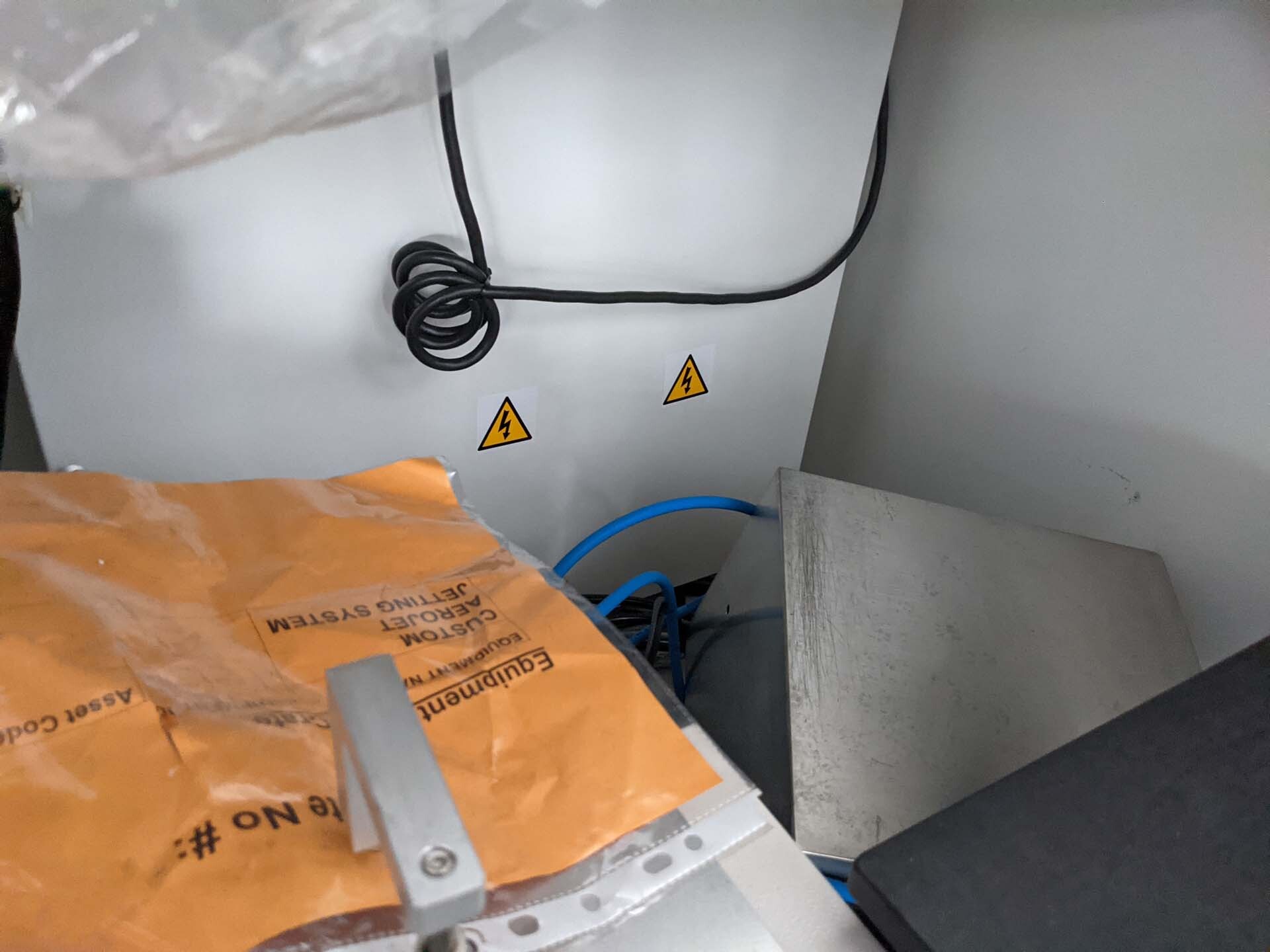

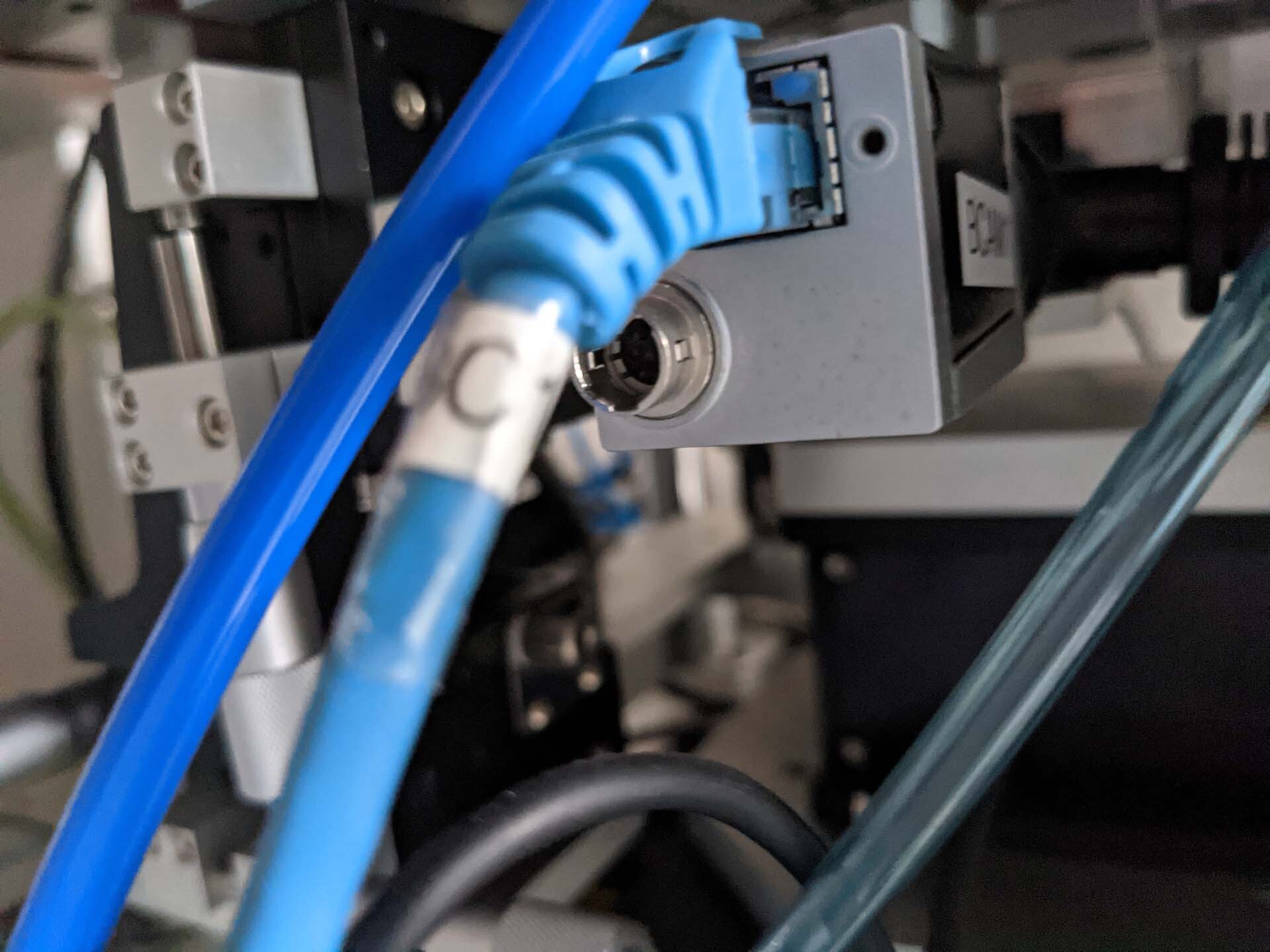

