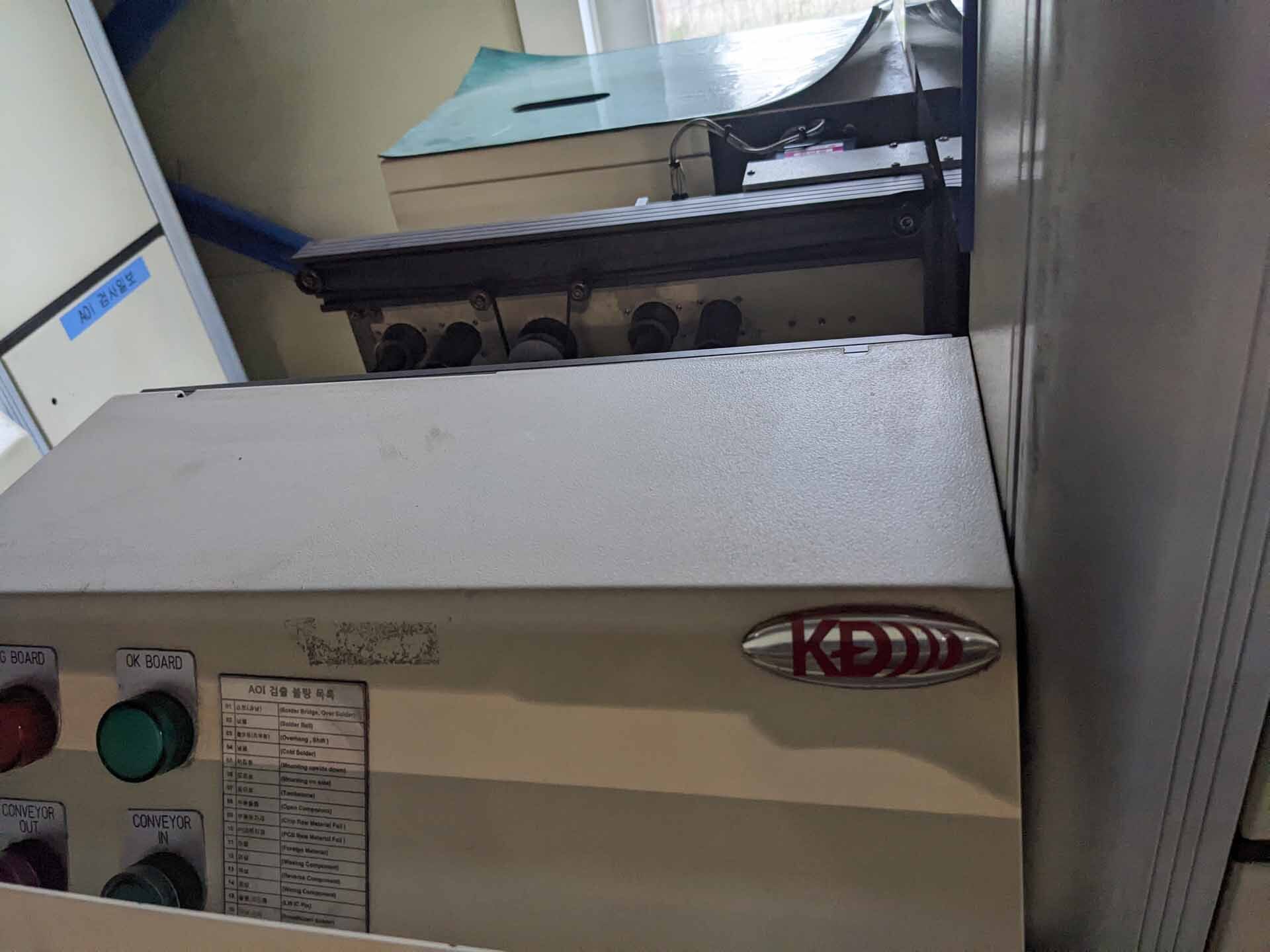

Used KD TEK KUD-12S #293604976 for sale

URL successfully copied!

