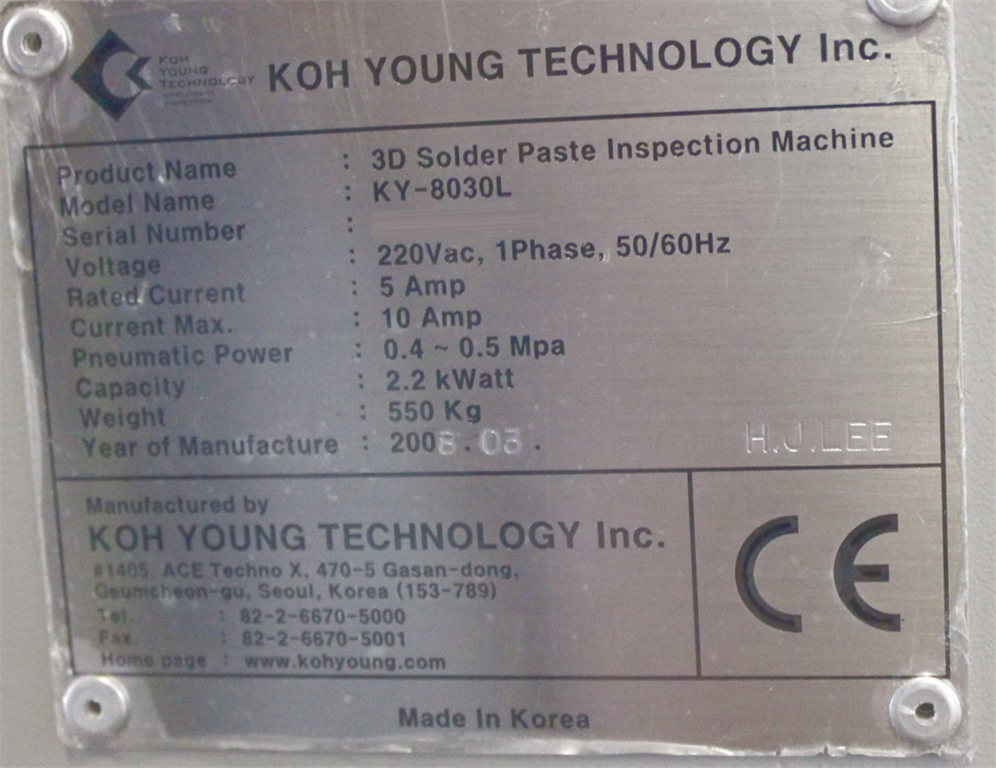

Used KOH-YOUNG KY 8030L #9111234 for sale

URL successfully copied!

