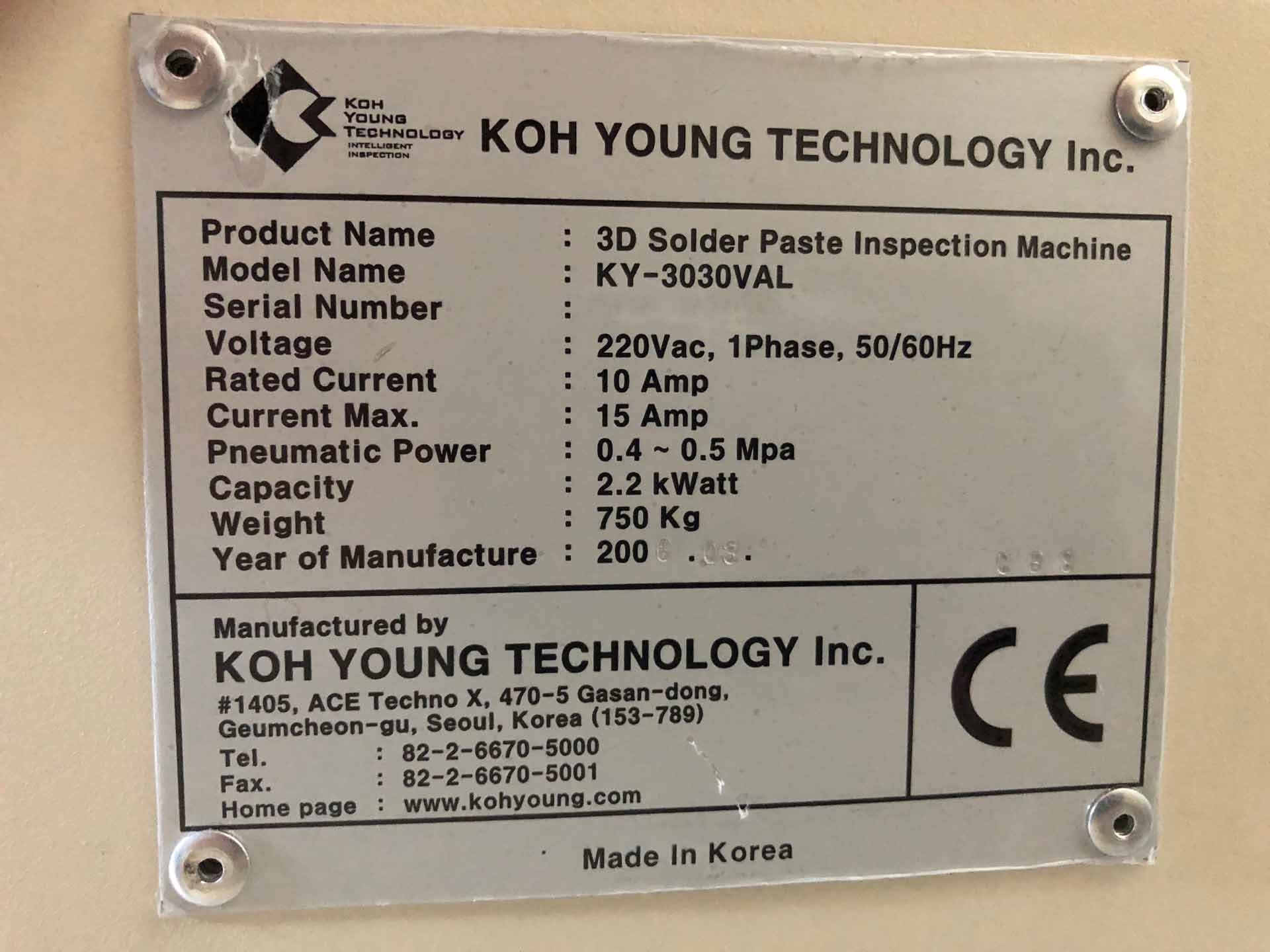

Used KOH-YOUNG KY-3030VAL #9211201 for sale

URL successfully copied!