Tap to zoom

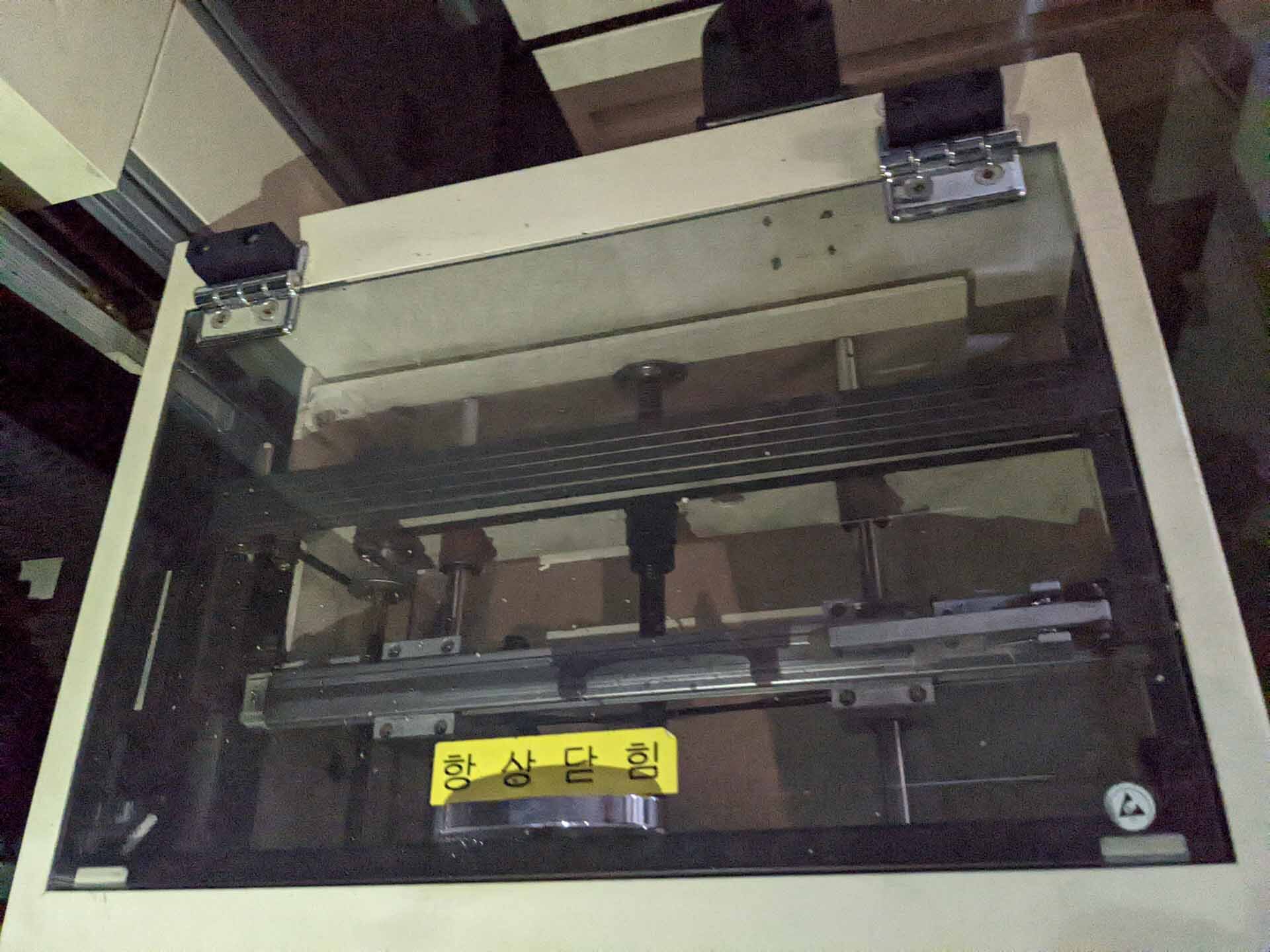

KD TEK KUD-12S is a process-controlled multi-element PC Board Assembly and Manufacturing Equipment, designed for high-volume, quick turn PCB Assembly and Manufacturing. This state-of-the-art system enables automatic organization and management of component and component-assembly knowledge, allowing a user to specify the programmable elements that define their production operations. Automation, high speed, and accuracy are key factors in KUD-12S unit, providing cost-effective, high yield production of all types of PC Board assemblies. Its modular nature provides for the maximum flexibility for user setup and configuration, with customizability to a diverse array of components and PCB resolutions. The machine utilizes a combination of text and graphical user interface (GUI) based programming and parameter input, allowing the user to develop efficient, accurate settings and parameters for each operation, while quickly locating knowledge related to components and component-assembly operations. The tool includes an advanced process controller that delivers an intuitive user experience and ensures accuracy and reliability throughout the board assembly process. Additionally, the advanced process controller provides options for both single-end manufacturing and multi-end manufacturing, ensuring best-in-class performance and cost-effectiveness regardless of your end-product requirements. KD TEK KUD-12S asset offers a comprehensive solution for assembly and testing of high-volume, quick turn PCBs. The model includes a thermal-resistive soldering head and a vacuum pick & place head, both driven by brushless motor technology. The motorized heads are designed to accommodate a maximum board size of 12 inches, and are capable of quickly moving between component and board locations, allowing for fast dispense and placement of all types of components. Additionally, the equipment includes an integrated vision inspection system, creating reliable process control and ensuring accurate assembly results. Moreover, the unit offers a comprehensive solution for operational testing and traceability. The on-board vision machine utilizes high-speed scanners to accurately record the location and type of all components, providing valuable product diagnostic and usage information. Furthermore, the tool includes a database which stores all of the component-information related to each board, providing a complete traceability throughout its entire lifecycle. KUD-12S asset is an extremely powerful and cost-effective solution for high-volume PCB assembly and manufacturing, significantly boosting production efficiency and yield. With its combination of automated process control, advanced features, and traceability capabilities, the model offers a reliable and efficient solution that meets the needs of users at many different performance and cost levels.

There are no reviews yet