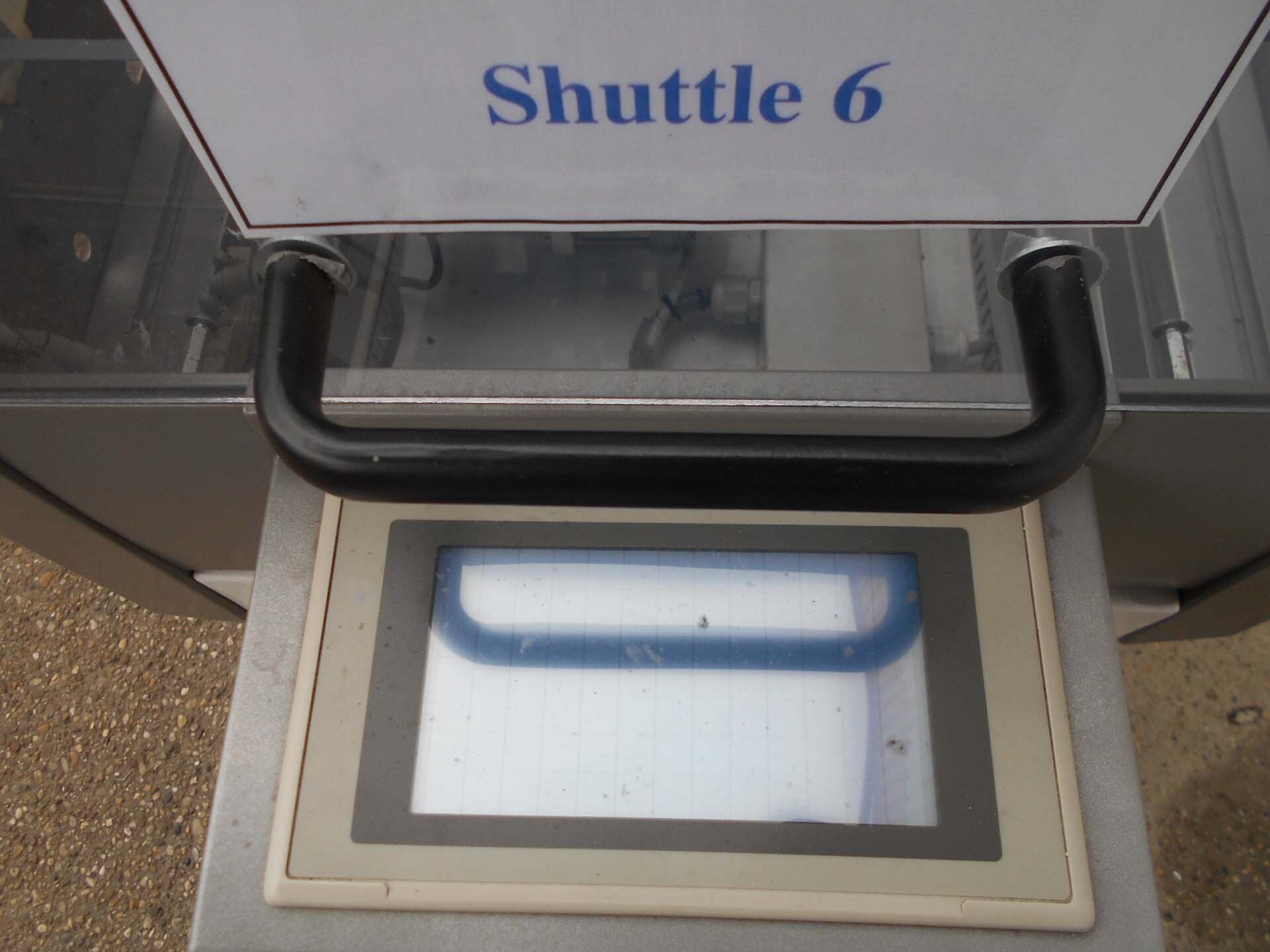

Used JOT AUTOMATION J208-50.0 #9383206 for sale

URL successfully copied!

