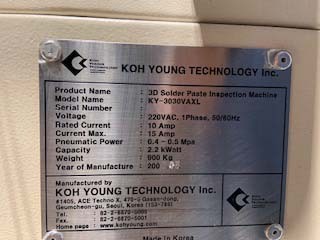

Used KOH-YOUNG KY 3030 VAXL #9409927 for sale

URL successfully copied!

Tap to zoom

KOH-YOUNG KY 3030 VAXL is a PC board assembly and manufacturing equipment designed to provide automated, high-accuracy inspection of components mounted on printed circuit boards (PCBs). The system is comprised of: a base unit, components modules, a pair of Digital Image Correlators (DICs) and a controller. KOH-YOUNG KY-3030VAXL unit is powered by a Siemens S7-1500 series PLC, enabling it to offer full inspection capabilities across all stages of the PCB production process. The machine is able to perform a variety of automated inspections and quality control checks of critical components. It is able to accurately scan board components such as resistors, capacitors, integrated circuits (ICs), connectors, switches and harnesses for errors. The tool's DICs use advanced patternrecognition technology to compare images taken of components and boards to predetermined reference images. Once the scan is complete, data from the scan is sent back to the controller for analysis. KY 3030 VAXL can also be used to quickly identify component abnormality or failure. Components can be inspected up to 6.25mm in size, while radius and circular components can be inspected up to 5mm in size. The asset's inspection accuracy is rated at 0.1mm, making it perfect for precise inspection work. Furthermore, its ball placement accuracy is rated at 0.15mm, allowing for extremely accurate component placement. The model also features advanced motion control, giving it the ability to quickly scan large volumes of printed circuit boards (PCB) in a short amount of time. It features an intuitive user interface and is highly configurable, which allows the user to customize their inspection process. Additionally, the equipment is equipped with a range of options such as component presence, component polarity, component value, component counterfeit detection and component absence detection. KY-3030VAXL is a versatile PC board assembly and manufacturing system that provides automated, high-accuracy inspection of components mounted on PCBs. Its advanced motion control, intuitive user interface and range of customized features make it a great choice for inspection and quality control of PCBs in all stages of production.

There are no reviews yet