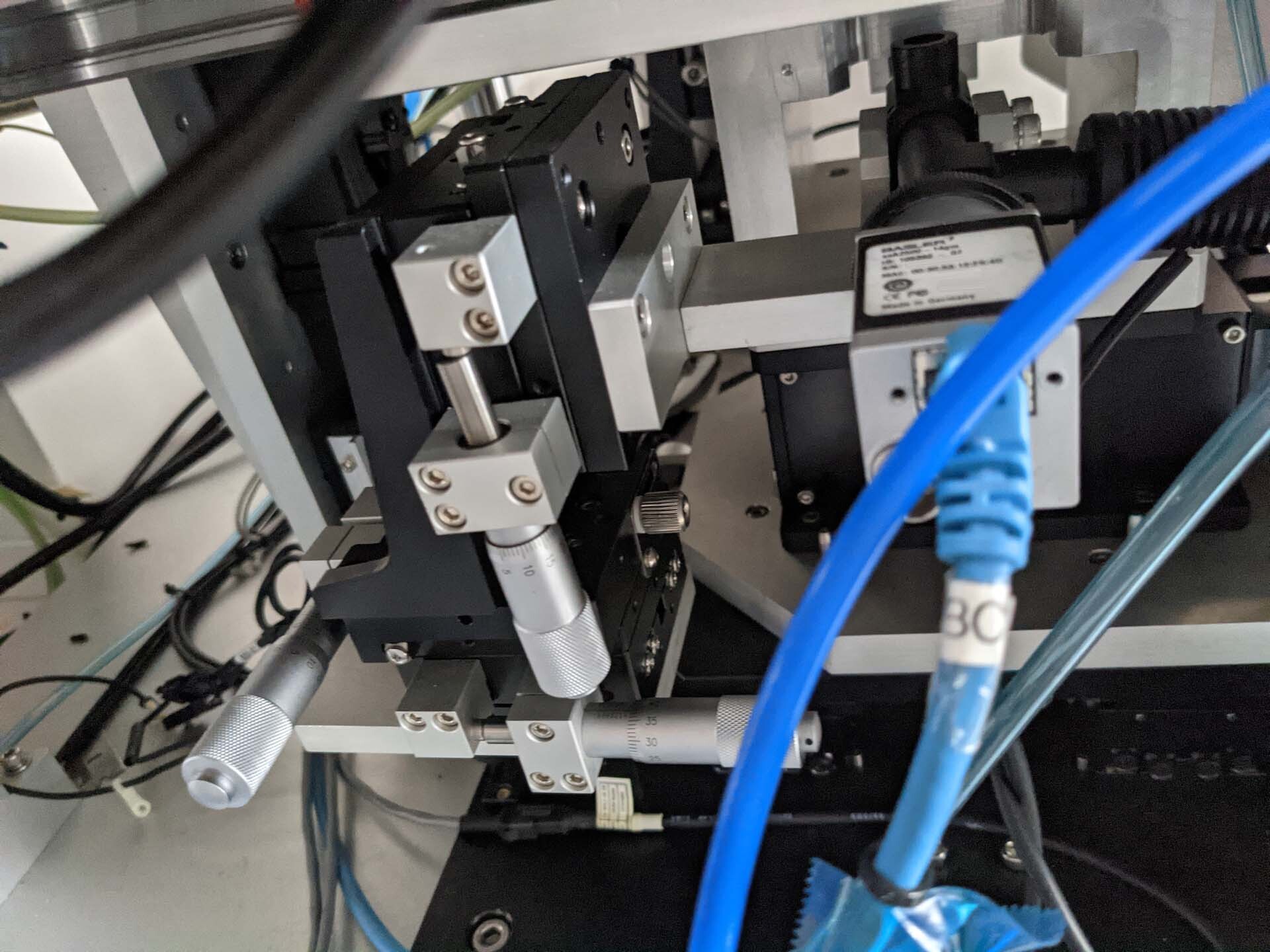

Used LASER VISION SYSTEM Wafer stacker #9394785 for sale

URL successfully copied!