Tap to zoom

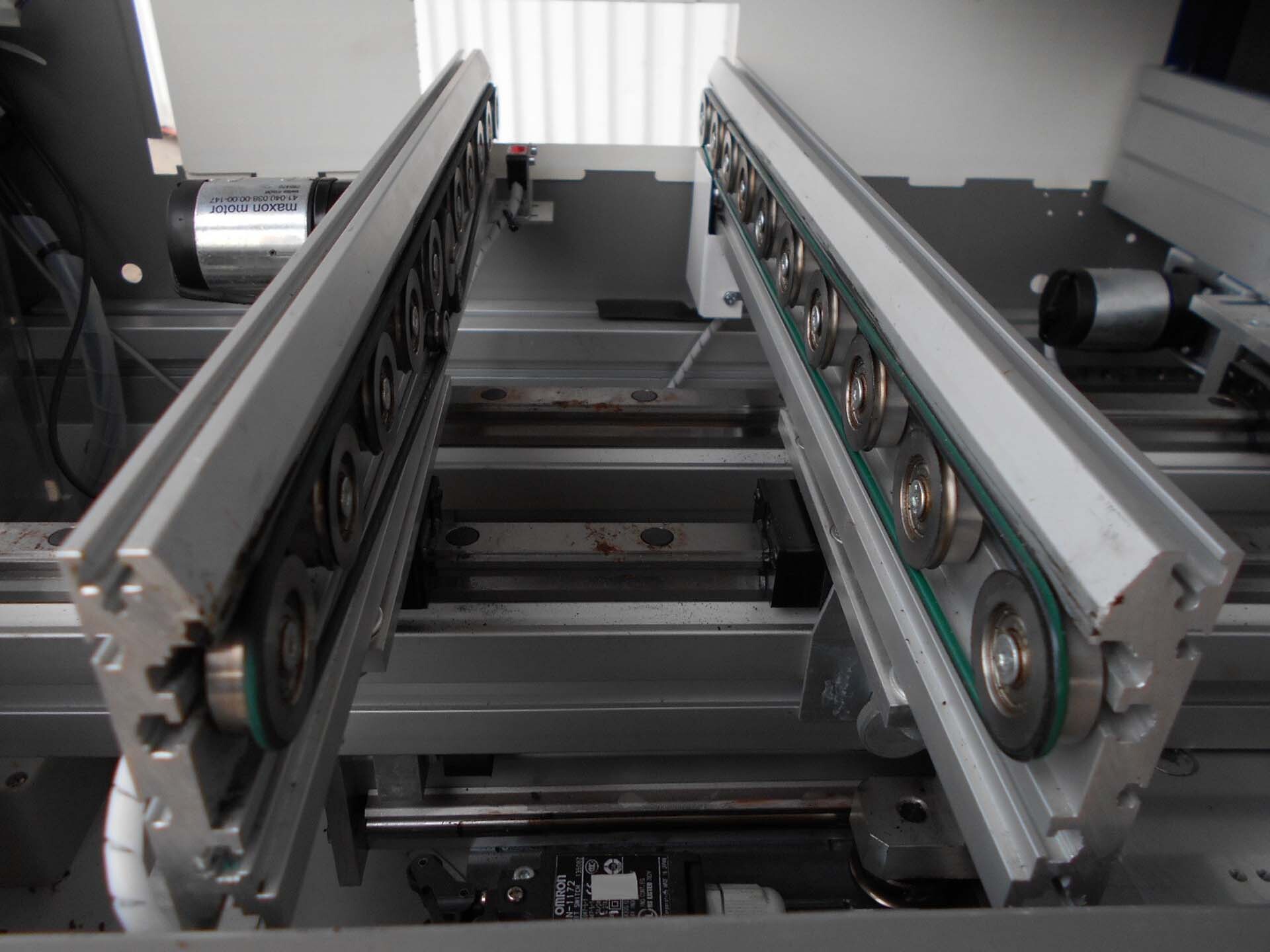

JOT AUTOMATION J208-50.0 is a versatile and robust PC board assembly and manufacturing equipment that is suitable for applications ranging from low-volume prototyping to high-volume manufacturing. It is capable of positioning and connecting components on both the top and bottom of the board automatically. The system is highly customizable and can be configured to process boards of varying sizes and thicknesses, while maintaining accuracy throughout the production process. The unit consists of a high-precision pick-and-place head, a board-partitioning and fiducial alignment machine, and a solder jetting station. The pick-and-place head can be loaded with components such as surface-mount devices, resistors, capacitors, transistors, and connectors, and then accurately position and attach them to the boards. The board-partitioning and fiducial alignment tool allows for accurate segmentation of the board and alignment with fiducials, respectively. This ensures that the components are accurately placed and connected to the desired locations. The solder jetting station then applies a special wax-based solder to the board to create a permanent connection between the component and the board. The asset has a maximum cycle rate of 50 parts per minute, with a placement accuracy of ±0.004 inch. It also features an auto-teach model, which allows it to quickly store the location and orientation of components within the machine's memory for reliable and consistent results. The machine is also equipped with a vision equipment that can detect defects in components that are hard to detect with the naked eye. JOT AUTOMATION systems are designed for environments with limited space and can be easily integrated into an existing production line. The system is also easy to set-up, operate, and maintain, making it an ideal choice for manufacturing applications that require high accuracy, repeatability, and reliability.

There are no reviews yet