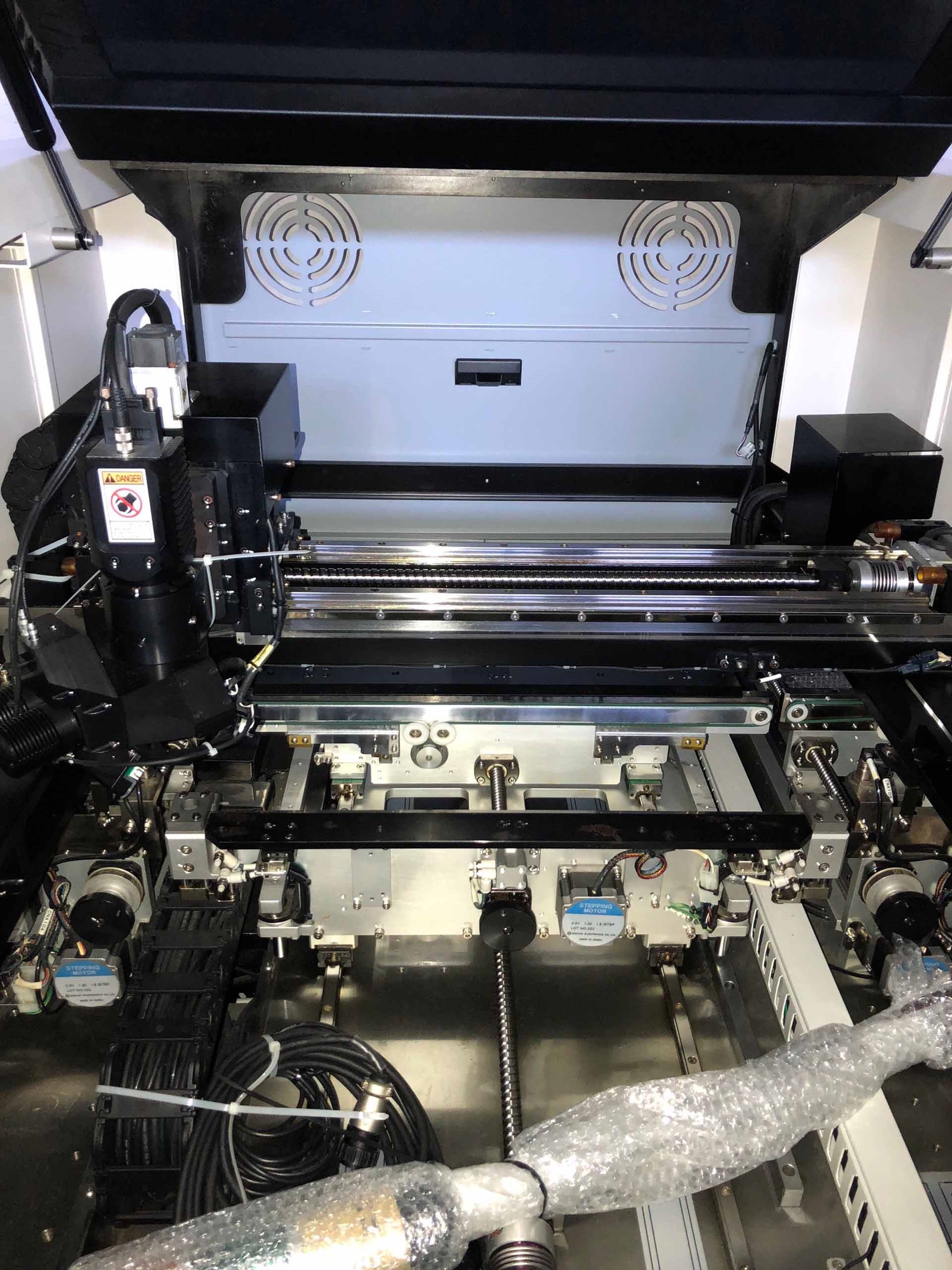

Tap to zoom

KOH-YOUNG KY-3030VAL automated PC board assembly and manufacturing equipment is an advanced solution designed to reduce costs and improve production efficiency. The system enables processors to manage and monitor multiple operations simultaneously, as well as maximizing production speeds while providing exceptional process control. KOH-YOUNG KY3030VAL unit is built on an open platform architecture, making it highly adaptable and customizable to fit various production environments. The machine utilizes an optimized four-zone conveyor design, which enables smooth and efficient board handling. With single-piece flow capability, KY 3030VAL is designed to reduce production time and overhead costs. KOH-YOUNG KY 3030 VAL also features high-speed servo controlled pick-and-place technology, equipped with a vision camera and a high-speed arm for precision placement. Through its intuitive user interface, it can accurately recognize components of all shapes and sizes, including complex ones. This ability enables it to provide high-precision placement with repeatability, as well as high-speed, accurate placement and fast production rates. KOH-YOUNG KY 3030VAL also includes an intelligent process monitor, which provides real-time control over the entire process. It has a built-in animation feature that provides a graphical view of the production process, including real-time component placement history. With this capability, process engineers can detect trends and identify potential areas for improvement and efficiency. KY 3030 VAL is also equipped with a high-speed processor to optimize production speed. It has an integrated board inspection feature, which allows users to determine component placement accuracy. It also includes an automated optical inspection capability from the pick-and-place area, allowing quick detection and removal of defective boards. KY3030VAL provides a comprehensive solution for PC board assembly and manufacturing. With its high efficiency and precise placement capabilities, the tool is well-suited to a wide range of manufacturing environments, from high-volume production lines to low-volume batch production. Furthermore, its intuitive user interface and advanced control capabilities make it an ideal solution for any business looking to reduce costs and improve production efficiency.

There are no reviews yet