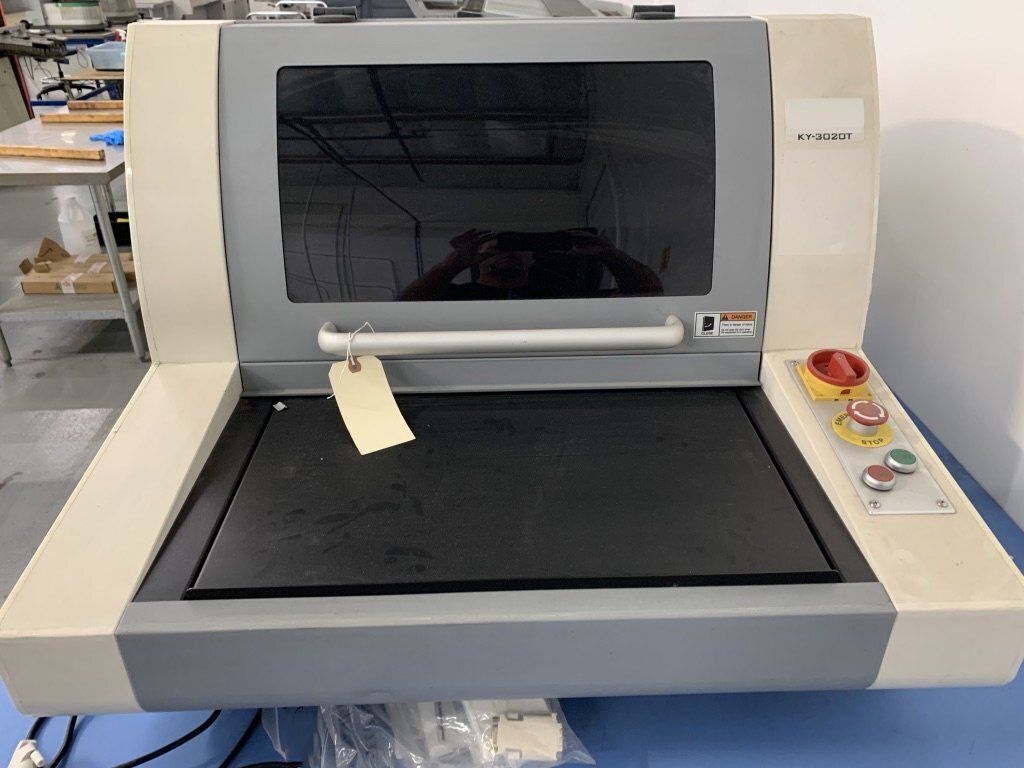

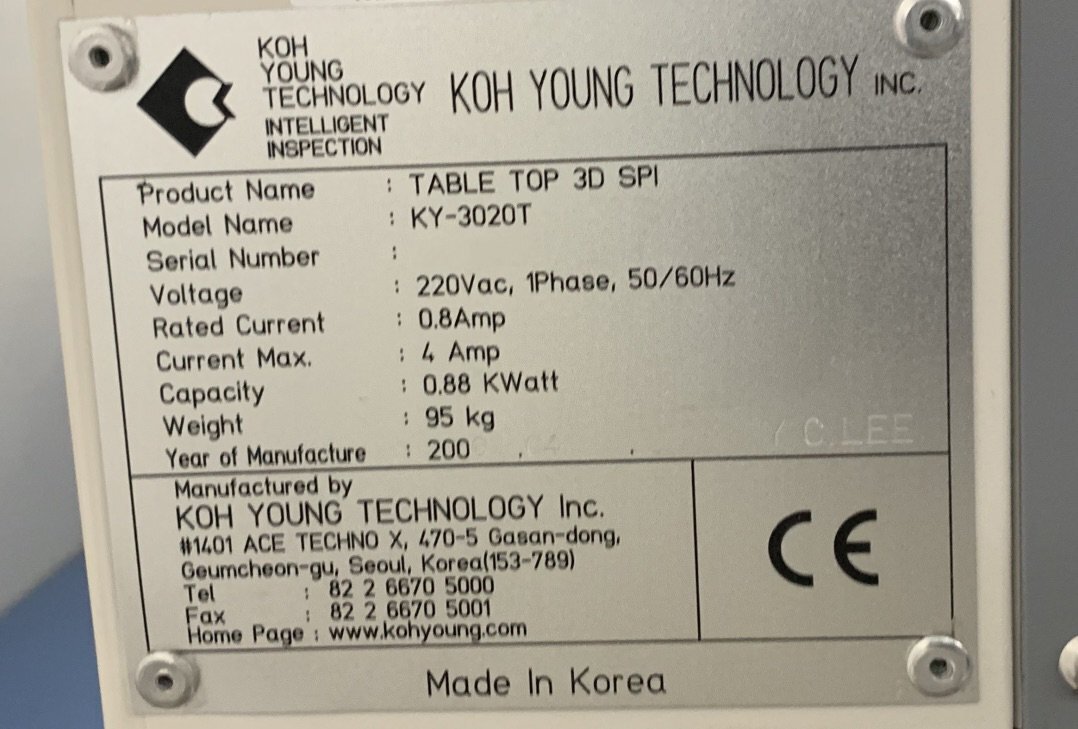

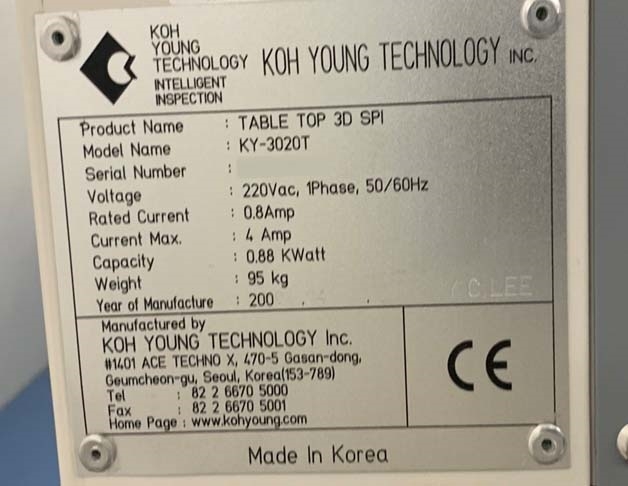

Used KOH-YOUNG KY 3020T #9271777 for sale

URL successfully copied!

Tap to zoom

ID: 9271777

Vintage: 2000

3D Solder Paste Inspection (SPI) system

Table top

(2) PC

2000 vintage.

KOH-YOUNG KY 3020T is a pc board assembly and manufacturing equipment designed for high-volume production lines. Its core features include a double-sided, 25-meter width line that automatically performs all the necessary operations needed for top-level assembly and production. The line features high-speed SMT (Surface Mount Technology) component placement, pick & place, PCB testing, as well as attaching a variety of connectors and cables. The core component assembly technology featured in KOH-YOUNG KY3020T is PCBA-in-line. This process enables a board to be quickly configured to a particular design specification and then automatically placed on the board for soldering. The line also offers a simplified 'one-stop' process, for customers looking for an efficient and cost-effective means of producing large-scale circuit boards. KY-3020T features an image-based centring system, giving the machine greater accuracy when positioning devices on the board than more traditional methods. It is capable of handling lead-free and hashed-PCB boards meanwhile, precision squeegee soldering means quality connections are made on both sides of each board. The machine is easily maintained with it's self-optimising control unit, which eliminates frequent adjustment settings and ensures that the assembly produces consistent quality results regardless of the type and number of parts being used. In order to maintain its optimal performance, the machine performs regular tool checks and maintenance cycles. KOH-YOUNG KY-3020T also features a number of automated testing functions to ensure quality assurance throughout the entire production process. These include multiple test functions such as open-circuit tests, short-circuit tests, insulation tests, leak tests, X-ray tests, and flying probes for post-process checks. By employing a fast, accurate, and reliable testing process, the machine guarantees each board is in perfect working condition before it leaves the production line. On one machine, KOH-YOUNG KY 3020 T can assemble and produce up to 26,000 components per hour. Furthermore, the asset is equipped with Autofeed, which improves productivity and reduces operator error, as well as the ability to store and recall up to 500 job data files. These features enable consumers to highly optimize their production process and maximize efficiency. In conclusion, KY 3020 T offers the perfect solution for high-volume circuit board production. It provides a combination of precision assembly capabilities, quality assurance, improved accuracy, and increased efficiency, all of which translate into higher yields, shorter turnover times, and improved customer satisfaction.

There are no reviews yet