Tap to zoom

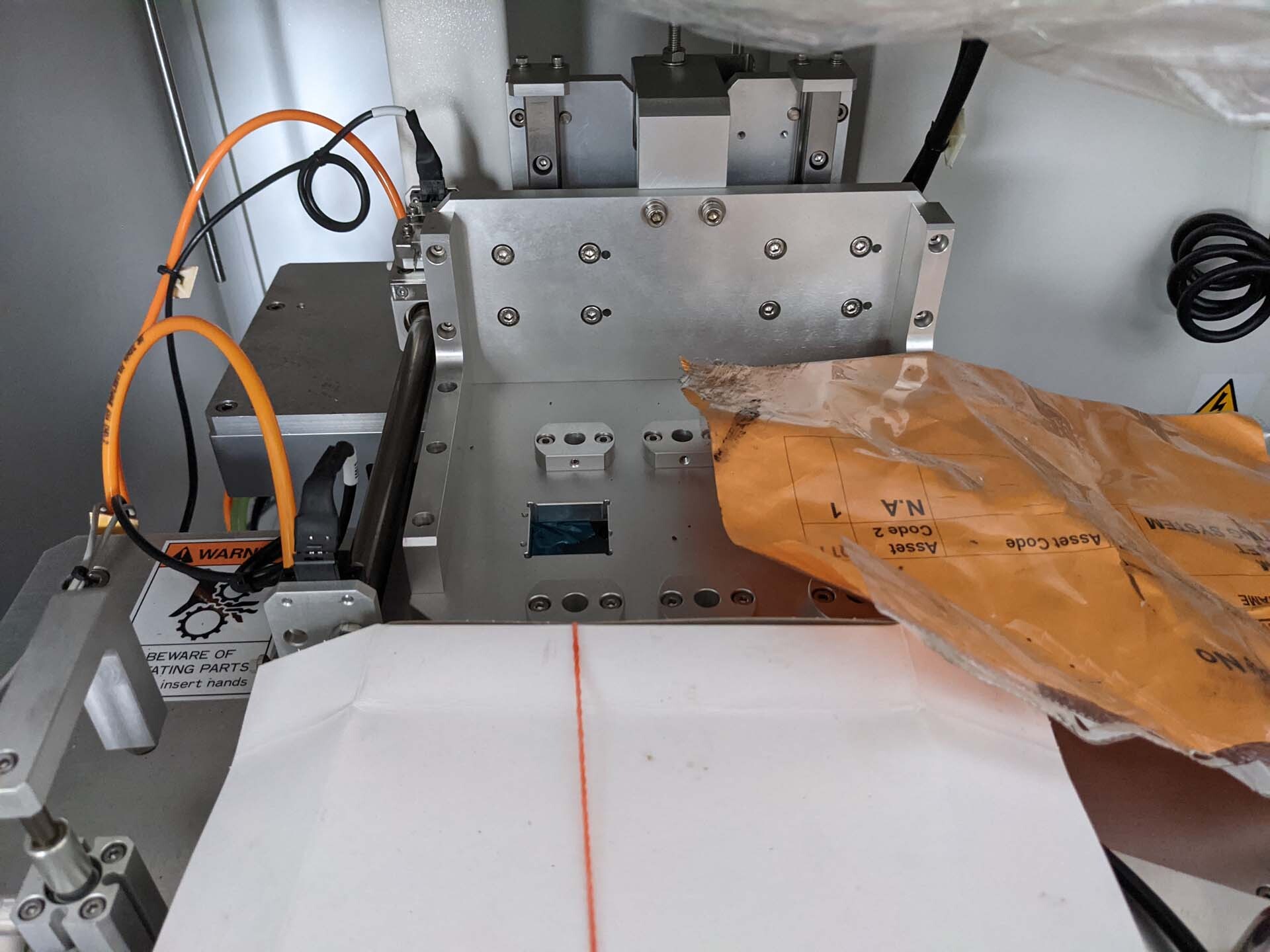

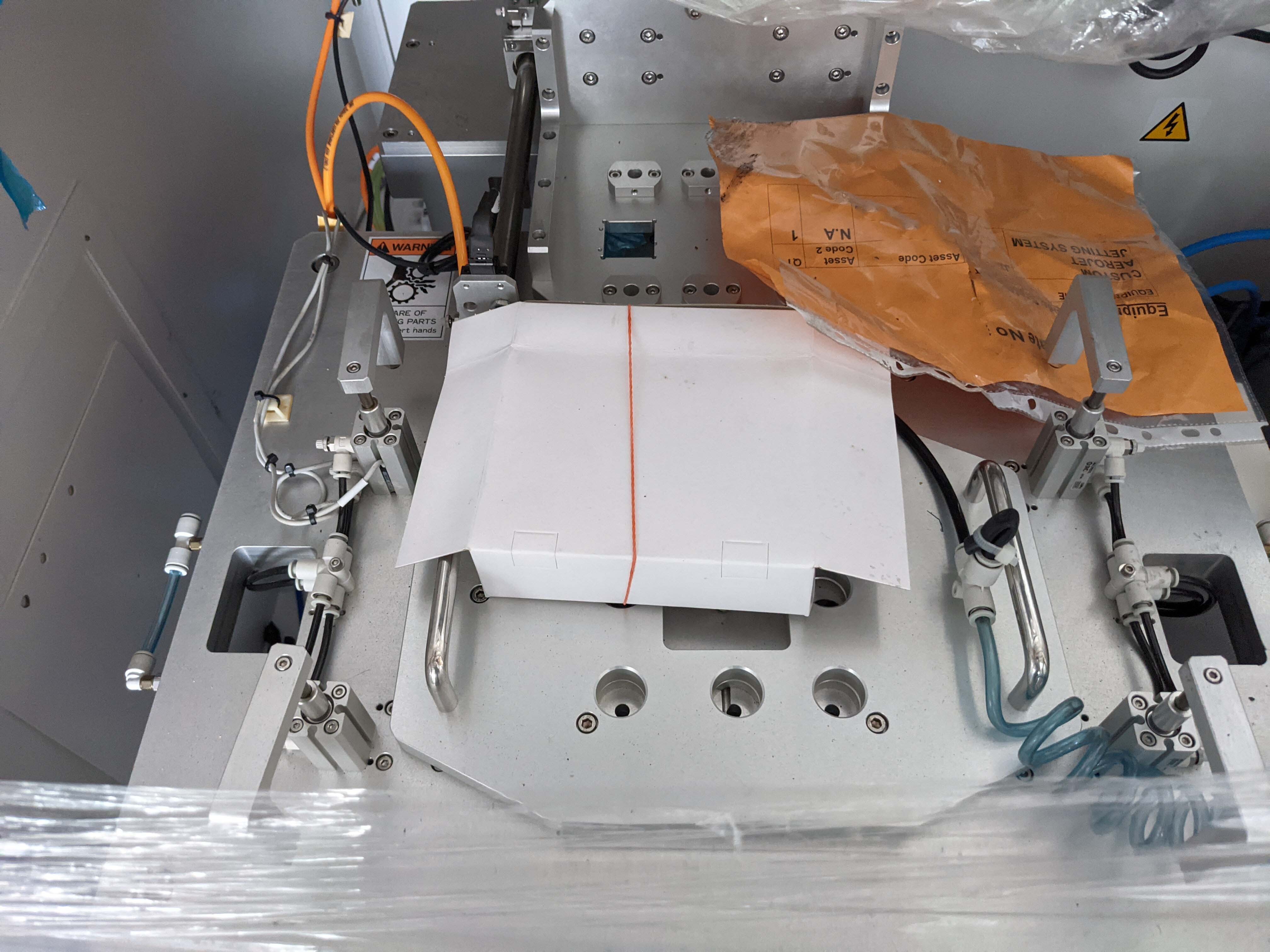

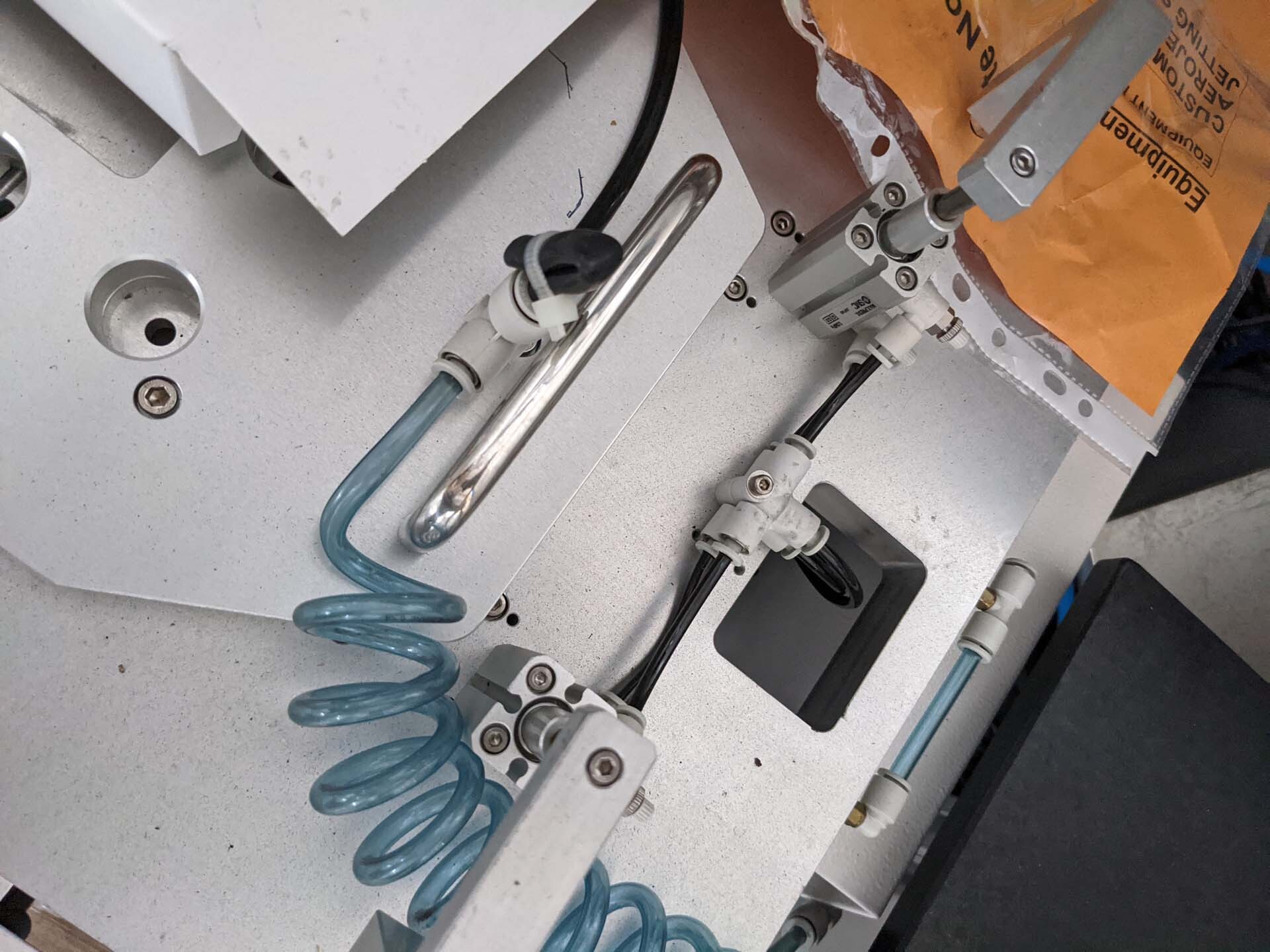

LASER VISION Equipment Wafer stacker is a next generation PC board assembly and manufacturing system designed to yield higher throughput and improved traceability. The unit features a LASER VISION Machine with an integrated overhead camera that captures an image of each component on the assembly line. The vision tool then automatically stacks and bolsters the components in the right order. The asset is designed for high-speed operation and can handle multiple types of components simultaneously. LASER VISION Model is designed to improve accuracy and speed on the production line. The camera captures an image of every component and then analyzes the image to ensure that its orientation and stacking order is correct. Once identified correctly, the component is moved into the correct place on the assembly line. This eliminates the need for manual sorting and counting, leading to increased throughput and accuracy. The vision equipment also increases traceability on the line. As the components move through the line, their images are captured and stored in a database. This way, any problems that occur in the assembly process can be identified easily and rectified if needed. Furthermore, the vision system eliminates manual labeling and handling, which significantly minimizes the chances of incorrect labeling or component orientation. Wafer stacker is compatible with current systems on the assembly line, making it easy to integrate into existing production lines. It is also incredibly easy to use, and there is minimal training required for operators. The unit is designed to be highly reliable and reduce downtime, so production runs can be finished quickly and accurately. Overall, LASER VISION Machine Wafer stacker is an ideal solution for improving throughput and traceability on the assembly line. It reduces the need for manual sorting and counting, helping to increase accuracy while decreasing downtime. It is also integrated with existing production lines, making it easy to roll out across multiple operations. Finally, the tool is designed to be reliable and efficient, so all production runs can be completed quickly and accurately.

There are no reviews yet