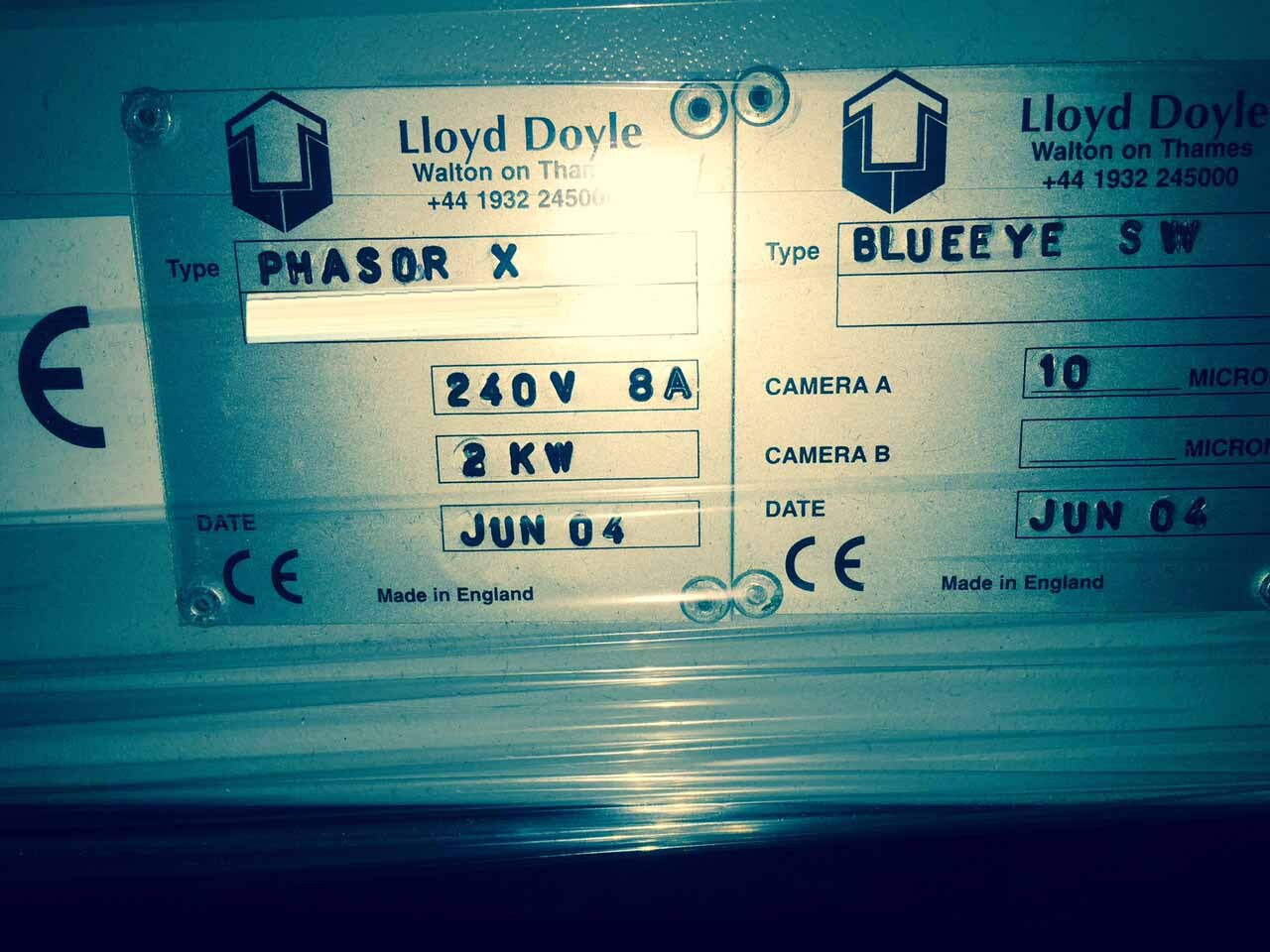

Used LLOYD DOYLE Phasor #9030260 for sale

URL successfully copied!

Tap to zoom

ID: 9030260

Vintage: 2004

Blue Eye SW Fluorescent / CCD based Automatic Optical Test (AOT)system

Panel size: 30” x 30” (760mm x 760mm)

Inspection size: 20” x 25” (500mm x 635mm)

Dimensions:

1.71M W

2.85M L

1.6M H

Weight 2150 kgs

2004 vintage.

LLOYD DOYLE Phasor is a powerful pc board assembly and manufacturing equipment that is designed for maximum efficiency and cost savings in printed circuit board (PCB) production processes. It is made up of three main components: a Functional CAD System (FCAD), a Kinetic CAD Unit (KCAD), and a Virtual Fabrication Machine (VFS). The FCAD tool enables the user to quickly design PCB layouts, including the dimensions, wiring, and connections that will be applied to various components on the board. The KCAD Asset schematics can also be employed to provide theoretical insight into the potential operational performance of the board. The VFS then translates the design into the actual hardware of the board, allowing the user to physically place components on the board and test the viability of circuit pathways. Additionally, Phasor model supports the rapid production of PCB prototypes using automated setup and routing. This Automated Setup and Routing process (ASR) can be used to place various components, including resistance, capacitance, inductance and other components, onto the board. Through this equipment, the software can also quickly evaluate the components for operational performance and accuracy, allowing the user to determine areas for improvement. ASR ensures that the user has access to accurate information quickly, thus allowing for quicker production of prototype boards and improved operational performance. LLOYD DOYLE Phasor system also incorporates software solutions for all stages of production, including management, production, and testing. This comprehensive approach allows manufacturers to optimize their production process to ensure quality, cost savings, and improved time to market. In addition, the unit supports a wide range of components, allowing the user to place varying levels of complexity on the board. This provides versatility for a variety of applications ranging from low power to high power applications. In addition, the machine combines layer and placement optimization to ensure minimal material usage, and cost savings for the user. Phasor tool supports all of the necessary setup and production steps required for the production of PCBs, providing users with a comprehensive solution for building and testing their boards. The asset also offers enhanced error-checking functionality to speed up the testing process and identify potential problems within the board designs. Ultimately, this complete model enables efficient and accurate PCB production with maximum cost savings, quality, and time to market for users.

There are no reviews yet