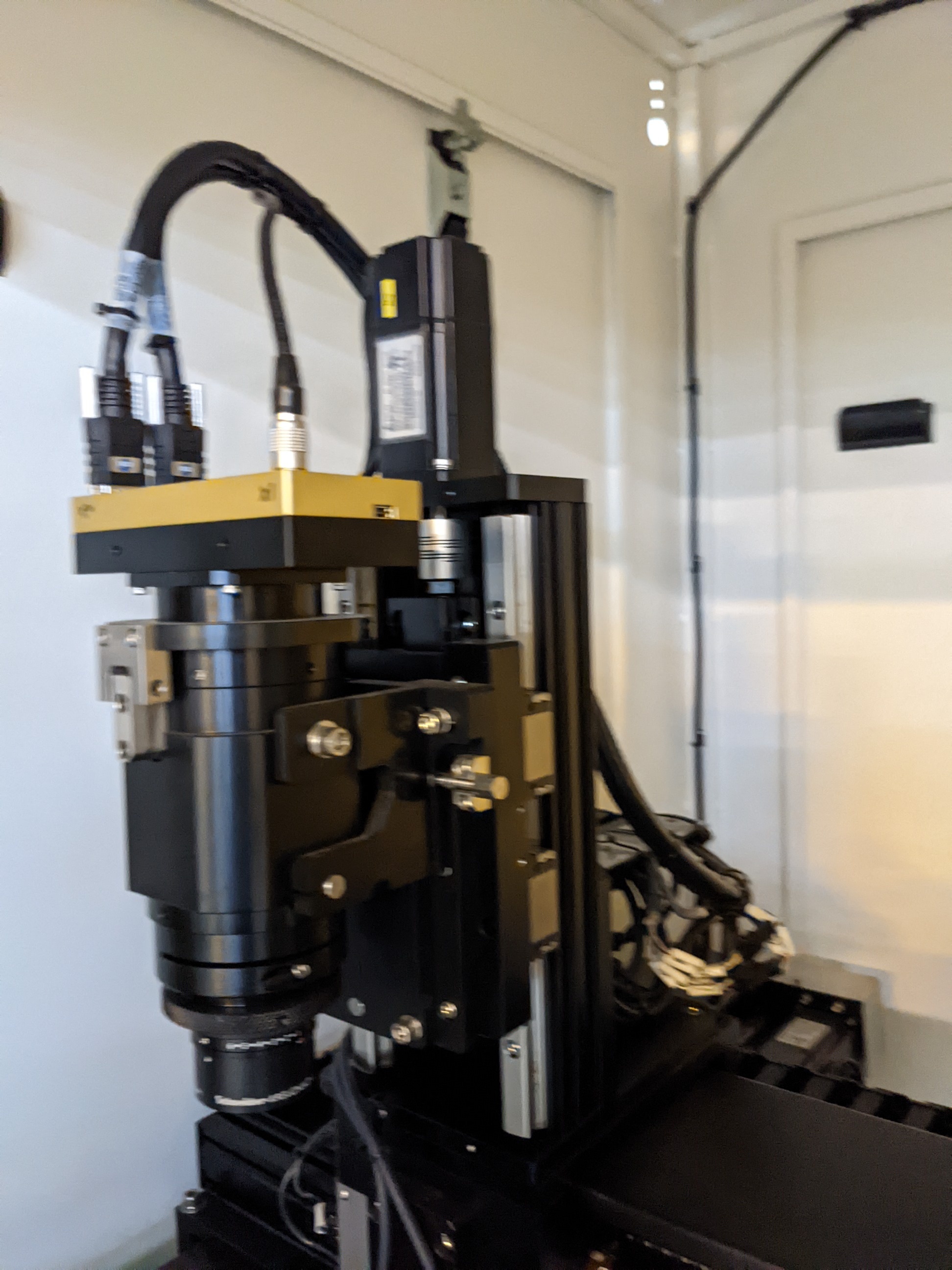

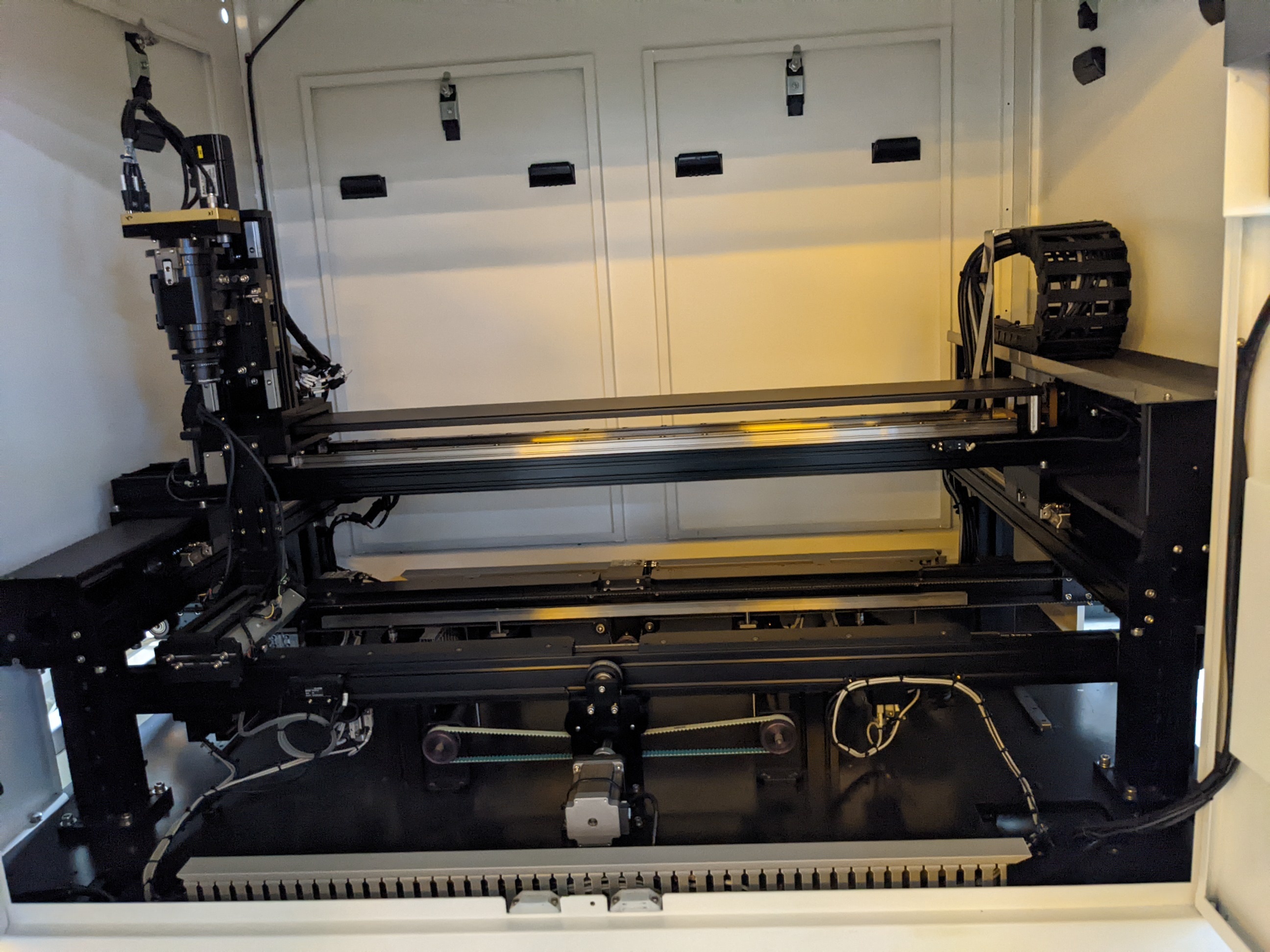

HERRETT is a PC Board assembly and manufacturing equipment designed by HRT TECHNOLOGY Engineering to meet the needs of high-volume assembly operations. The system is an integrated solution for custom board configurations with an emphasis on per-board quality and performance. The HERRETTE 6B11 includes multiple features and modules to improve assembly line productivity and efficiency, reduce potential defects in components, and increase quality assurance for the final product. The HERRETTE 6B11 unit is designed to automatically assemble PC boards at high speeds. It is powered by a 4th generation high-speed core processor and automated board handler, which can both handle large board work-loads. The machine is designed to provide full support of the IPC-A-610e standard and it meets the needs of automated lead-free solder processes. The 6B11 has full support for both air and liquid flux processing, which minimizes rework caused by flux residue. The HERRETTE 6B11 PC Board assembly and manufacturing machine is equipped with a high-resolution vision tool that is used to detect and identify components before and after the pick-and-place process. This ensures that there are no components placed in the wrong positions, thus avoiding mechanical jams and potential costly repairs. The asset is capable of multiple board sizes and configurations, with the use of a centering guide. This further increases accuracy and accuracy across different types of boards. In addition, the HERRETTE 6B11 model includes an integrated process failure detection equipment. This system monitors and inspects the process at key points during the assembly process and takes immediate action when a problem is detected, such as stopping the pcb production line, while the issue is addressed by skilled technicians. This helps ensure quality and high yields. The HERRETTE 6B11 unit also includes an automated optical inspection (AOI) machine that performs a scan of each PC Board after assembly, looking for any discrepancies in appearance or performance. The tool is designed to rapidly detect soldering issues, incorrect component placement, and other errors that might otherwise be time consuming or costly to address. The asset is fully remote controllable, meaning that even experienced technicians can adjust the model remotely to meet their specific needs. The HERRETTE 6B11 is a customizable and valuable tool for those companies who want to achieve high quality, high-volume board assembly operations. It is designed to reduce labor intensive work and minimize potential production defects or quality issues, making it a reliable and cost-effective tool for assembling PC Boards.

There are no reviews yet