Used JOT / ELECTROBIT J218-11.4/16 #9084725 for sale

URL successfully copied!

Tap to zoom

ID: 9084725

Vintage: 2002

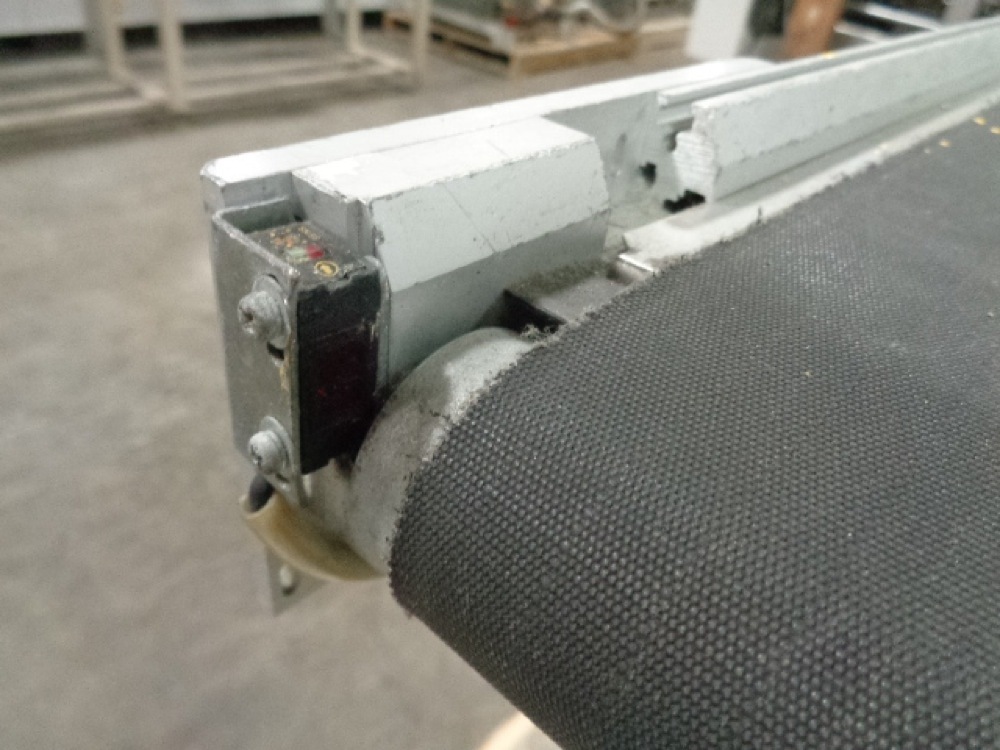

Flat belt conveyor, 79"

21.5" Belt width

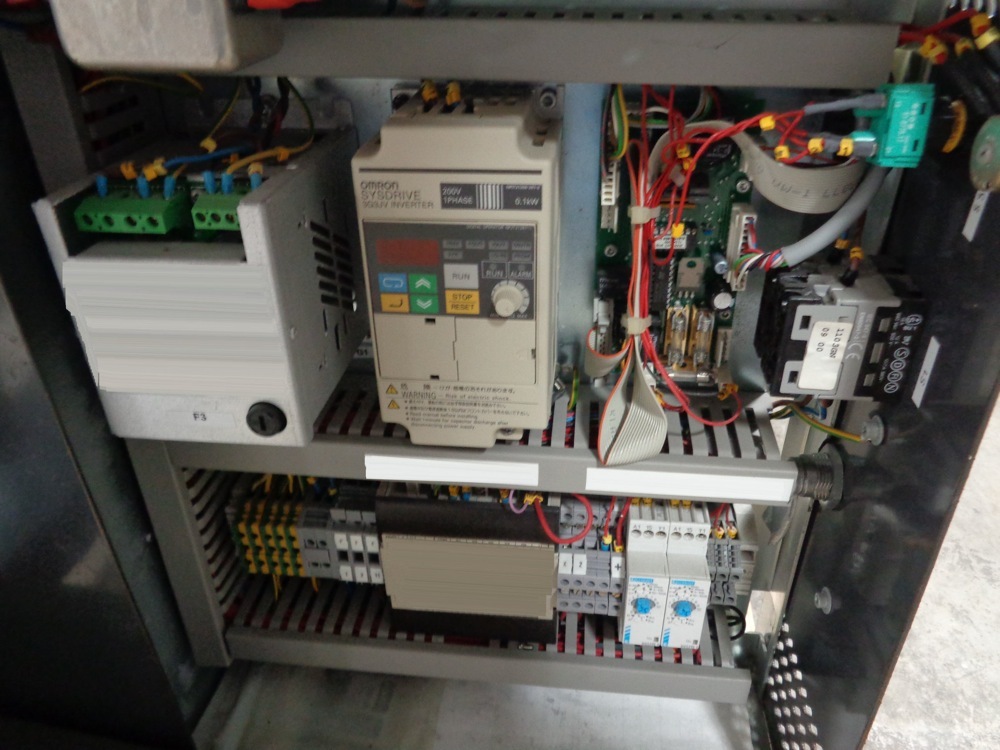

110V, 3A, 60Hz

2002 vintage.

JOT J218-11.4/16 is a versatile and comprehensive printed circuit board (PCB) assembly and manufacturing equipment. This system combines automated circuit board assembly and inspection with manual rework and board repair, providing users with a comprehensive and efficient production unit. The machine is designed to work with a range of materials for PCB fabrication, including FR4, ceramic, and Kapton. It includes a range of sensing add-ons such as inline and offline automated optical inspection (AOI) and automated X-ray inspection (AXI) to ensure boards meet customer specifications. The tool also includes advanced component placement capabilities for pre-stacking, pick and place, and soldering processes. It supports components ranging in size from 0402 chip components up to a maximum height of 15mm and 70mm in length/width. The component placement is supported by high accuracy and speed. The asset's soldering includes both reflow and wave soldering for through-hole and SMT components. It includes two high-speed IR soldering heads, with an adjustable temperature range of up to 480°C. This further facilitates fast, high-precision soldering. The model also features a pneumatic rework station with a hotplate option for temperature controlled soldering, as well as a desoldering setup, X-Y stage, and vacuum equipment for manual rework of components. ELECTROBIT J218-11.4/16 offers a simple and easy-to-use graphical user interface (GUI), which facilitates the setup and operation of the system. The software supports multiple functions, can be used for programming, parameter setting, maintenance, and diagnostics. It also supports operations such as program downloading, parts management, data collection, and production control. Overall, JOT / ELECTROBIT J218-11.4/16 is a comprehensive and efficient PCB assembly and manufacturing unit. It facilitates the automation of various processes, ensuring a high quality for assembled PCBs. In addition, it provides users with a GUI and multiple software supporting features, enabling comprehensive production monitoring and data control. This machine is a great solution for the cost-effective and efficient production of PCBs.

There are no reviews yet