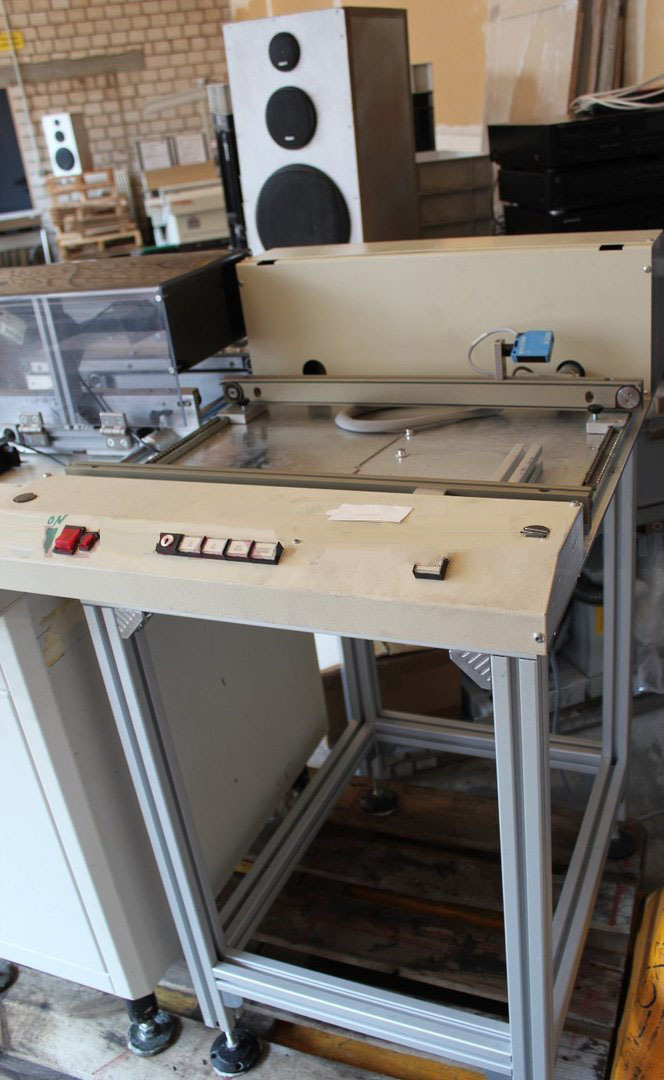

Used IPTE MTU #9153083 for sale

URL successfully copied!

Tap to zoom

IPTE MTU is an innovative pc board assembly and manufacturing equipment designed for flexibility and ease of use. This versatile system has the ability to work with a variety of board sizes and components. With MTU, a single machine can be used to convert from a multitude of different SMT processes such as pick and place, solder/de-solder, jet solder, and point-to-point. This allows board designs to be quickly adapted to customer needs without the need for dedicated machines. The machine can also be configured with a wide range of peripheral equipment, including loaders, unloaders, vision systems, and a variety of feeders for components that range from 0201 to 16mm. IPTE MTU also comes equipped with a built-in line balancing unit which ensures that the workload is distributed efficiently within the line. Another great feature of this machine is the optional AwaSys software suite, which provides real-time data monitoring and tracking capabilities. This ensures that each board is produced with the same high quality and repeatable results, as well as helping to detect potential errors or issues before they become a problem. The software can also be deployed within a lean manufacturing environment which further ensures a smooth and efficient workflow. MTU also has a high-end industrial control tool which is designed for top-level process control and reliability. With the use of safety-rated components, the asset is designed to operate without interruption and prevent any potential hazards or delays from occurring. Experienced technicians can also utilize the integrated elements to quickly and effortlessly program the model for a wide range of products. The user-friendly design of IPTE MTU also allows for easy maintenance and repairs. This allows factory staff to quickly and efficiently repair any issues, instead of relying on costly external service technicians. In summary, MTU is a comprehensive pc board assembly and manufacturing equipment that is designed for maximum flexibility and efficiency. With its advanced features, the system can be easily adapted to address a wide range of customer needs and production requirements.

There are no reviews yet