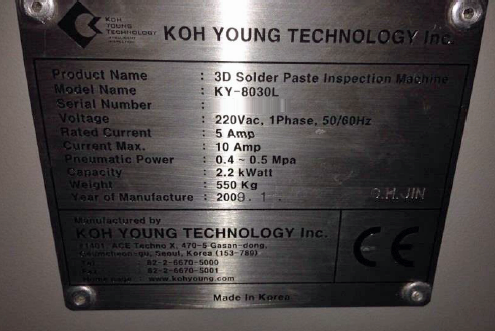

Used KOH-YOUNG KY 8030L #9099642 for sale

URL successfully copied!

Tap to zoom

ID: 9099642

Vintage: 2009

3D Solder paste inspection system

Camera pixel resolution: 20um

FOV size: 1.93 x 1.62"

Inspection time: 15.0 cm3/sec Standard

Min. paste deposit size: 150um Rectangle, 200um Circle

Height accuracy (on a KY calibration target): 2um

Optical system: 3D shadow free Moire and dual protection

PCB thickness: 0.016 to 0.20"

Max. PCB size: 20.08 x 20.08"

Max. PCB weight: 4.4lbs

220V

2009 vintage.

KOH-YOUNG KY 8030L is a highly sophisticated automated printing and assembly equipment designed for the precise manufacturing requirements of the PCB industry. This automated system features advanced vision and motion control capabilities, enabling consistent production of highly accurate parts assembly and prints. KOH-YOUNG KY-8030L features a unique vision unit designed to accurately inspect a variety of components, even those with intricate geometries. The vision machine uses a combination of laser measurement techniques to identify part features with precision, enabling measurement of dimensions, alignment, and orientation with extreme accuracy. Additionally, this tool utilizes global illumination in combination with high-speed cameras to create a bright imaging asset with uncompromised accuracy. KY 8030 L is equipped with a highly efficient motion control model featuring six individually-controlled axes, providing both the accuracy and speed necessary to meet the required production standards. This equipment is powered by a powerful servo drive system which is capable of producing up to 4.5 metres of travel per second without sacrificing accuracy. Furthermore, this automated unit is capable of operating with a wide range of materials, and supports the use of both standard and custom PCB artwork designs. KOH-YOUNG KY 8030 L is designed with a versatile computer-aided manufacturing (CAM) package, allowing users to customize process parameters to accommodate the specific requirements of PCB assembly and manufacturing. This machine supports the installation of various modules, such as software development tools, easy-to- use user interfaces, and controller settings. Additionally, KY 8030L integrates seamlessly with existing systems, allowing various PCB designs to be printed with consistency. Overall, KY-8030L is an advanced automated tool designed for the precise manufacturing requirements of the PCB industry. It features a unique vision asset designed to accurately inspect a variety of components, and a highly efficient motion control model capable of producing up to 4.5 metres of travel per second. This equipment is also equipped with an efficient CAM package that supports the installation of various modules, allowing users to customize process parameters for specific requirements.

There are no reviews yet