Used KOH-YOUNG KY-3030VAL #9300215 for sale

URL successfully copied!

Tap to zoom

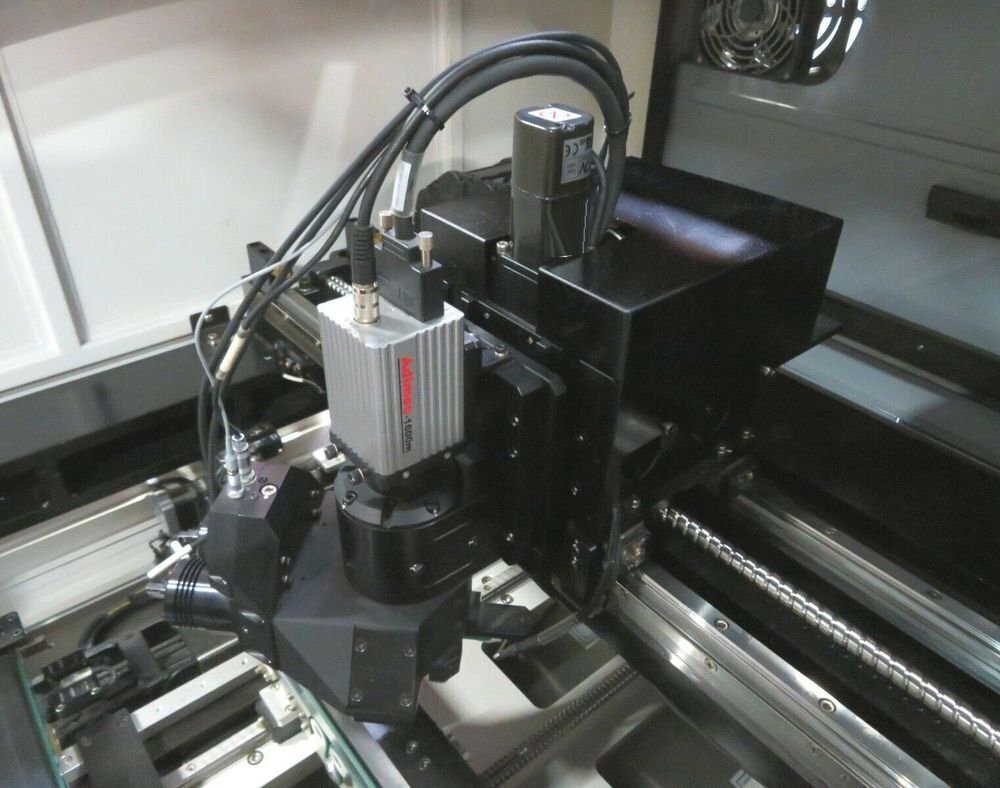

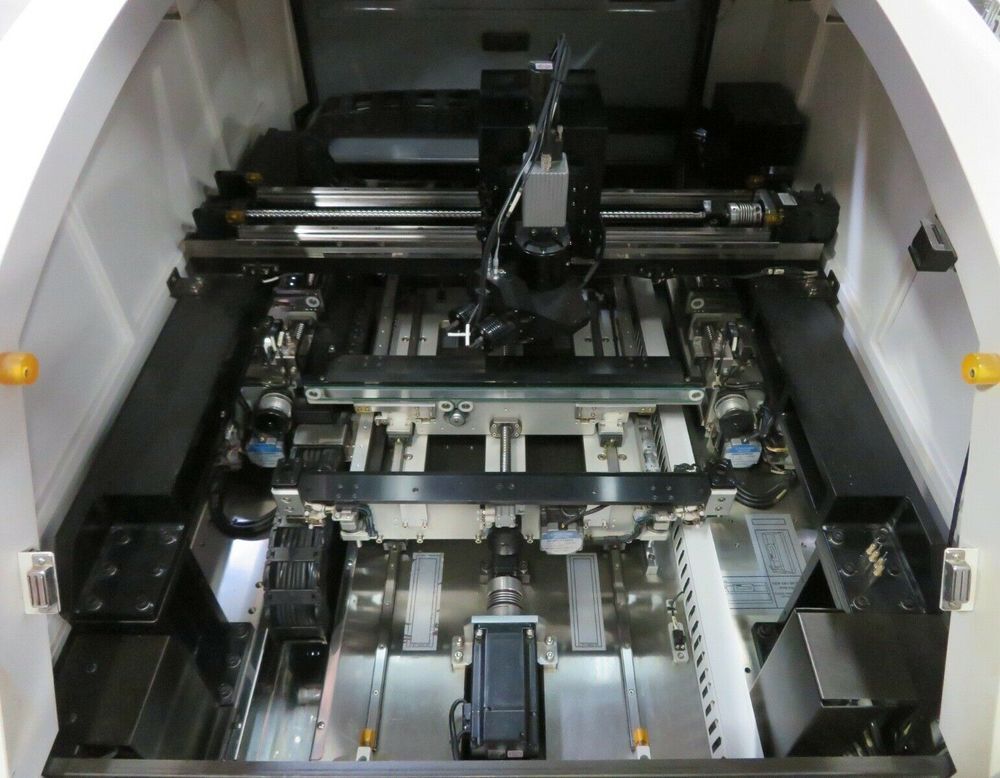

KOH-YOUNG KY-3030VAL is a top-of-the-line PC board assembly and manufacturing equipment that measures and inspects PCB boards and components accurately and efficiently. Designed to ensure repeatable quality control and optimum throughput, KOH-YOUNG KY3030VAL delivers reliable three-dimensional (3D) measurements and maximizes production reliability. This system's 3D measurements are based on the principle of optical triangulation, and are performed using a high-definition camera and a laser triangulation unit. Both optical and laser triangulation systems allow for the measurement of both components and boards together, as well as providing the precise 3D imaging of PCBs. This enables the user to accurately measure and record details such as component locations, board-level features, and soldering quality. It is also possible to assess the homogeneity of solder paste or flux coverage, as well as any shorts or open circuits present on the board. In addition, KY 3030VAL provides a complete range of post-manufacturing process tests, including solder paste volume, pin straightness, reflow profile, alignment, and surface mount technology (SMT) test capabilities. KY 3030 VAL also features two-dimensional (2D) vision technology for recognition of fiducials and board-level features to ensure uniformity and accuracy of process parameters. It can accurately measure the height, area, and volume of soldered components, as well as detect scratches, short circuiting, and misalignment of components. At the heart of KOH-YOUNG KY 3030VAL's operations is a powerful data-processing platform based on proprietary software. This software supports the automated control of various production processes and features, and runs a variety of customizable test programs. Moreover, it integrates a powerful artificial intelligence (AI)-based CAD feature, enabling it to quickly and automatically recognition components and process parameters. To conclude, KY3030VAL is an advanced PC board assembly and manufacturing machine that offers an unrivalled combination of accuracy and productivity. It offers a simple, yet comprehensive, framework to measure and inspect PCB boards and components easily and efficiently. It enables users to instantly identify faults and optimize their manufacturing processes, leading to increases in yields and reliability.

There are no reviews yet