Tap to zoom

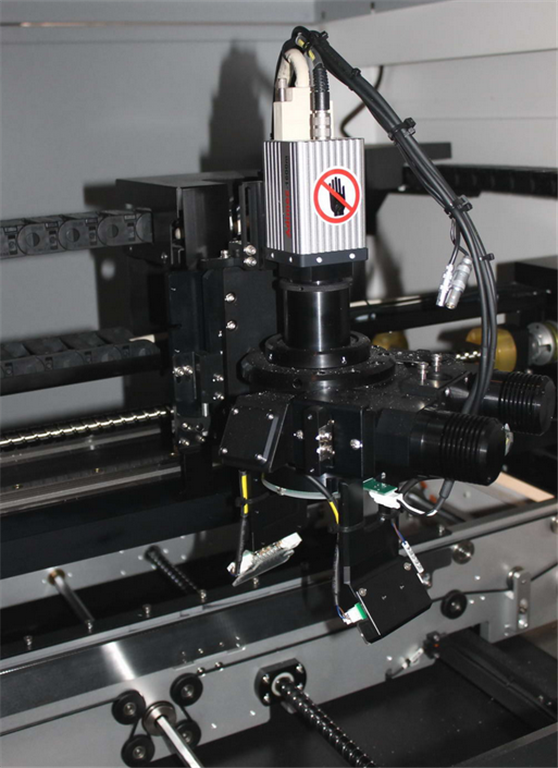

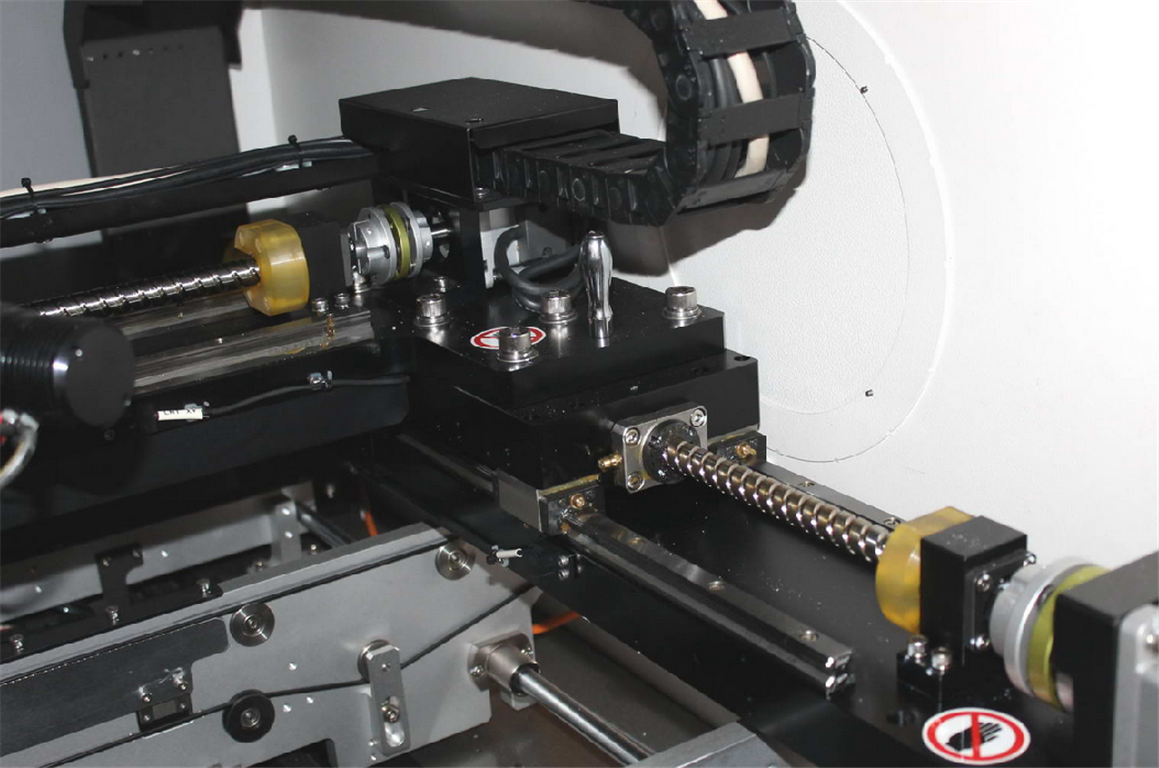

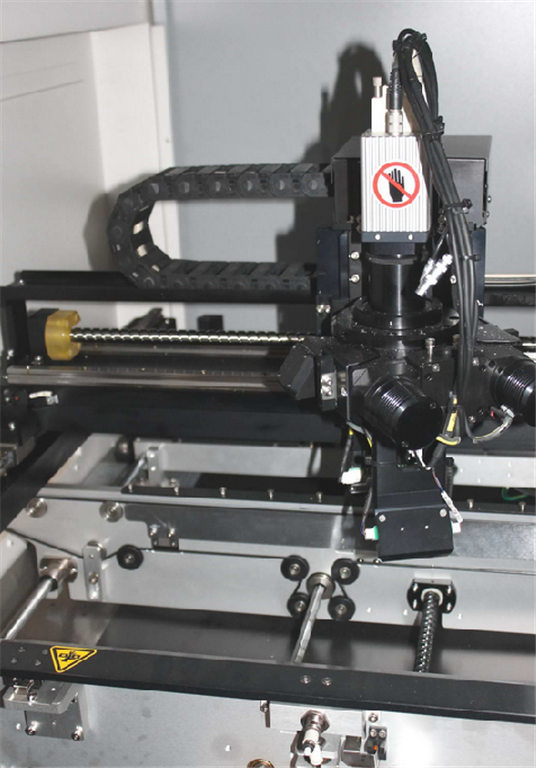

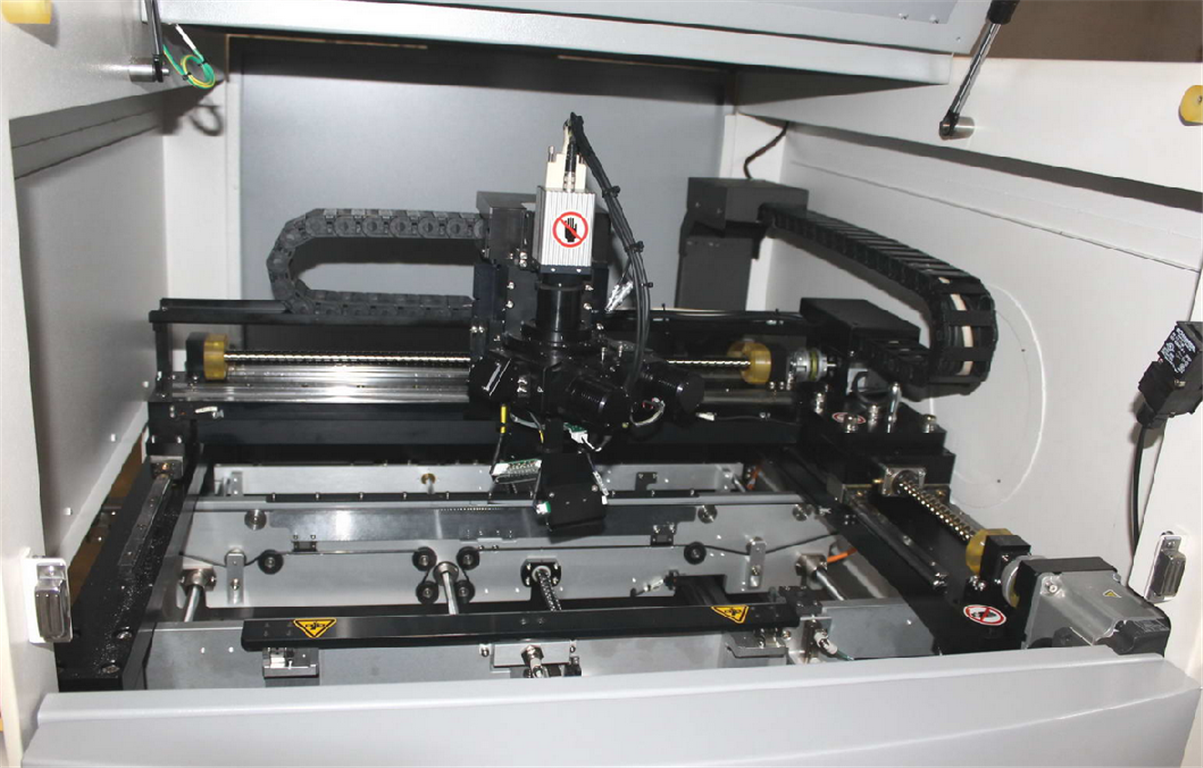

KOH-YOUNG KY 8030L is a highly-advanced PC board assembly and manufacturing equipment that optimizes quality control with its ultra-precise, high-speed inspection capabilities. It uses both AOI (Automated Optical Inspection) and AXI (Automated X-Ray Inspection) technology to examine boards and components to the highest level of accuracy. The system is designed for automated optical inspection (AOI) and X-ray inspection (AXI) of PC sections as small as 0.2 mm in size and provides real-time measurements and feedback, allowing an extremely high degree of accuracy. The analysis of the PC boards includes multi-dimensional measurements, defects and voids, bridge statuses, distortion, and shorts. The unit also inspects for solder pad size irregularities, solder pops, missing components, and wrong polarity problems. KOH-YOUNG KY-8030L utilizes a 9.3 megapixel, 16 bit color CCD camera, high-speed X-ray imaging machine, and 3D non-contact probe tool, in order to deliver accurate measurement results and improve the quality of the inspection process. The asset also features a multi-dimensional image display and a 3D graphic browser to reveal any hidden defects. In addition to its AOI and AXI capabilities, the model is also able to perform defect management operations, including defect re-measurement or improvement and classification, to improve the traceability of defective components and maximize productivity. KY 8030 L also features a wide range of automated PC board transport and handling capabilities. The equipment supports flexible board transport configuration including nearly any combination of single inline, drive-in, and part-in configurations. This makes it possible to utilize a variety of differing board sizes and configurations, reducing downtime associated with board changes. To ensure quality control and accuracy of components, KOH-YOUNG KY 8030 L offers a variety of specialized functions, including Near-Field-Communication Recognition, Bar Code Recognition, and Component Quantity Check. In addition, the system comes standard with an integrated on-board data collection unit that allows users to quickly and accurately track defect rates, component locations, and other production data. KY-8030L is an extremely powerful and efficient machine that enables manufacturers to keep their production costs low while ensuring the highest level of quality and accuracy for their products. Its advanced image processing capabilities, along with flexible transport and handling capabilities, make it an ideal choice for high-volume, high-precision PC board assembly and manufacturing.

There are no reviews yet